Two-dimensional strain flexible high temperature fiber grating sensor based on braided structure

A fiber grating and two-dimensional strain technology, applied in the direction of instruments, optical devices, measuring devices, etc., can solve the problems that strain sensors cannot be applied and two-dimensional strain detection cannot be performed, so as to facilitate the formation of distributed sensor networks and increase The effect of measuring ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

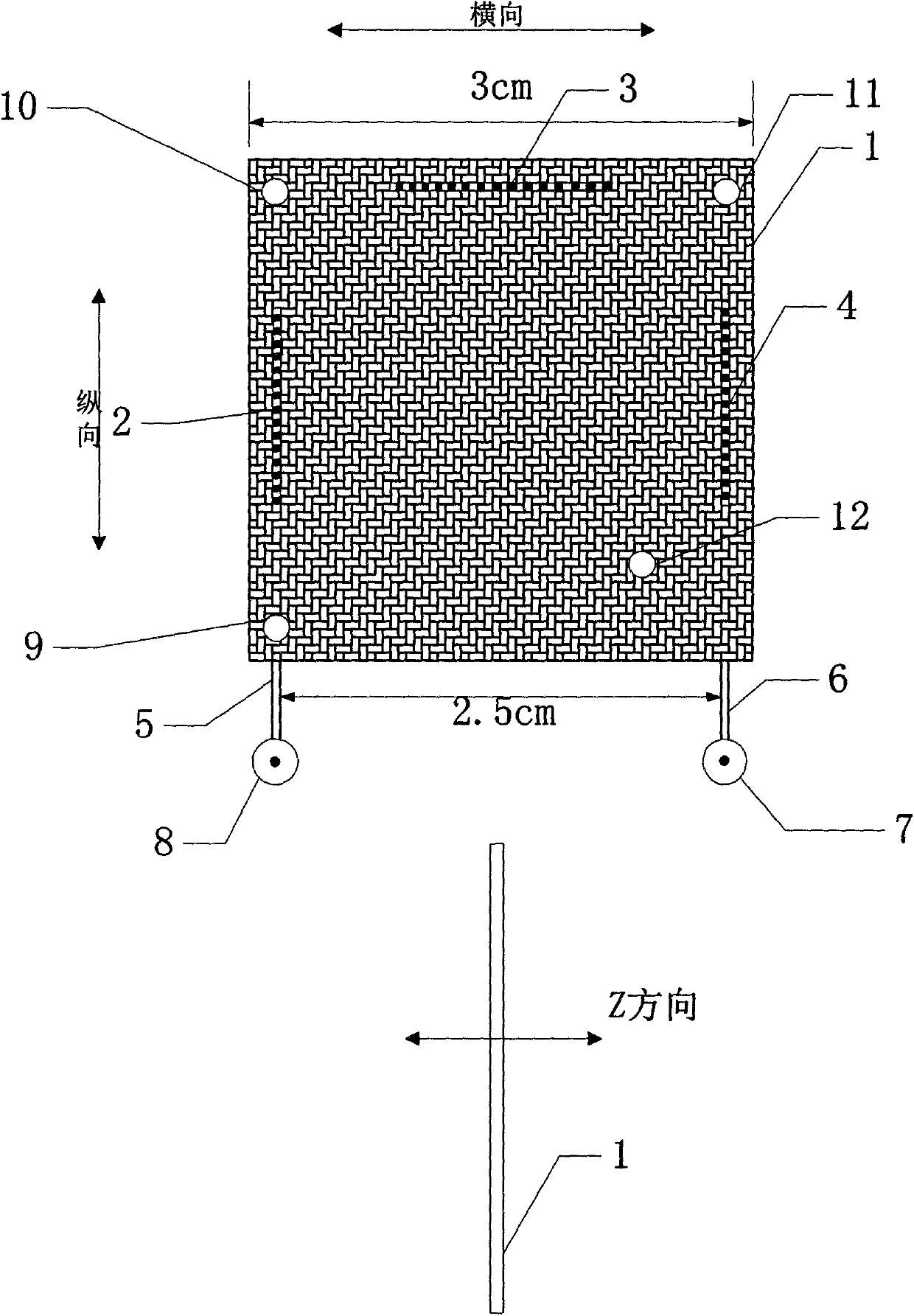

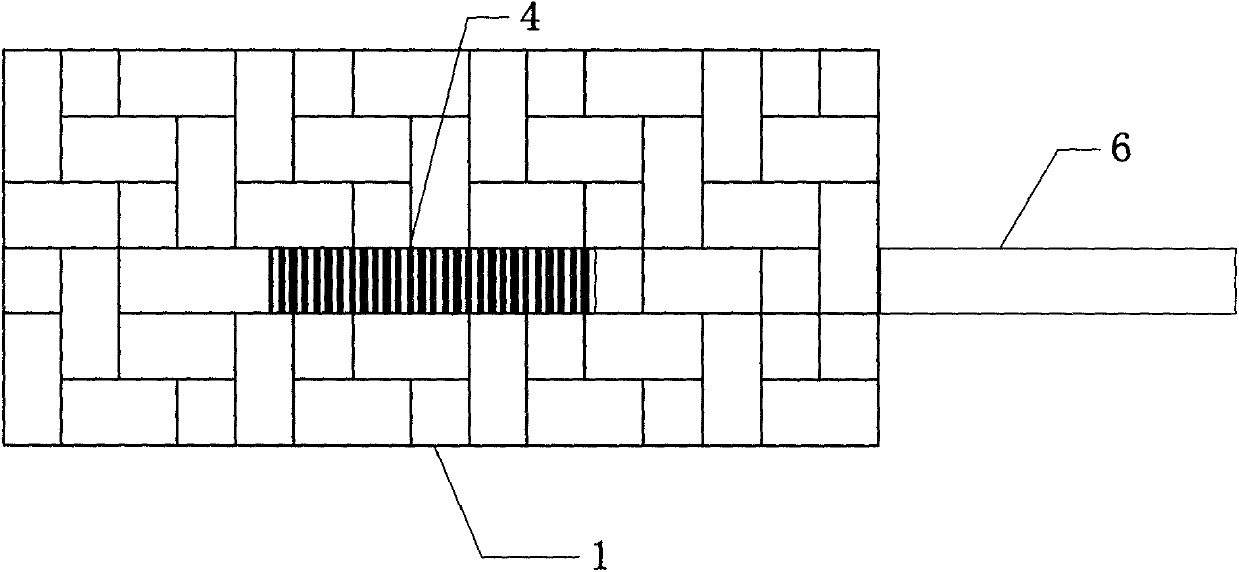

[0020] The following will be combined with figure 2 to attach Figure 4 The present invention is described in further detail with the specific embodiment:

[0021] Two-dimensional strain-flexible high-temperature fiber grating sensors based on braided structures such as figure 2 As shown, it includes a substrate 1 woven by T300 carbon fiber, which is square and has good flexibility of woven cloth, in which 3 LPFGs are woven, namely LPFG1 2, LPFG2 3, LPFG3 4, and the optical fiber is between the three connections, the eigenwavelengths also vary. Among them, LPFG1 2 is longitudinally woven in the base material, and its intrinsic wavelength is only affected by longitudinal strain, so that the longitudinal strain on the surface of high-temperature components can be measured; LPFG2 3 is transversely woven in the base material, when there is a strain change in the transverse direction, its intrinsic wavelength The wavelength will also change accordingly. According to this chang...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com