Filtering core structure of filter

A filter and filter element technology, applied in gravity filter, loose filter material filter, filtration and separation, etc., can solve the problems of having to stop production for cleaning, short cleaning cycle, poisoning, etc., to achieve easy disassembly, convenient installation and disassembly, simple craftsmanship

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

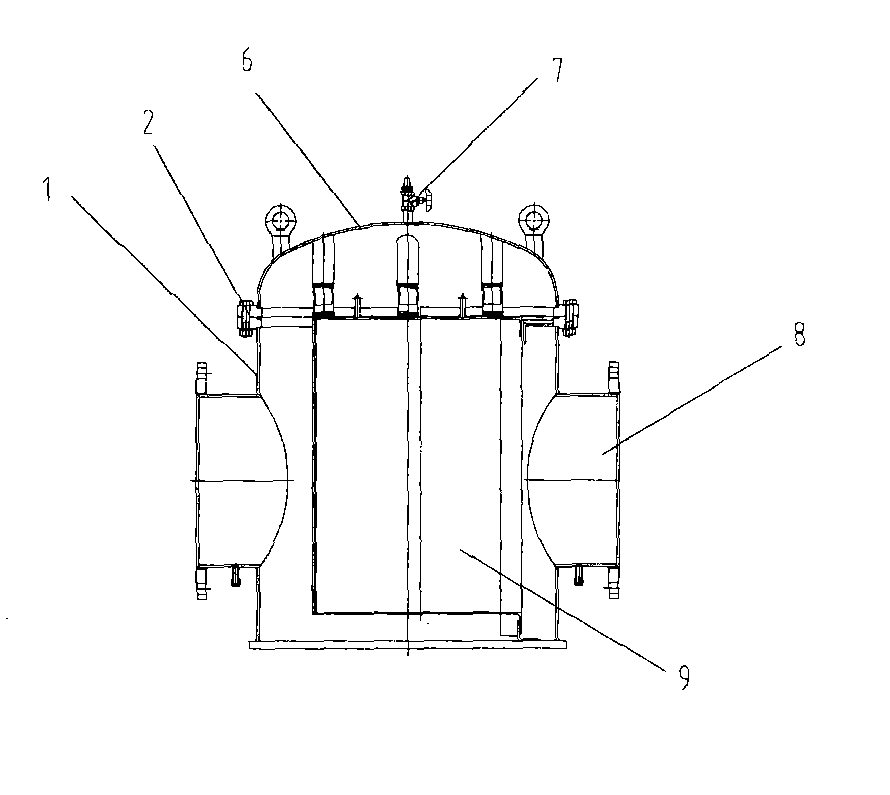

[0011] Such as figure 1 As shown, the present invention provides a filter core structure of a filter, comprising: cylinder body 1, upper housing flange 2, upper housing 6, exhaust valve 7, filtrate inlet 8 and filter component 9; filter component 9 is installed Inside the cylinder 1, the filtrate inlet 8 communicates with the filter element 9, the upper casing 6 is arranged on the upper end of the cylinder 1, the exhaust valve 7 is arranged on the top of the upper casing 6, and the upper casing flange 2 is fixedly connected to the upper casing 6 and barrel 1.

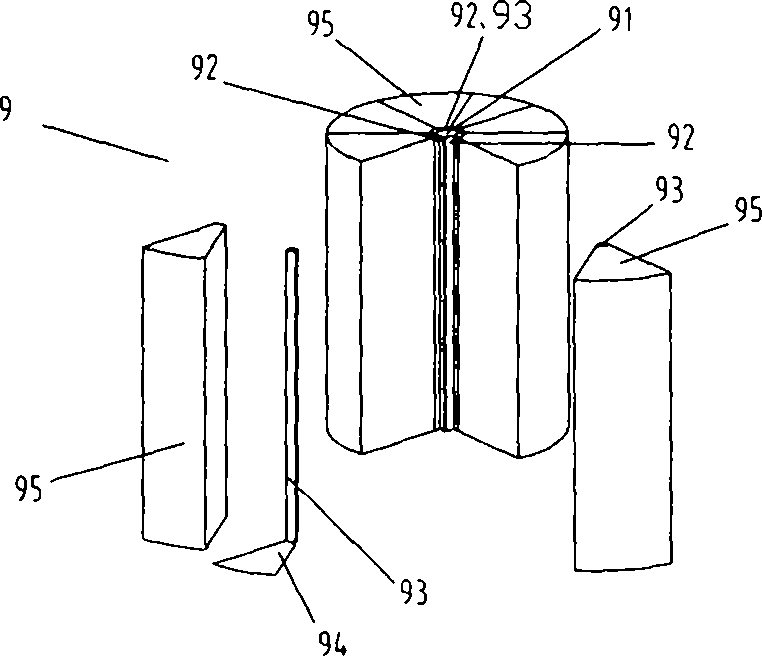

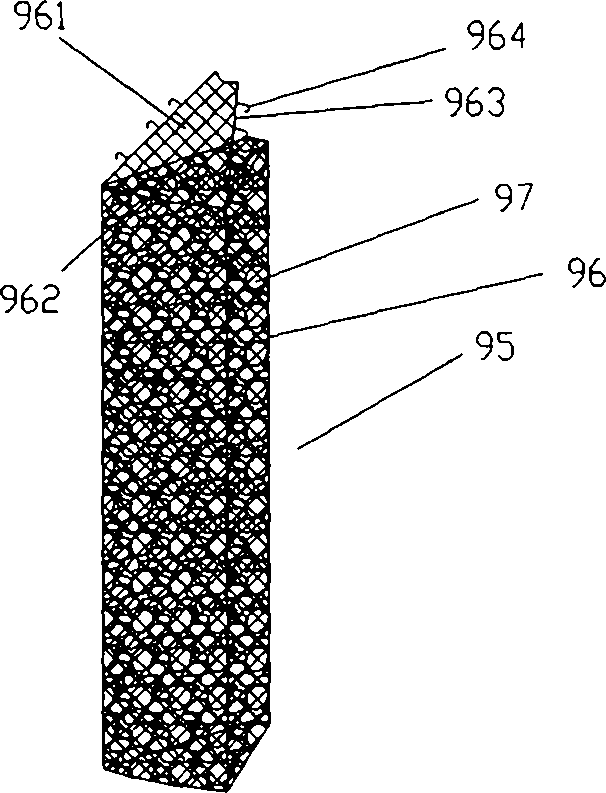

[0012] Such as figure 2 Shown: filter part 9 comprises a support rod 91, and the circumference of support rod 91 outer wall is evenly distributed with several vertical chute 92 separated by the vertical spacer that protrudes outwards, inserts in each vertical chute 92 There is a filter element pole 93, the bottom end of the filter element pole 93 is provided with a horizontal fan-shaped filter element support plate 9...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com