Method for removing inorganic arsenic in kelp

A technology of inorganic arsenic and kelp, applied in the fields of application, food preparation, food science, etc., can solve the problem of excessive inorganic arsenic in kelp, achieve the effects of ensuring food safety, simple operation, and improving removal rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

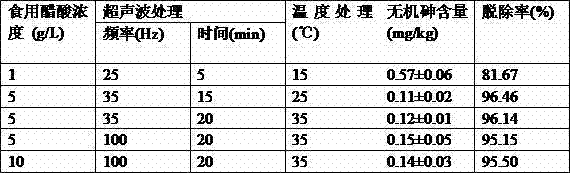

Embodiment 1

[0012] A method for removing inorganic arsenic from kelp, which comprises the following steps in turn: ① soak the dried kelp in ultrapure water for 6 hours, and then rinse it with ultrapure water for 3-5 times; ② put the kelp treated in the previous step into Ultrasonic treatment was carried out in an edible acetic acid solution with a concentration of 1g / L, the ultrasonic frequency was set at 25kHz, the treatment time was 5min, and the temperature of the edible acetic acid solution was 15°C; and dry.

Embodiment 2

[0014] A method for removing inorganic arsenic from kelp, which comprises the following steps in turn: ① soak the dried kelp in ultrapure water for 6 hours, and then rinse it with ultrapure water for 3-5 times; ② put the kelp treated in the previous step into Ultrasonic treatment was carried out in an edible acetic acid solution with a concentration of 5g / L, the ultrasonic frequency was set to 35kHz, the treatment time was 15min, and the temperature of the edible acetic acid solution was 25°C; and dry.

Embodiment 3

[0016] A method for removing inorganic arsenic from kelp, which comprises the following steps in turn: ① soak the dried kelp in ultrapure water for 6 hours, and then rinse it with ultrapure water for 3-5 times; ② put the kelp treated in the previous step into Ultrasonic treatment was carried out in an edible acetic acid solution with a concentration of 5g / L, the ultrasonic frequency was set at 35kHz, the treatment time was 20min, and the temperature of the edible acetic acid solution was 35°C; and dry.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com