Packaging container

一种包装容器、热塑性材料的技术,应用在散装化学品生产、分层产品等方向,能够解决能源浪费、原材料浪费等问题,达到颈缩现象减小、合格率高、保质时间长的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

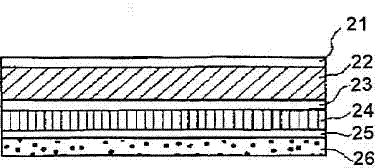

[0024] like figure 2 and image 3 As shown, a packaging container of the present invention includes the outermost layer 21 of thermoplastic material, the core layer 22, the middle layer 23 of thermoplastic material, the barrier layer 24, the adhesive layer 25 and the innermost layer 26 of thermoplastic material from outside to inside.

[0025] The adhesive layer 25 comprises metallocene catalyst polymerized linear low density polyethylene (MLLDPE) and low density polyethylene (LDPE), wherein the metallocene catalyst polymerized linear low density polyethylene (mLLDPE) has the following parameters: the average density is 0.88g / cm 3 ~0.925 g / cm 3 , Melt flow index (190℃, 2.16kg) is 5 g / 10min~20 g / 10min, peak melting point is 85℃~130℃, expansion ratio is 1.2~1.8; low density polyethylene (LDPE) has the following parameters: The average density is 0.90g / cm 3 ~0.925 g / cm 3 , Melt flow index (190℃, 2.16kg) is 5 g / 10min~20 g / 10min, peak melting point is 85℃~110℃, expansion ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com