Method for detecting active diffusion radius of covered rock separation grouting filling slurry

A technology of diffusion radius and isolation grouting, which is applied in the fields of filling, measurement, earthwork drilling, etc., can solve problems such as unpublished detection methods, and achieve the effect of protecting safety and improving effectiveness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Embodiment 1, take a certain working face as an example:

[0029] 1. Arrange ground grouting drilling.

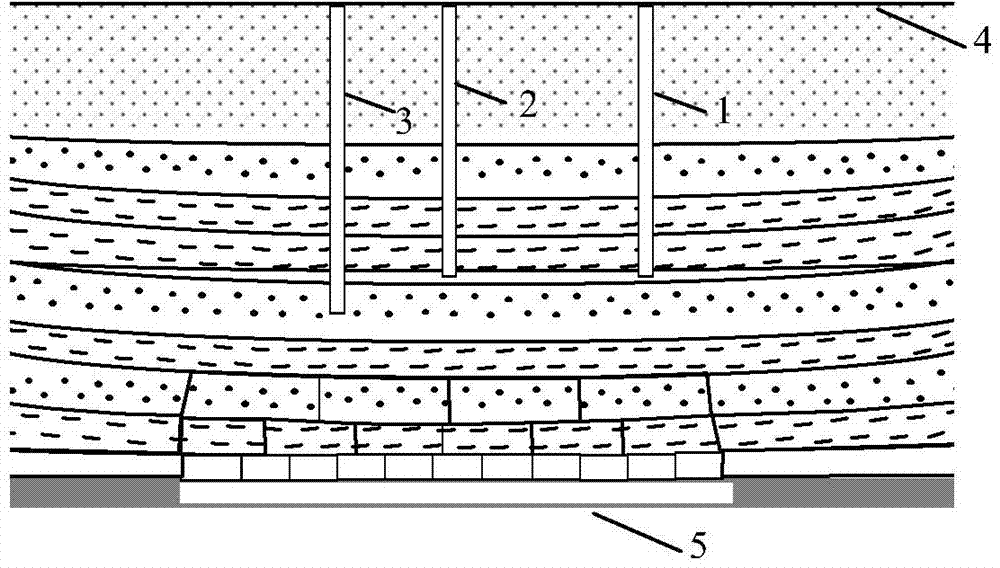

[0030] a. Construct grouting drilling 1 in the direction of the coal seam on the ground surface 4 60m away from the cutting hole in the middle of the coal mining face 5. There is only one drilling hole in the group, and the depth of the final hole is located at a position 40 times the mining height above the coal seam, that is 120m.

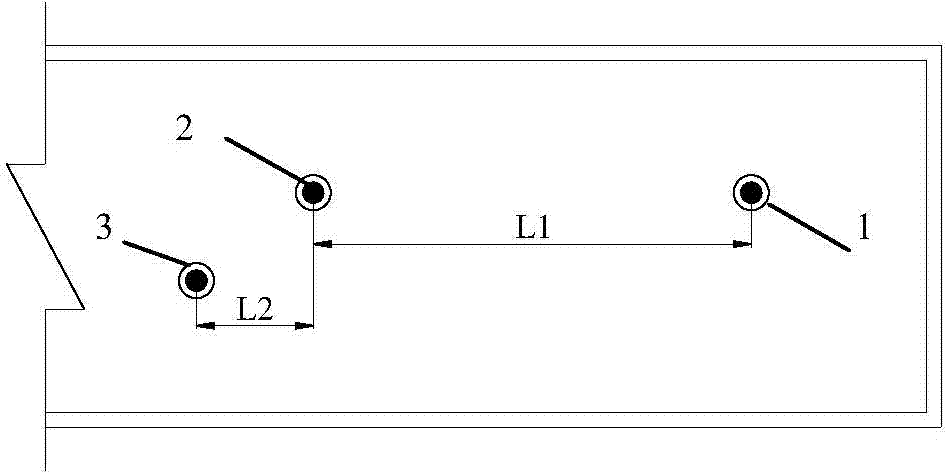

[0031] b. Set the distance between the second group of grouting holes and the grouting hole 1 as L1, and set the horizontal distance between the main grouting hole 3 and the auxiliary grouting hole 2 as L2;

[0032] c. Construct the auxiliary grouting borehole 2 in the direction of the coal seam at a distance of 100m from the grouting borehole 1 on the surface 4, and construct the main grouting borehole 3 at the horizontal distance between the surface 4 and the auxiliary grouting borehole 2 at a distance of 50m. The depth is 30m below...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com