Bridge cantilevered casting hanging basket controllable equivalent pre-load testing method

A technology of preloading and test methods, which is applied in bridges, bridge construction, erection/assembly of bridges, etc., can solve the problems of material waste cost, long pressure test period, and inability to reflect the settlement as a whole, and shorten the test time. The time and data are real and reliable, and the effect of load equivalent controllability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

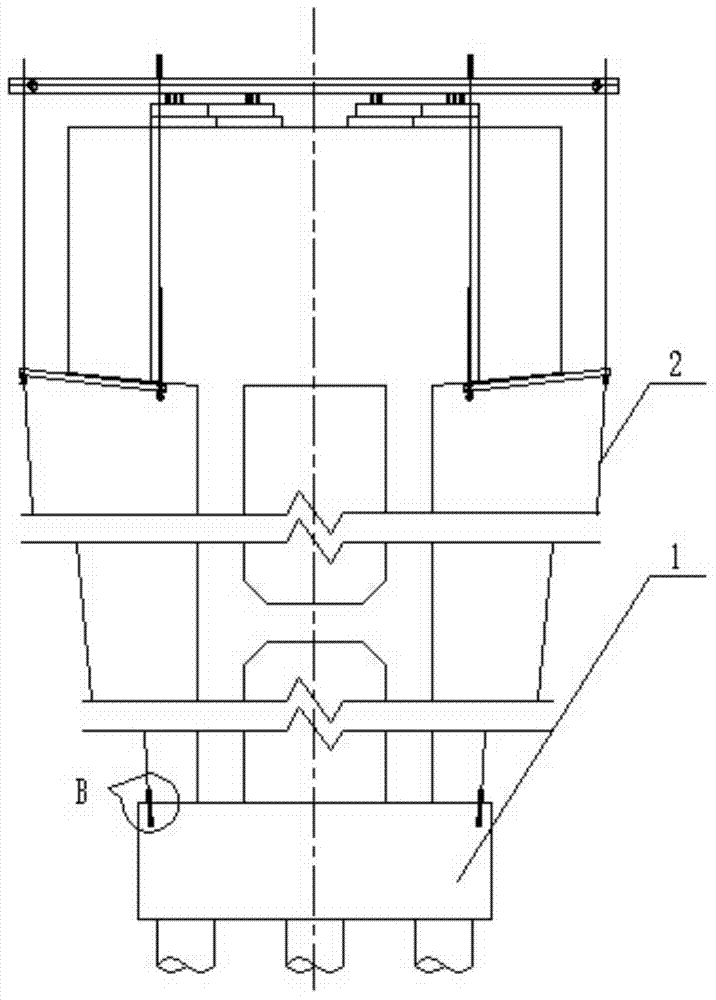

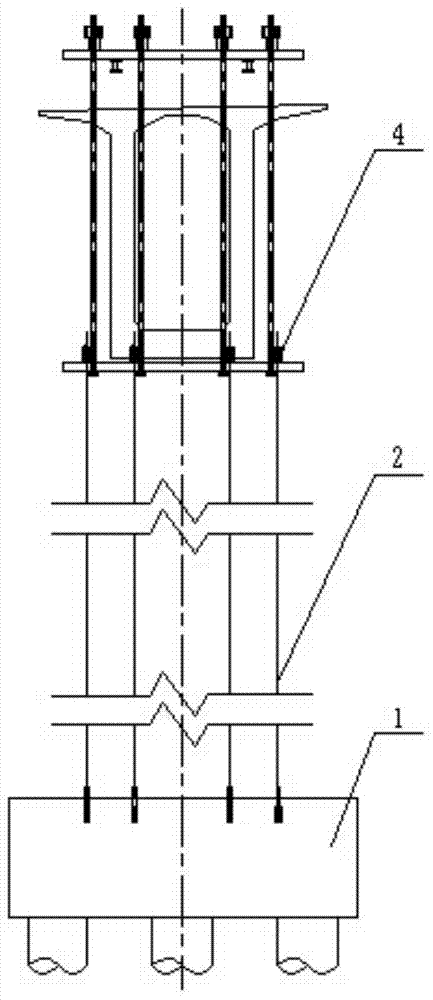

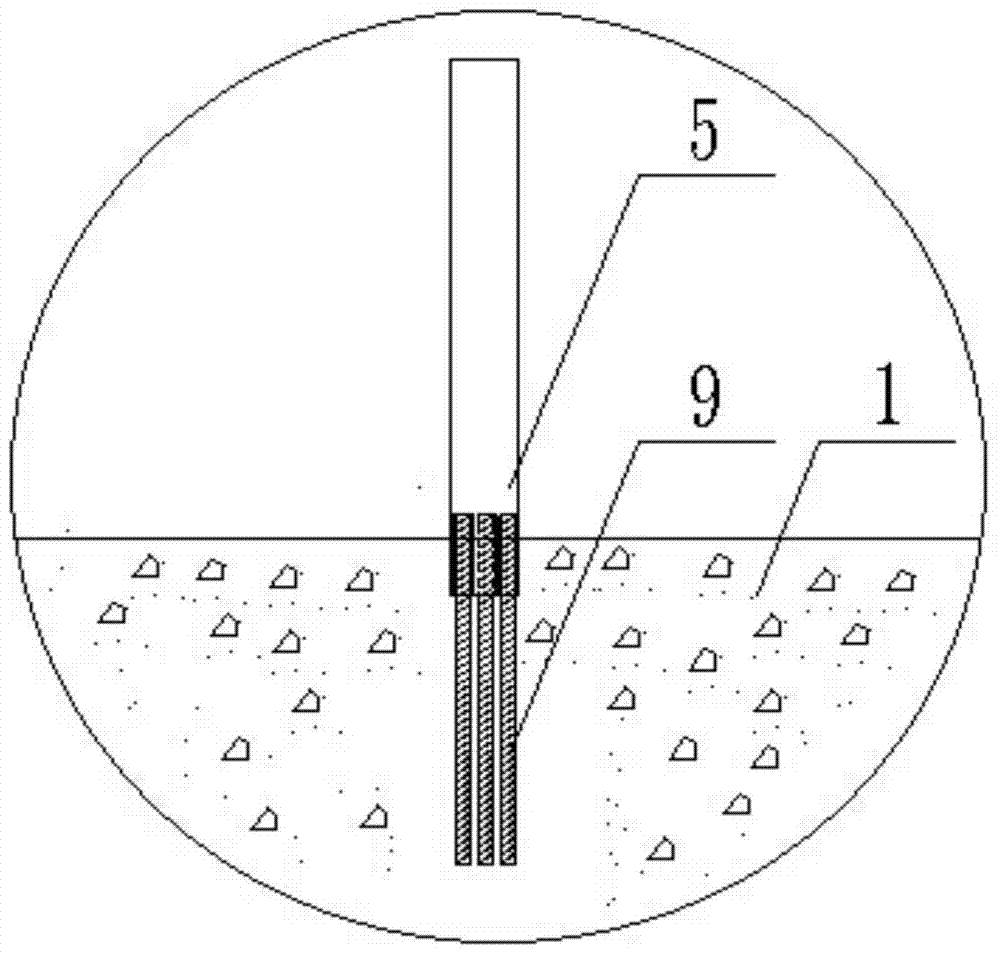

[0031] Such as figure 1 , figure 2 , image 3 , Figure 4 and Figure 5 As shown, this embodiment includes components such as bridge cap 1, steel strand 2, through-hole jack 4, embedded steel plate 5, baffle plate 6, anchor head 7, stiffening plate 8, and rebar 9. The example contains the following steps:

[0032] 1) First, four anchoring devices are arranged symmetrically along the longitudinal direction of the bridge at both ends of the top surface of the bridge cap 1. Each anchoring device includes 6 threaded steel bars and two pre-embedded steel plates 5, of which four threaded steel bars The steel bars are symmetrically arranged on the outside of the two pre-embedded steel plates, and the other two rebar bars are symmetrically arranged on the inside of the two pre-embedded steel plates. The lower ends of the rebar bars are pre-embedded in the bridg...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com