Coaxial sleeve dust collection plate type electrostatic dust removing machine

A technology of electrostatic dust removal and dust collection plate, applied in electrostatic separation, electrode structure, electrode cleaning, etc., can solve problems such as complex structure, and achieve the effect of increasing dust collection area, enhancing function and stability, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be described in further detail below in conjunction with the embodiments in the accompanying drawings, but this does not constitute any limitation to the present invention.

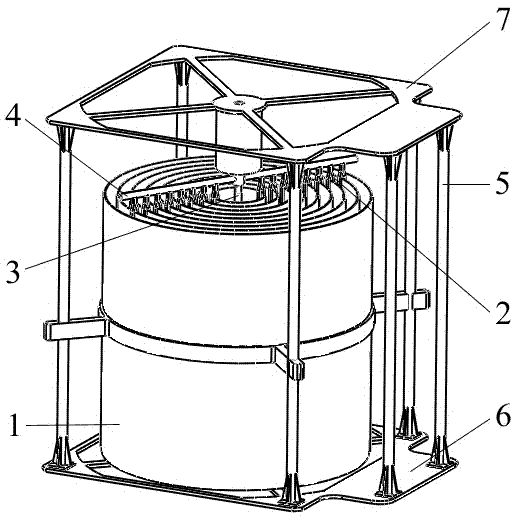

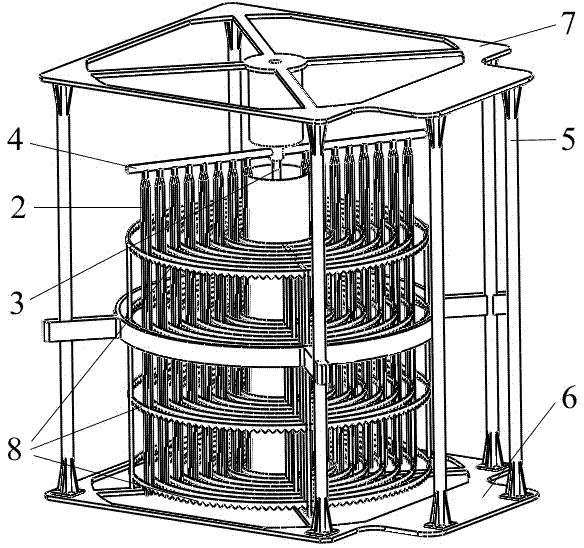

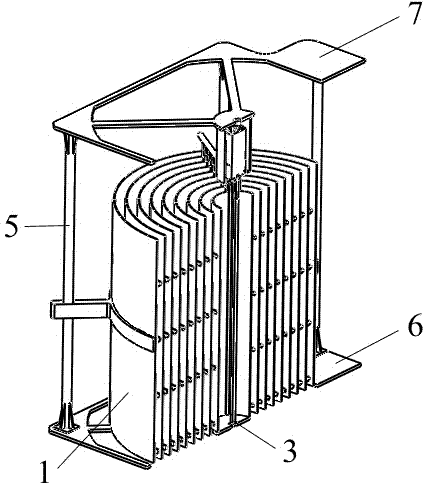

[0023] Such as Figure 1 to Figure 4 As shown, the coaxial sleeve dust-collecting plate-type electrostatic precipitator includes a dust collector with a dust-absorbing device. A dust-collecting electrode 1 and a discharge electrode 8 are arranged inside the shell of the dust-collector, and are connected to the dust-collecting electrode 1 and the discharge electrode 8. The configured high-voltage power supply device, in which the dust collecting electrode 1 is a group of coaxial sleeve-shaped multiple dust collecting plates, is characterized in that: the dust collecting plates are cylindrical, and the nine layers of cylindrical dust collecting plates are arranged coaxially, The diameter of the cylinder increases sequentially from the inside to the outside to form a cylindr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com