Sealed stator

A technology of sealing stators and stators, which is applied in the manufacture of stator/rotor bodies, winding insulation shapes/styles/structures, magnetic circuit shapes/styles/structures, etc., can solve problems such as long flow paths and shortened sealing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] In order to make the above-mentioned and other objects, features and advantages of the present invention more comprehensible, the preferred embodiments of the present invention are specifically cited below, together with the accompanying drawings, as follows:

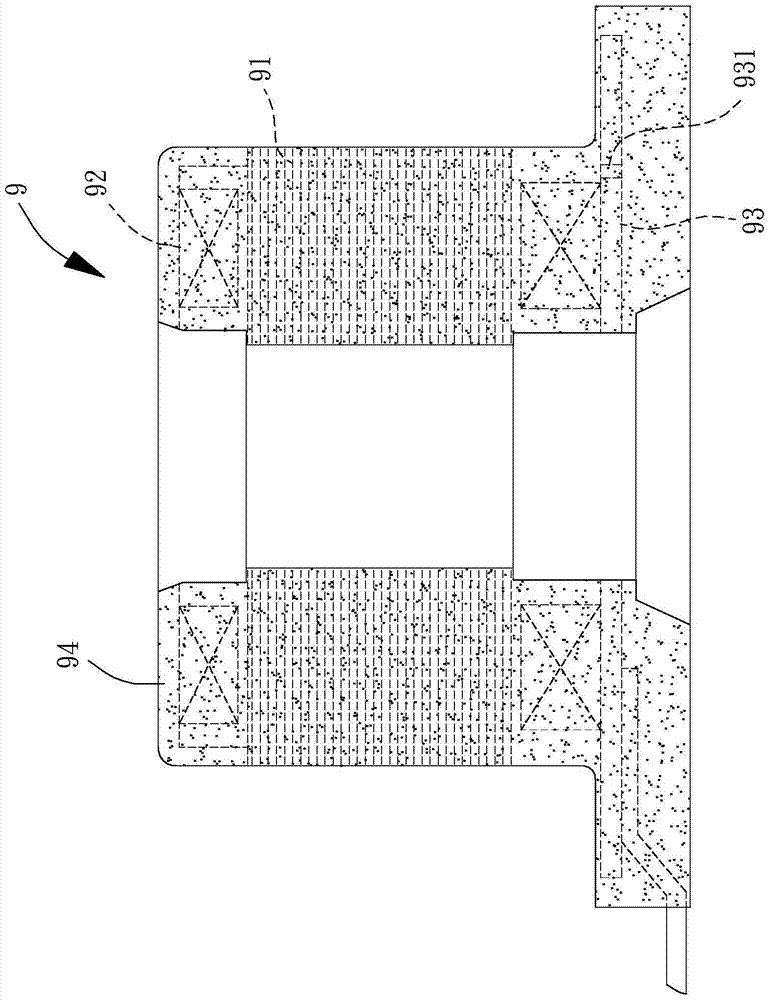

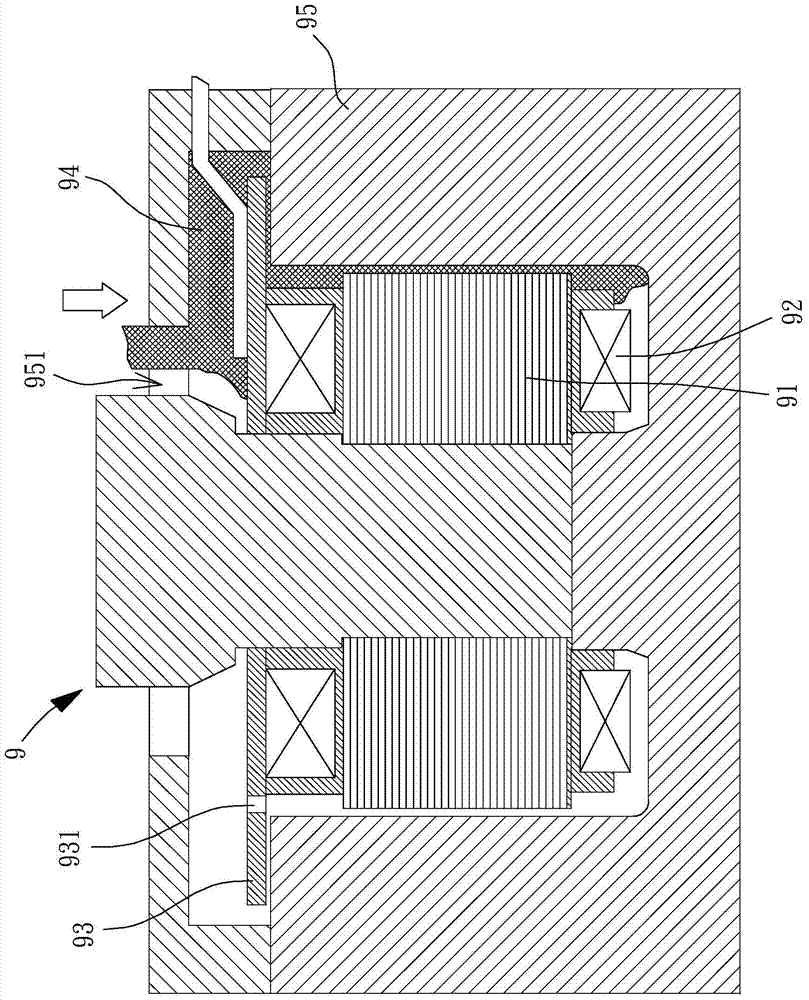

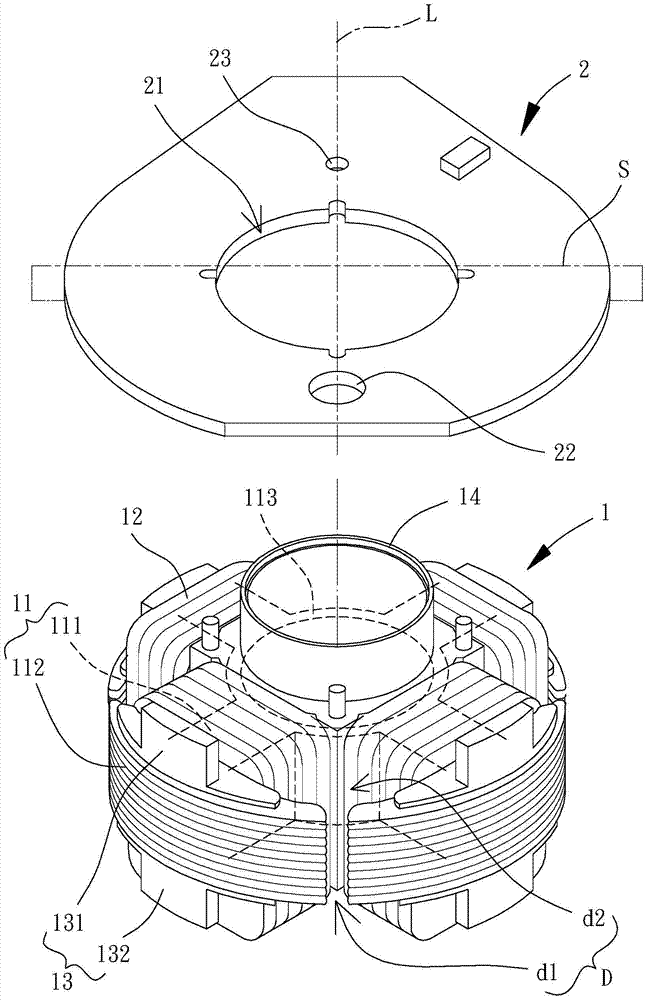

[0040] Please refer to image 3 and 4 As shown, the sealant stator of the present invention at least includes a stator assembly 1 , a circuit board 2 and sealant 3 . The circuit board 2 is disposed at one end of the stator set 1 ; the sealant 3 covers the stator set 1 and the circuit board 2 .

[0041] The above-mentioned stator assembly 1 at least includes an iron core 11 and a coil 12 . Please refer to Figure 5 As shown, the iron core 11 is provided with several pole arms 111, and the several pole arms 111 are arranged radially with a distance from each other. One end of the several pole arms 111 is respectively provided with a magnetic conduction part 112, any of which There is a first gap d1 between the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com