Method for preparing isophorone diamine

A technology of isophorone diamine and isophorone, applied in the field of preparing isophorone diamine, can solve the problems of low yield, long reflux time and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

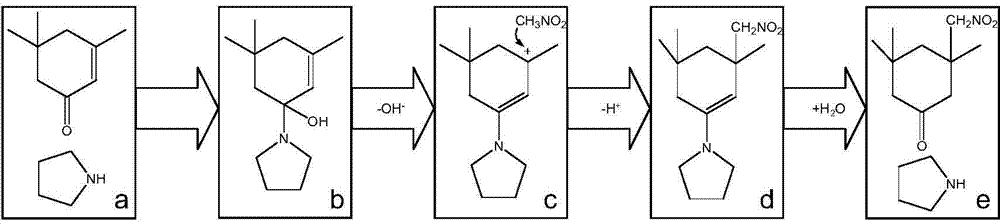

Method used

Image

Examples

Embodiment 1

[0036] Embodiment 1 Tetrabutylammonium fluoride as catalyst

[0037] In a 100ml glass bottle, add 10mmol of isophorone, 15mmol of nitromethane, and 1ml of tetrabutylammonium fluoride, react at 60°C for 1 hour, the conversion rate is 19%, and the conversion is 32% in 5 hours.

Embodiment 2

[0038] Embodiment 2 Tetrabutylammonium hydroxide as catalyst

[0039] In a 100ml glass bottle, add 10mmol of isophorone, 15mmol of nitromethane, and 5mmol of tetramethylammonium hydroxide, react at 70°C for 5 hours, and the conversion rate is 40%.

Embodiment 3

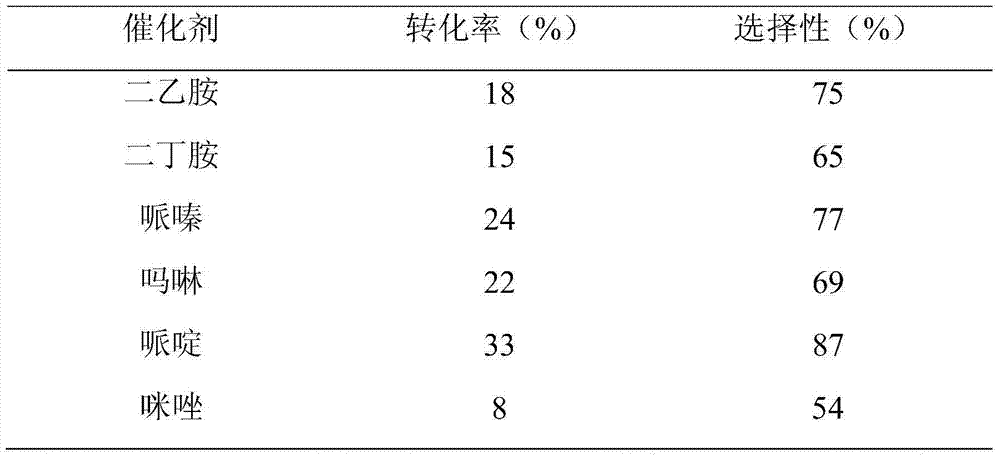

[0040] The catalytic effect of several secondary amines of embodiment 3

[0041]

[0042] Isophorone 10mmol, nitromethane 15mmol, catalyst 10mmol, reaction temperature 50°C.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap