Reinforced type aligning roller bearing rotary repairing tool and method

A self-aligning roller bearing, enhanced technology, applied in the direction of bearing components, shafts and bearings, mechanical equipment, etc., can solve the problems of difficult to guarantee repair consistency, large amount of manual labor, poor repair effect, etc., to improve repair efficiency , easy production and high repair efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

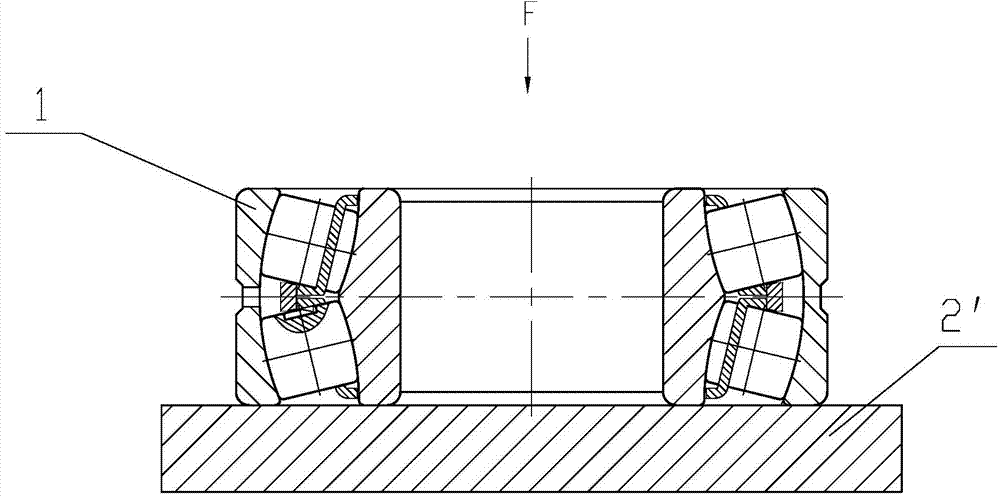

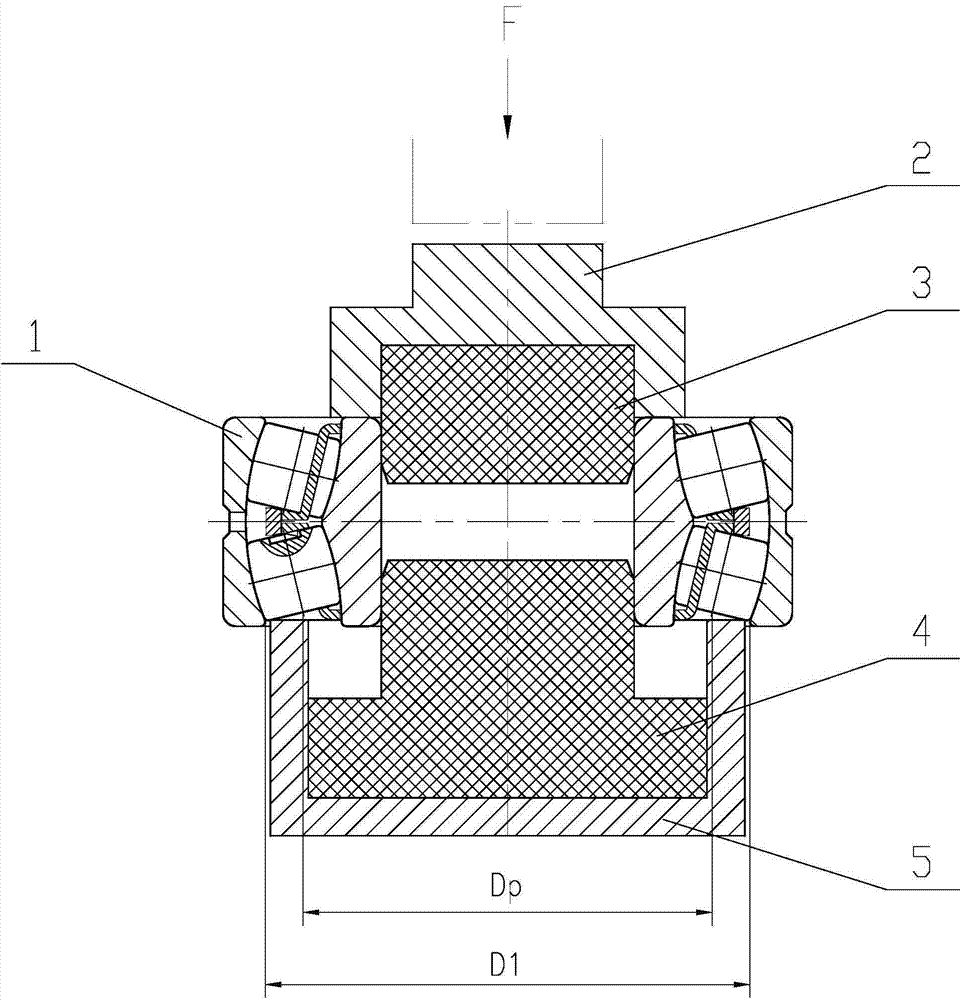

[0032] Embodiment one, as attached figure 2 to attach Figure 7 Shown: the reinforced spherical roller bearing rotary repair tool of the present invention includes an upper die 2, an upper guide post 3, a lower guide post 4, a lower support die 5, and a set screw 6.

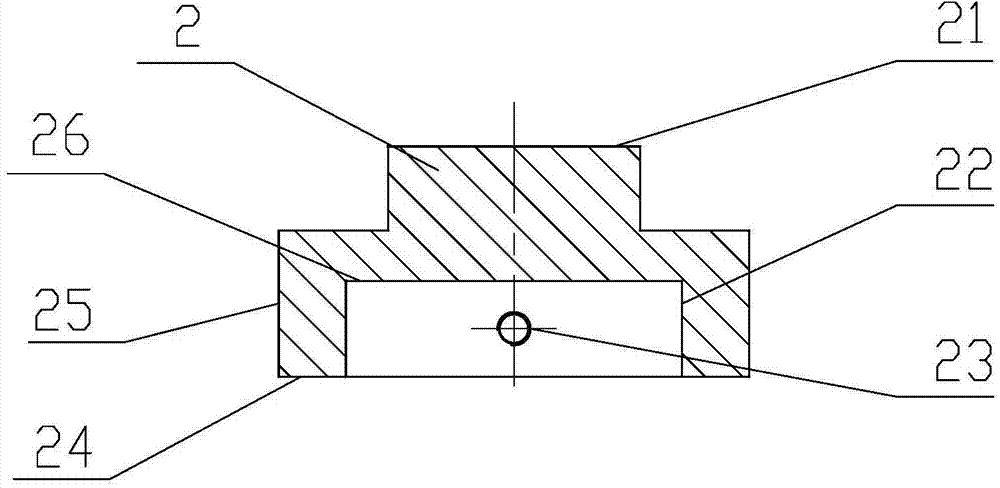

[0033] The upper die 2 is in the shape of a stepped shaft, such as image 3 According to the different diameters, it is divided into two parts: the small diameter cylinder and the large diameter cylinder in the upper part. The small diameter cylinder part is a solid structure, which is the part of the force transmission. The smaller force application area can be conducive to the uniform force. , a first blind hole 22 toward the inside of the entity is provided on the large-diameter end face 24 of the upper die at one end of the large-diameter cylinder away from the small-diameter cylinder, such as image 3 , the diameter (inner diameter) of the first blind hole 22 is the same as the inner diameter of the reinf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com