Intelligent LED drive control circuit

A LED drive and control circuit technology, which is applied to the layout of electric lamp circuits, electric light sources, lighting devices, etc., can solve the problems of unable to adjust the output current and fixed output current, and achieve stable and reliable working performance, small size, and low cost. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

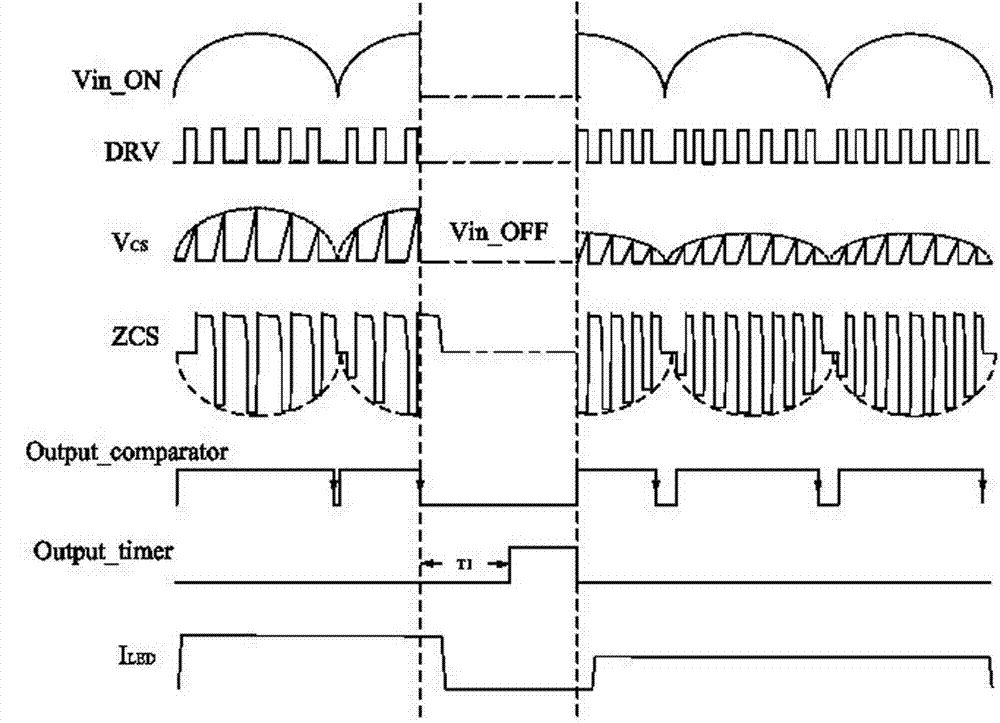

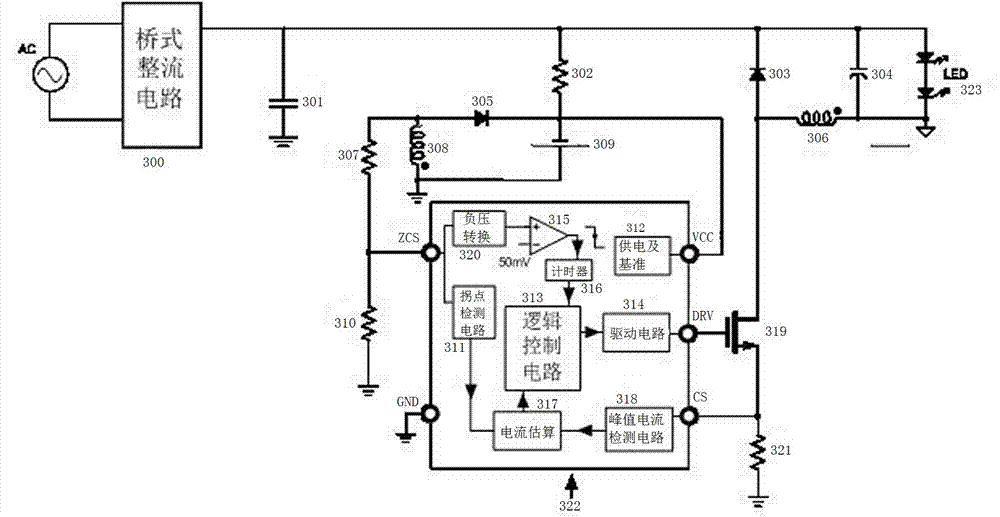

[0015] Such as figure 1 An intelligent LED drive control circuit is shown, which includes a bridge rectifier circuit 300 and an LED drive control circuit 322. The bridge rectifier circuit 300 is connected in parallel with a high-voltage filter capacitor 301, a first resistor 302, and an LED drive circuit 323, wherein the The first resistor 302 is connected in series with the second resistor 307, the second resistor 307 is grounded through the third resistor 310, the second resistor 307 and the third resistor 310 are connected to the LED drive control circuit 322, and the LED drive The control circuit 322 is connected to the gate of the power transistor 319 , and the source of the power transistor 319 is grounded through the fourth resistor 321 . The bridge rectifier circuit 300 is connected in parallel with the energy storage capacitor 304 .

[0016] The LED drive control circuit 322 includes a peak current detection circuit 318, a current estimation circuit 317, a logic cont...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com