High turbidity water intake dredging system and method thereof

A high turbidity and dredging technology, which is applied in water supply equipment, drinking water equipment, soil movers/shovels, etc., can solve problems such as easy sedimentation, increased turbidity of raw water, and inconvenient dredging, etc., to ensure that Stabilize, simplify management, and reduce the effect of cement and sand

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

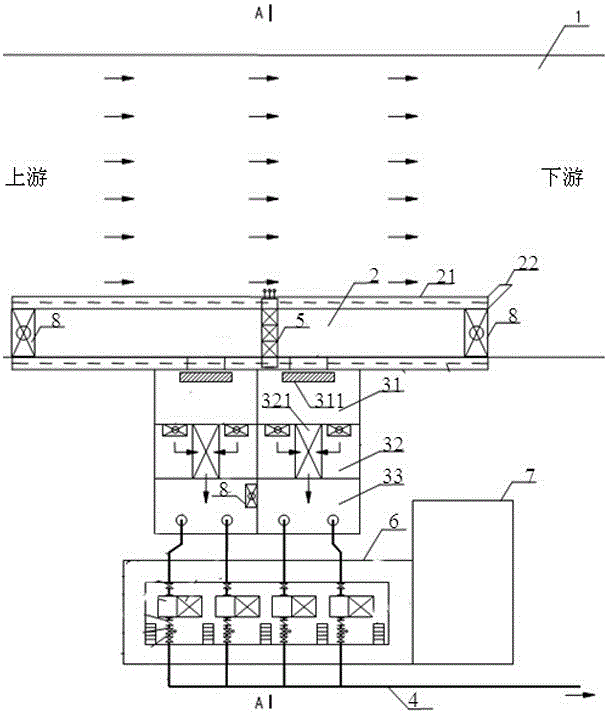

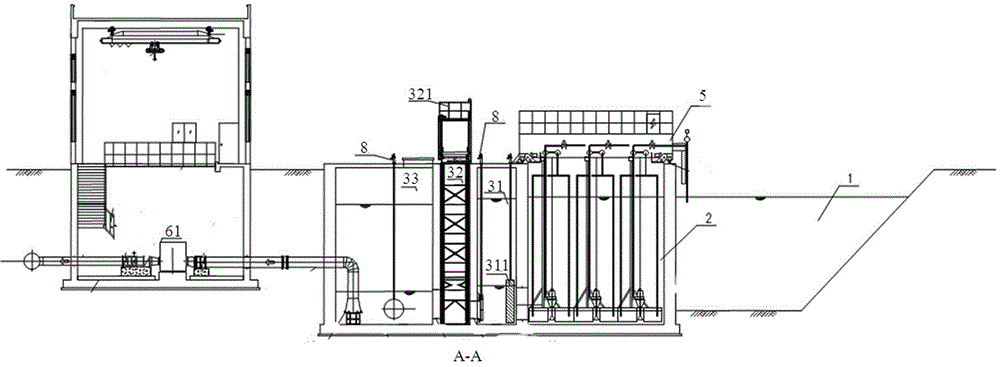

[0057] Such as figure 1 , 2 As shown, the present embodiment 1 is suitable for the water intake water body 1 is relatively wide, and the water intake water body management department allows the setting of the water intake rectification area 2 in the water body and allows the water intake pump room to be used under the situation of the water intake water body 1; In the water body 1, a water inlet and rectification area 2 is set near one side of the bank, and the middle part of the water inlet and rectification area 2 is connected with a water absorption well. The water pump 61 is located in the water intake pump room, the water pump room 6 and the power distribution room 7 are jointly built, and is connected with the water absorption well and the water purification plant through the pipeline system, and the water intake pump room 6 is also equipped with a motor, a lifting device, and a walkway , stairs and railings are connected to the suction well through the water inlet pipe...

Embodiment 2

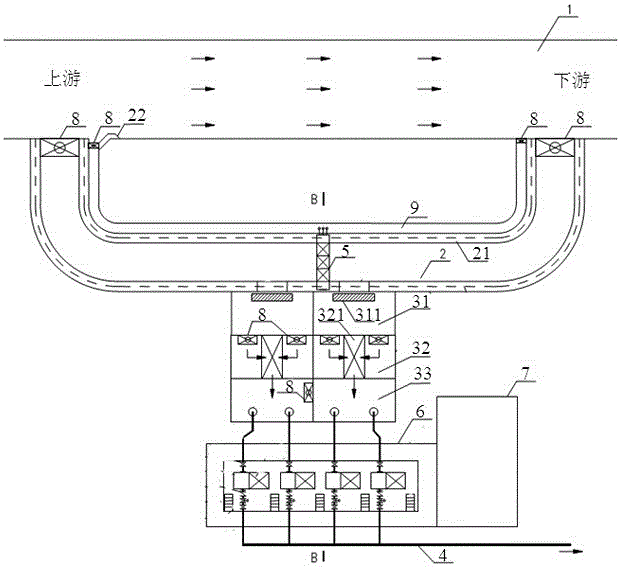

[0064] Such as image 3 , 4 As shown, this embodiment is suitable for the water intake water body 1 is relatively wide, and the water intake water body management department does not allow the water intake rectification area 2 to be set in the water body but allows the water intake pump room to be used under the situation of the water intake water body 1; in this embodiment, the described The water inlet rectification area 2 is arranged on the bank close to the water intake water body 1 side and is parallel to the water flow direction of the water intake water body 1; A partition gate 8 is set, and a mud discharge tank 9 is provided on one side of the water intake body 1, and a partition gate 8 is respectively provided at both ends of the mud discharge tank 9; the structure of the water intake well, the water intake pump room 6 and the power distribution room 7 is the same as in Embodiment 1 Same, no more details.

[0065] The form and operation mode of the flushing and suct...

Embodiment 3

[0067] Such as Figure 4 , 5 As shown, this embodiment is applicable to the water intake water body 1 is narrow, the water intake water body management department does not allow the water intake rectification area 2 to be set in the water body and the water intake pump room is not allowed to be used under the situation of the water intake water body 1; In this embodiment, a water inlet rectification area 2 is set on the bank near the water intake water body 1 side. One end of the mud discharge tank 9 is connected with the intake water body 1 and a partition gate 8 is set, and the other end of the water intake rectification area 2 is connected with the water absorption well; The front chamber 31 of the water suction well is transformed into a transitional form of the connecting area, specifically: partition walls 21 are arranged on both sides of the front chamber 31, and a grille 311 is arranged at the water inlet end and connected with the water inlet rectification area 2 at ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com