A kind of LED glue and powder precision automatic batching equipment and batching method thereof

An automatic batching and precision technology, which is applied in the field of precision instruments, can solve the problems of powder proportion fluctuation, batching quality cannot be well guaranteed, poor reliability and repeatability, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

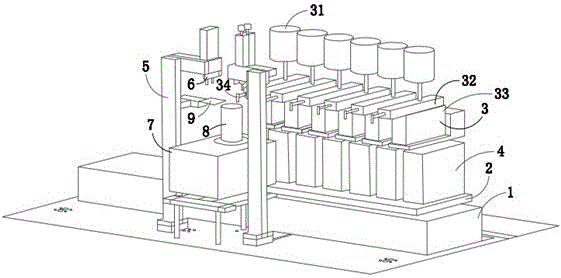

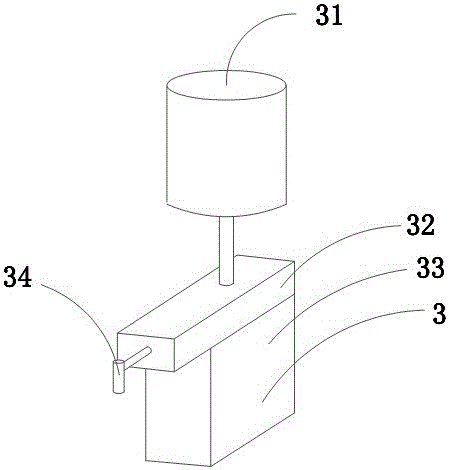

[0049] Embodiment 1: as Figure 1 to Figure 4 As shown, a LED glue and powder precision automatic batching equipment, the equipment includes a cabinet 11 and an air compressor 10 connected to the cabinet 11 through a gas pipe, the cabinet 11 has two upper and lower layers, and the top is provided with a cover plate 12. It also includes an LED glue and powder feeding device located on the upper inner layer of the cabinet body 11. This device includes a precision weighing instrument 7, an LED powder feeding component placed on the front side of the precision weighing instrument 7, and a separate part of the precision weighing instrument 7. The LED glue feeding components on the left and right sides, the precision weighing instrument 7 is fixed horizontally on the feet; the LED powder feeding component includes a fixed base 1, a support plate 2 and a support plate fixed on the support plate stacked from bottom to top. A plurality of LED powder feeding devices 3 horizontally arran...

Embodiment 2

[0058] Embodiment 2: The present invention is a mobile feeding design, the precision weighing instrument 7 belongs to a static state, and the LED powder feeding device 3 moves along the left and right directions of the precision weighing instrument 7 to carry out feeding, but as not limiting the limitations of the present invention, The present invention also provides a ring-shaped turntable feeding design, that is, each LED powder feeding device 3 is arranged on the ring-shaped turntable 19, such as Figure 8 As shown, the middle part of the ring-shaped turntable 19 is a hollow area, and a precision weighing instrument 7 is set at any place in this hollow area, and it is only necessary to make the blanking elbow 34 on the LED powder feeding device 3 point to the direction of the batching cup 8 That is, the batching cup 8 is placed on the precision weighing instrument 7 .

Embodiment 3

[0059] Embodiment 3: a kind of LED glue and powder precision automatic batching method, this method is to realize by the PLC controller 14 with display screen installed on the above-mentioned equipment, this PLC controller 14 has touch display screen, this PLC control The device 14 is connected to the position in the cabinet groove by a movable bracket (such as Figure 11 As shown), the movable bracket is composed of the controller inner fixed head 141 welded on the controller and the controller outer fixed head 142 connected to the two side walls of the cabinet groove, which can be moved to the outside of the groove through the movable bracket, and The placement angle can be adjusted within 90 degrees. When the LED glue feeding device is feeding, the PLC controller 14 obtains the actual glue output amount of the LED glue and the ratio of the demand through the weight feedback information of the precision weighing instrument 7, and calculates the actual proportion of the LED p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com