Automatic cleaning device and method for lens of outdoor optical facility

An optical facility and automatic cleaning technology, applied in chemical instruments and methods, cleaning methods and appliances, optics, etc., can solve problems such as blurring, affecting the perspective effect of protective cover lenses, inconvenient adding water or manual scrubbing maintenance, etc., to achieve feasible execution High reliability, easy to use and easy to understand, and the effect of protecting personal safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

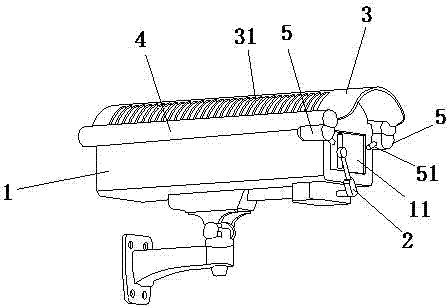

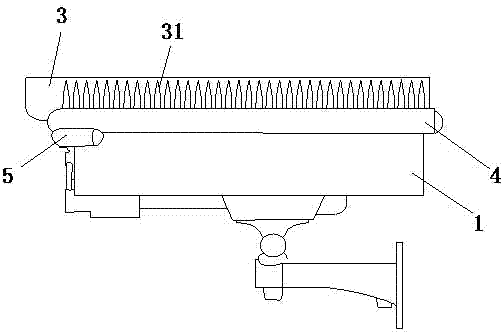

[0023] Embodiment one: if Figure 1~2 As shown, a camera lens automatic cleaning device includes a protective cover 3 arranged on the top of the camera 1, an electric wiper 2 arranged on the front lens 11 of the camera 1, the cross section of the protective cover 3 is arc-shaped, and the protective cover Both sides of the upper surface are provided with protrusions 31 at intervals, and these protrusions 31 are arranged in the axial direction, and the bottoms of the two sides of the protective cover 3 are respectively provided with collection grooves 4 along the axial direction, and the collection grooves 4 collect the gaps along the protrusions. Moisture flows down, the bottom of the front end of the collection tank 4 is provided with a water storage tank 5, the bottom of the water storage tank 5 is provided with nozzles 51, and the nozzles 51 are respectively arranged on the sides of the lens 11, and the entrance of the nozzles 51 is provided with a straight-through airtight ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com