Mining method for deformed coal coalbed methane for V-shaped well bottom plate auxiliary layer

A technology for auxiliary layer and tectonic coal, which is applied in the fields of mining fluids, drilling equipment and methods, mining equipment, etc., can solve the problems of poor fracturing effect, pollution, and low production of coalbed methane in tectonic coal, so as to improve production and fracturing. Good effect, the effect of controlling large reserves in a single well

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

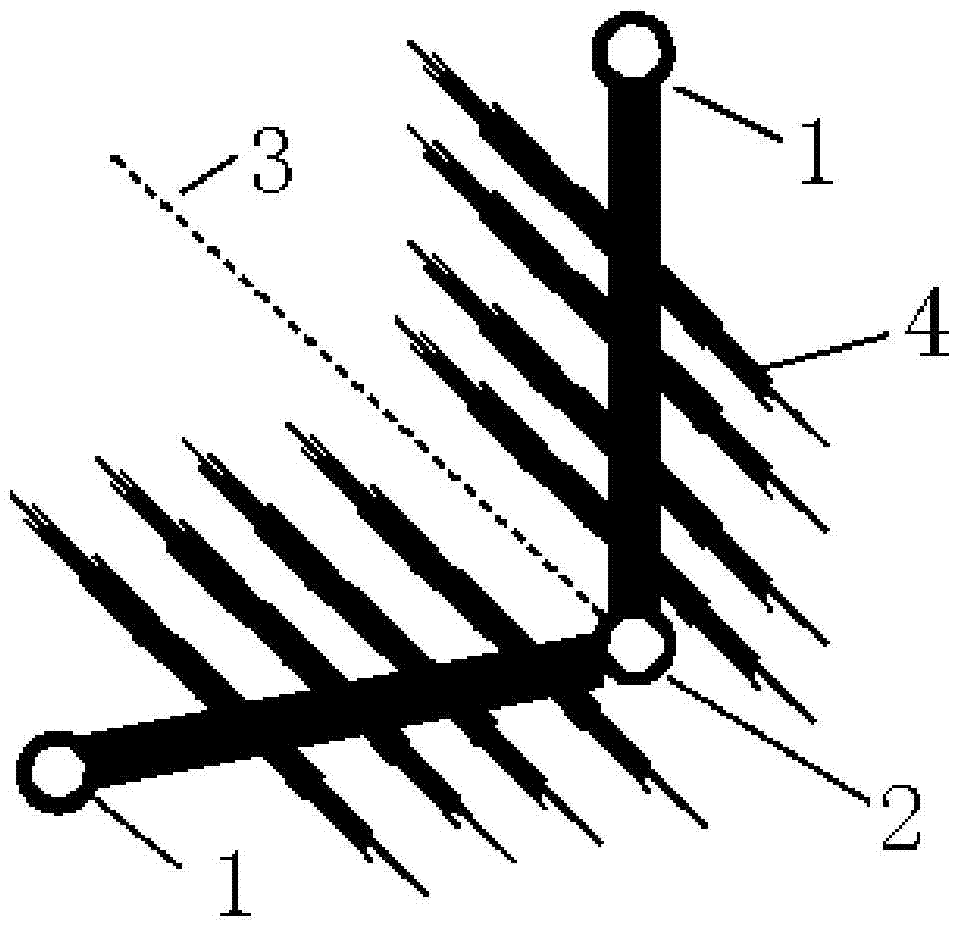

[0014] Such as figure 1 Shown, a kind of method for mining structural coal seam gas in the auxiliary layer of V-shaped well floor, the method steps are as follows: 1. Well location deployment: For structural coal seam gas fields, implement V-shaped wells, that is, the far ends of two horizontal wells 1 and the same One vertical well 2 is docked, and two horizontal wells 1 are arranged in the brittle sandstone or siltstone brittle rock formation 8-15m below the coal bottom; the positional relationship of the three wells on the plane: the positional relationship of the three wells on the plane should take into account the overall structure Due to factors such as height, ground stress, etc., in order to facilitate drainage, the vertical well 2 is arranged at a low position, and the angle between the well axes of the two horizontal wells 1 is between 90-180°, and the bisector of the angle is as close as possible to the maximum principal stress direction 3 Parallel in order to maxi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com