Double layer crusher

A crusher, double-layer technology, applied in the direction of wood processing equipment, grain processing, manufacturing tools, etc., can solve the problems of inability to achieve crushing, achieve the effect of improving crushing efficiency, stable rotor operation, and convenient disassembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

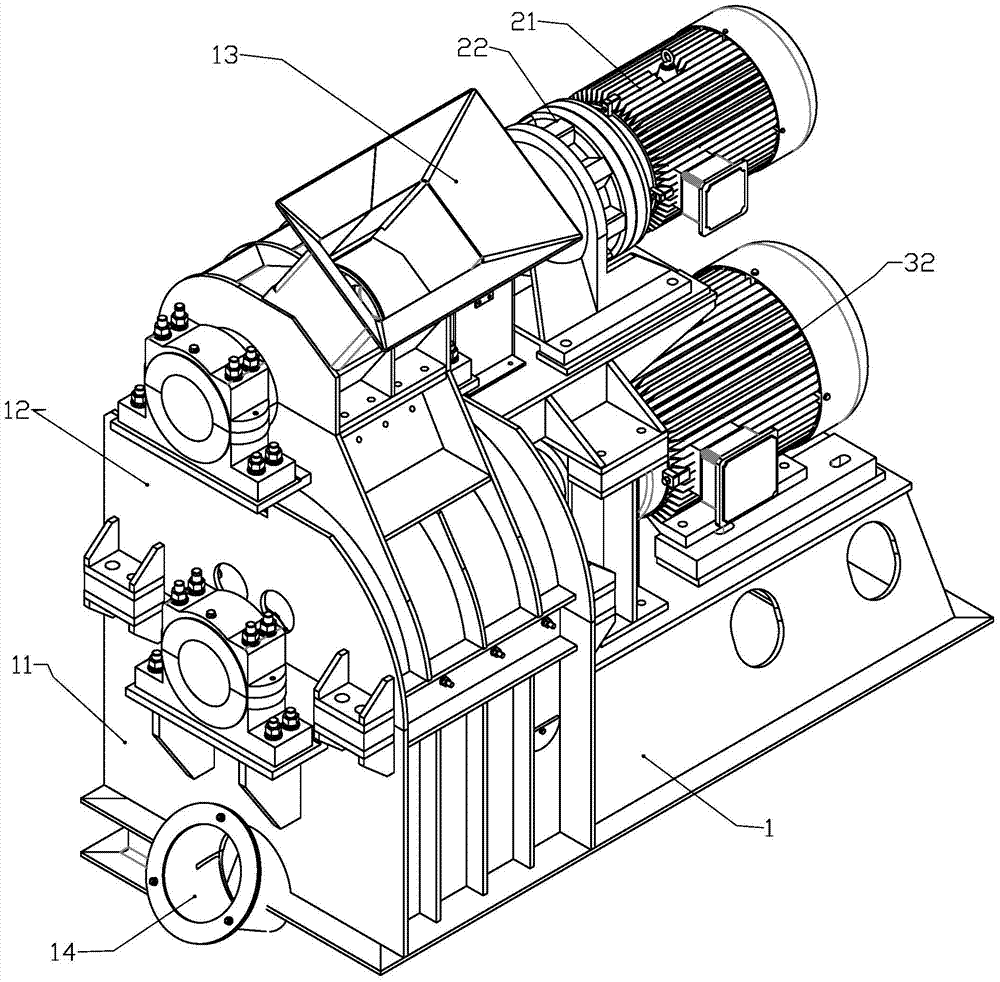

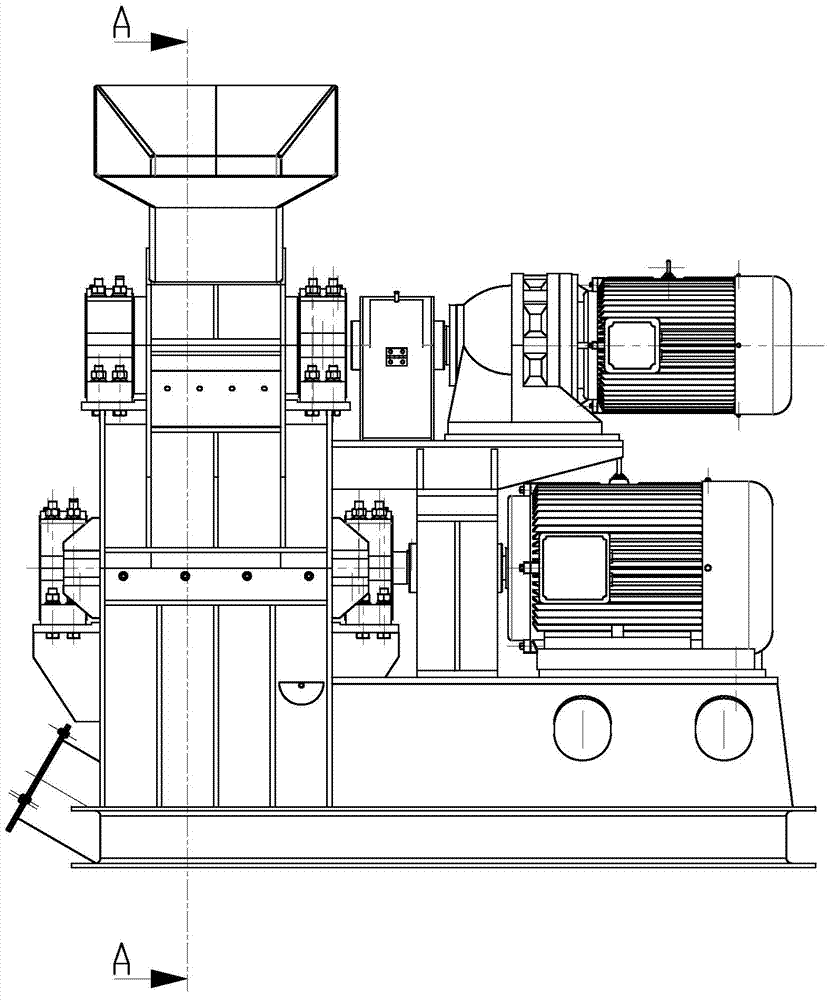

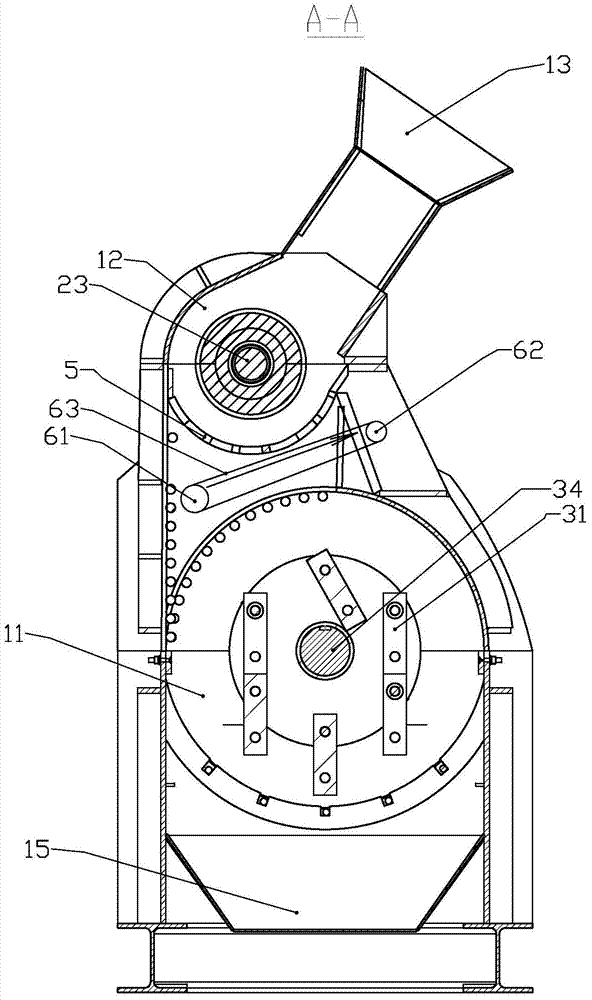

[0019] Such as Figure 1 to Figure 4 as shown,

[0020] A double-layer crusher consists of the following parts.

[0021] The machine base body 1 used for support, a crushing chamber 11 is fixed on the machine base body 1, a crushing chamber 12 is arranged above the crushing chamber, the crushing chamber 11 and the crushing chamber 12 communicate with each other, and in the crushing chamber The top of 12 is provided with a feeding port 13, and the feeding port 13 is arranged obliquely. One is to facilitate feeding, and the other is to improve the crushing efficiency to the greatest extent. A discharge port 14 is drawn outward, and the discharge port is sideways upward. During use, the discharge port 14 is equipped with a negative pressure fan, which is used to draw out the pulverized material in time to form an air flow channel. The base body 1 plays the role of connecting and supporting the various parts of the pulverizer to form a whole. It is formed by cutting and welding ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com