Horizontal well mechanical layering and hydraulic jet fracture acidizing compound technique pipe

A technology of hydraulic jetting, fracturing and acidizing, applied in wellbore/well components, production fluids, earth-moving drilling, etc., can solve the problems of large nozzle wear, limited life, large casing damage, etc., achieving good effect and adaptability strong effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

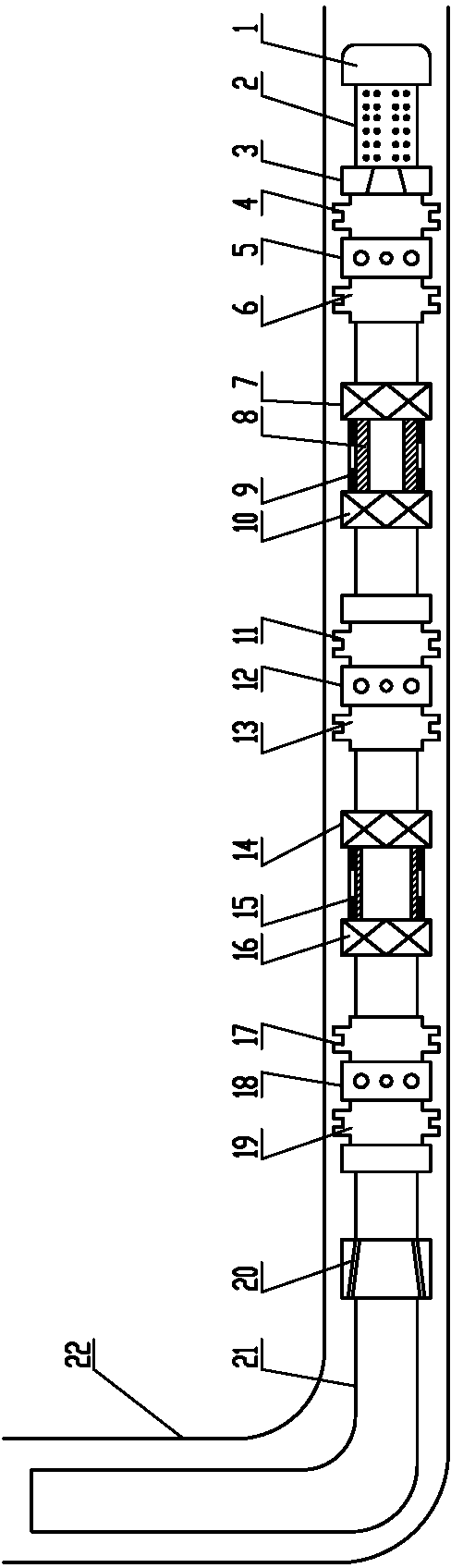

[0028] Such as figure 1 Shown is the horizontal well mechanical stratification and hydrojet fracturing and acidizing composite process string of the present invention. The process string in this embodiment takes five sections as an example, specifically including the casing 22 extending from the wellhead to the downhole horizontal well section and The oil pipe 21, the horizontal well section at the lower end of the oil pipe 21 is connected with a safety joint 23, and the oil pipe below the safety joint 20 is sequentially connected with a first-stage hydraulic injector 5, a first-stage sliding sleeve sand blaster 9, The second-stage hydro-ejector 12, the second-stage sliding sleeve sand blaster 15 and the third-stage hydro-ejector. A centralizer 4 and a centralizer 6 are respectively arranged on the oil pipes at both ends of the first hydraulic injector 5, a K344 packer 7 and a K344 packer 10 are respectively connected to the oil pipes at both ends of the first-stage sliding sl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com