Accumulator colloidal electrolyte and its assembling and gel-filling technology

A technology of lead-acid battery and colloidal electrolyte, which is applied in the direction of lead-acid battery, lead-acid battery construction, secondary battery manufacturing, etc. It can solve the problems of colloid hydration, battery leakage, battery heating, etc. Convenience and good colloidal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

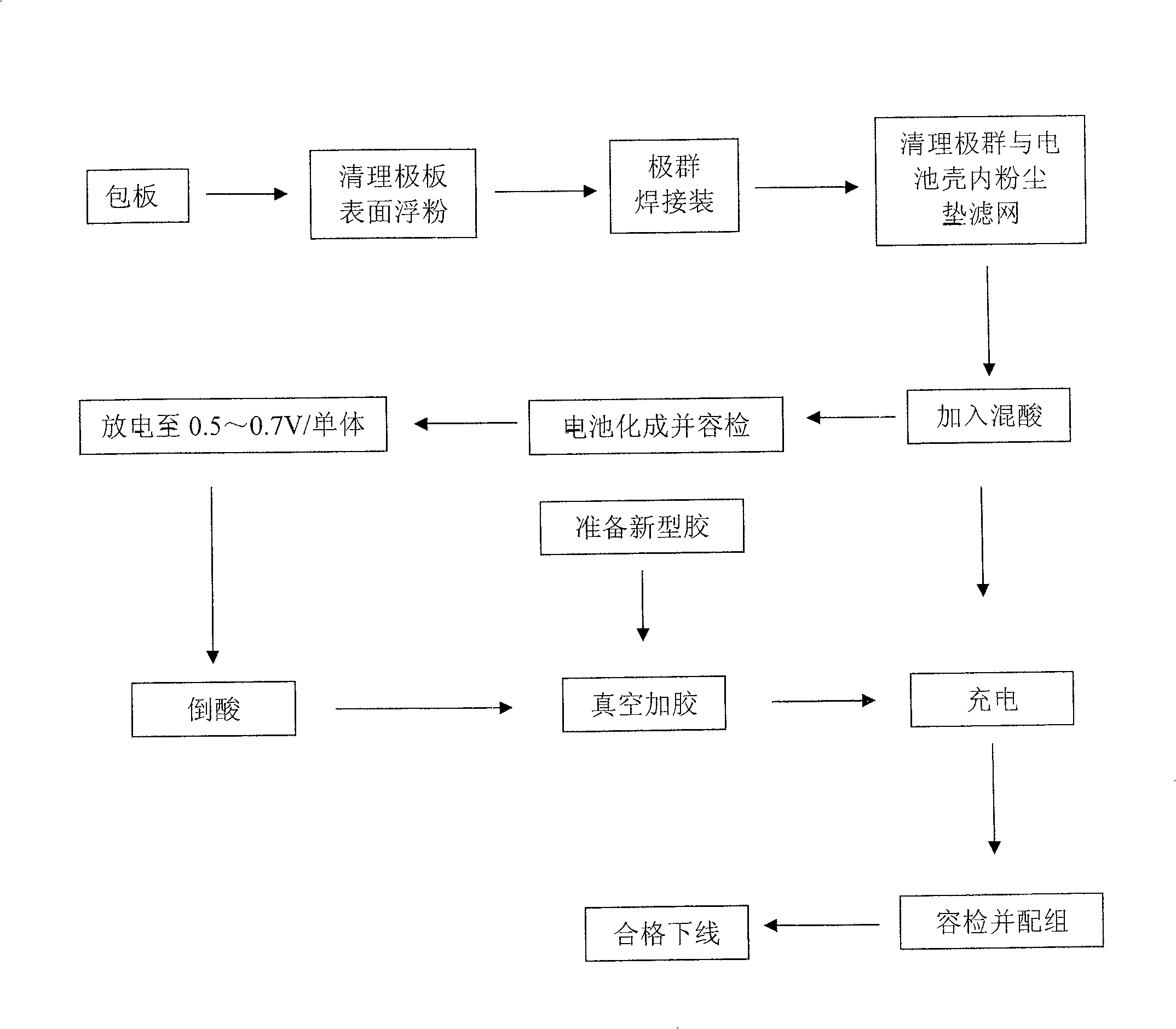

[0026] Taking the preparation of 2V200AH battery water glue as a model, adopt the assembling and adding glue process provided by the present invention ( figure 1 ), to make batteries and test their performance.

[0027] 1. Packing board;

[0028] 2. Remove the floating powder particles on the surface of the positive and negative plates; combine the positive and negative plates and separators into a single pole group; weld the single pole group and put it into the battery case to become a battery; use an air gun or a vacuum cleaner to clean the The dust in the battery case is blown or sucked out, and then a layer of plastic filter is spread on the bottom of the bus bar of the battery.

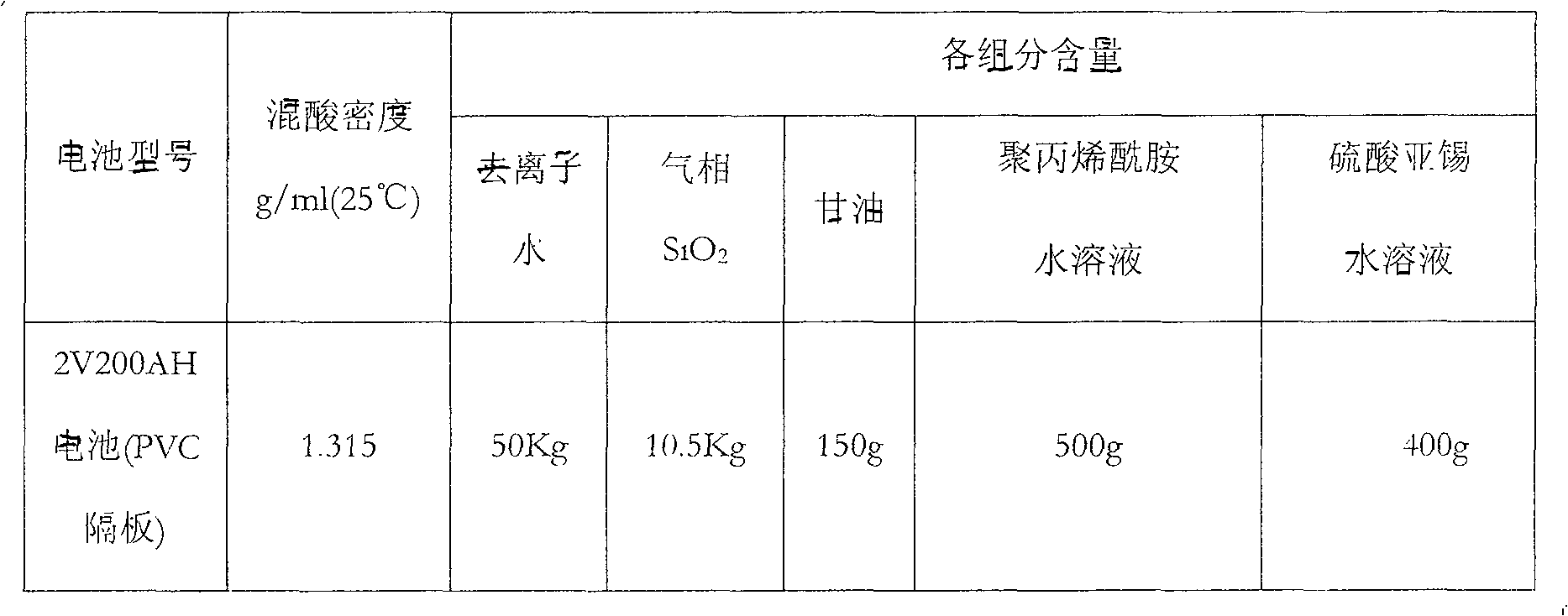

[0029] 3. Prepare the following materials as shown in Table 1:

[0030] Table 1

[0031]

[0032] Note: ① Mixed acid is sulfuric acid solution with 0.5% phosphoric acid by weight.

[0033] ②Gas phase SiO 2 For: the specific surface area is 200m 2 / g and 380m 2 / g gas phase SiO 2 Prepa...

Embodiment 2

[0063] Taking conventional 12V22AH batteries (nine) as sample batteries, the experiment was carried out by adopting the glue-adding process of the present invention.

[0064] experiment procedure:

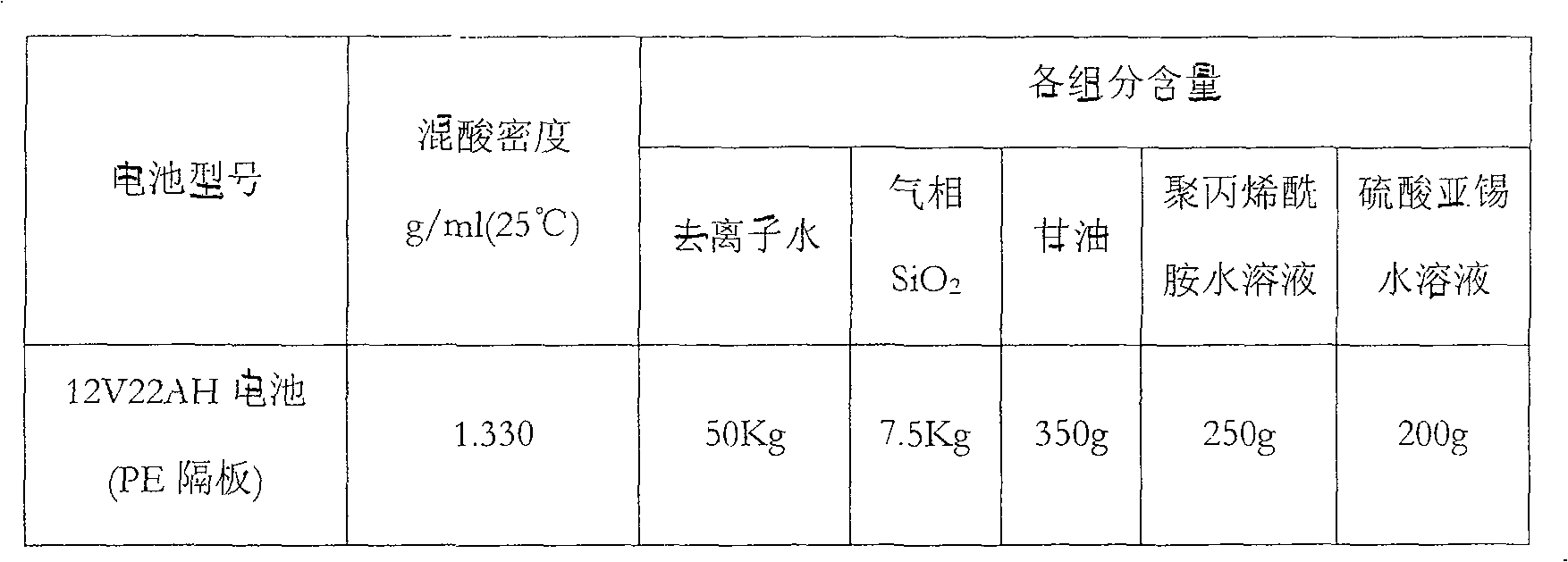

[0065] 1. Prepare the following materials as shown in Table 4:

[0066] Table 4

[0067]

[0068] Note: ① The mixed acid in the table is sulfuric acid solution with 0.5% phosphoric acid by weight.

[0069] ②Gas phase SiO 2 For: the specific surface area is 200m 2 / g and 380m 2 / g gas phase SiO 2 Prepared according to the weight ratio of 1:1.

[0070] ③ The polyacrylamide aqueous solution is a mixture of analytically pure polyacrylamide and deionized water in a weight ratio of 1:100.

[0071] ④ The aqueous solution of stannous sulfate is a suspension obtained by mixing and stirring stannous sulfate of analytically pure grade and deionized water at a weight ratio of 1:5. Shake well before use.

[0072] ⑤ After mixing, the specific gravity of the colloid is 1.06g / ml.

[00...

Embodiment 3

[0095] Experimental content: take a medium-density 12V100AH battery as a sample battery, and use the glue adding process of the present invention to conduct experiments.

[0096] experiment procedure:

[0097] 1. Prepare the following materials as shown in Table 8:

[0098] Table 8

[0099]

[0100] Note: ① The mixed acid in the table is sulfuric acid solution with 0.5% phosphoric acid by weight.

[0101] ②Gas phase SiO 2 For: the specific surface area is 200m 2 / g and 380m 2 / g gas phase SiO 2 Prepared according to the weight ratio of 1:1.

[0102] ③ The polyacrylamide aqueous solution is a mixed solution of analytically pure polyacrylamide and deionized water in a weight ratio of 0.75:100.

[0103] ④ The aqueous solution of stannous sulfate is a suspension obtained by mixing and stirring stannous sulfate of analytically pure grade and deionized water at a weight ratio of 1.5:10. Shake well before use.

[0104] ⑤ After mixing, the specific gravity of the glue is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com