Slag Portland cement and preparing method thereof

A technology of portland cement and slag, which is applied in the direction of cement production, etc., can solve the problems that cannot be used in fields with stricter hardness requirements, achieve short intervals between initial setting time and final setting time, high later strength, and improve hydraulic performance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

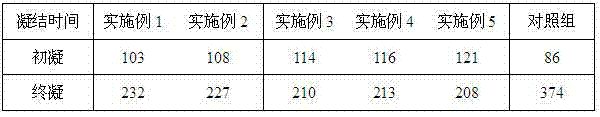

Examples

Embodiment 1

[0025] A kind of slag portland cement, comprises each component of following mass percentage:

[0026] (1) Portland cement clinker 30.0%;

[0027] (2) Copper slag 15.0%;

[0028] (3) Foundry pig iron slag 30.0%;

[0029] (4) Molybdenum 12.0%;

[0030] (5) Flue dust 8.0%;

[0031] (6) Desulfurization gypsum 5.0%.

[0032] Prepare slag portland cement according to the preparation method provided by the invention, the preparation steps are as follows:

[0033] (1) Material preparation: Accurately weigh each component according to the mass content of each component;

[0034] (2) Pulverization: Pulverize the copper slag, casting pig iron slag and molybdenum slag until the average particle size of the powder is 120um;

[0035] (3) Grinding: Mix the various components together according to the mass percentage and grind until the average particle size is 100um to obtain slag portland cement.

Embodiment 2

[0037] A kind of slag portland cement, comprises each component of following mass percentage:

[0038] (1) Portland cement clinker 65.0%;

[0039] (2) Copper slag 5.0%%;

[0040] (3) Foundry pig iron slag 15.5%;

[0041] (4) Molybdenum slag 5.5%;

[0042] (5) Flue dust 6.5%;

[0043] (6) Desulfurization gypsum 2.5%.

[0044] Prepare slag portland cement according to the preparation method provided by the invention, the preparation steps are as follows:

[0045] (1) Material preparation: Accurately weigh each component according to the mass content of each component;

[0046] (2) Pulverization: Pulverize the copper slag, casting pig iron slag and molybdenum slag until the average particle size of the powder is 120um;

[0047] (3) Grinding: Mix the various components together according to the mass percentage and grind until the average particle size is 100um to obtain slag portland cement.

Embodiment 3

[0049] A kind of slag portland cement, comprises each component of following mass percentage:

[0050] (1) Portland cement clinker 45.0%;

[0051] (2) Copper slag 10.0%;

[0052] (3) Foundry pig iron slag 20.0%;

[0053] (4) Molybdenum slag 10.0%;

[0054] (5) Flue dust 10.0%;

[0055] (6) Desulfurization gypsum 5.0%.

[0056] Prepare slag portland cement according to the preparation method provided by the invention, the preparation steps are as follows:

[0057] (1) Material preparation: Accurately weigh each component according to the mass content of each component;

[0058] (2) Pulverization: Pulverize the copper slag, casting pig iron slag and molybdenum slag until the average particle size of the powder is 120um;

[0059] (3) Grinding: Mix the various components together according to the mass percentage and grind until the average particle size is 100um to obtain slag portland cement.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com