Cutter loading system for numerical control cutter grinding machine

A tool grinder and tool technology, applied in the direction of manufacturing tools, grinding feed movement, other manufacturing equipment/tools, etc., can solve problems such as low efficiency, unstable quality of grinding tools, and restricting the efficiency of CNC grinding, so as to improve production Work efficiency, the effect of realizing CNC automatic production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The following descriptions are only preferred embodiments embodying the principles of the present invention, and do not therefore limit the protection scope of the present invention

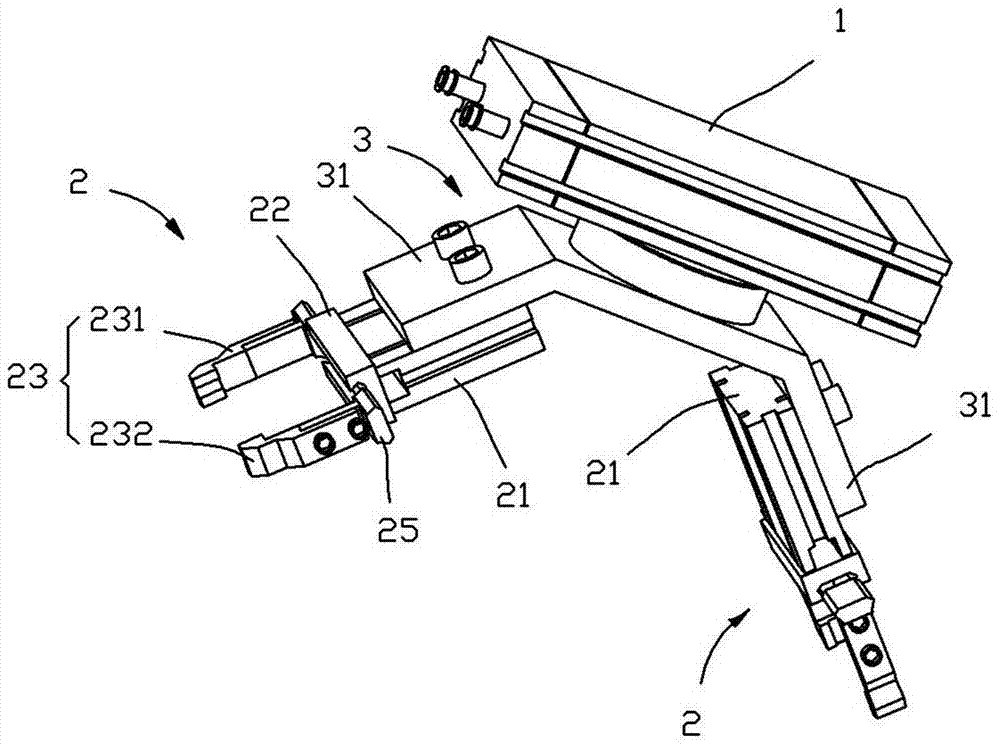

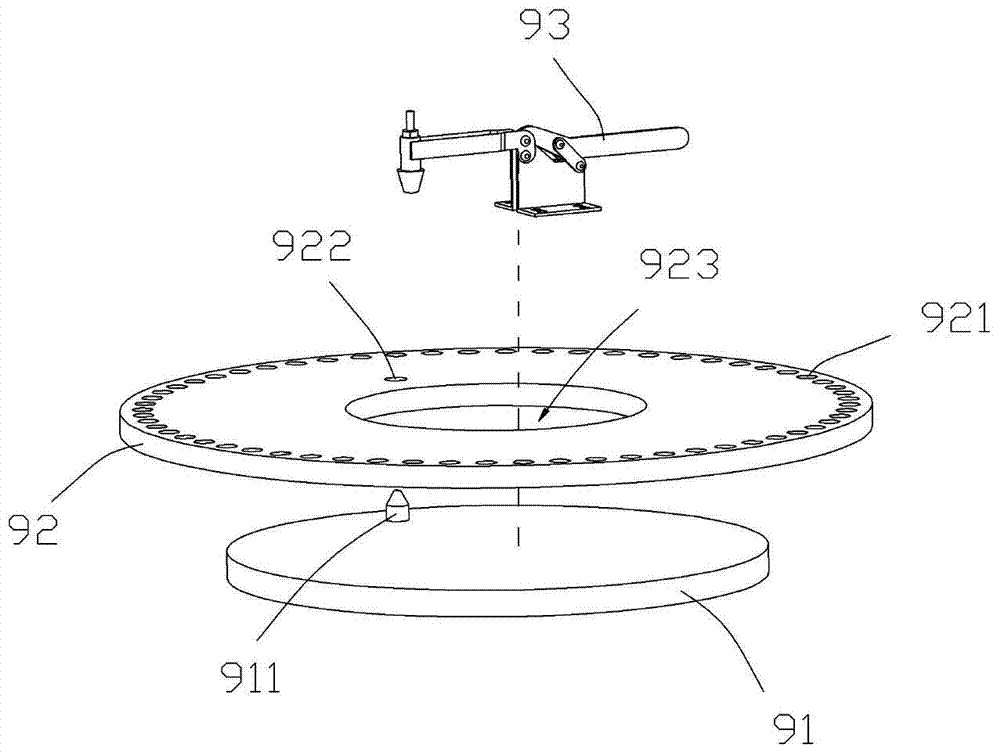

[0023] Such as Figures 1 to 2 Shown is an embodiment of the loading and unloading mechanism of the present invention, which includes a rotary cylinder 1, the mounting plate body 3 is fixed on the rotating part of the rotary cylinder (1), and the two ends of the mounting plate body 3 are bent and formed There are two bent plate parts 31, the two bent plate parts 31 form an included angle of 90°, and a tool clamping mechanism 2 is respectively installed on the two bent plate parts 31;

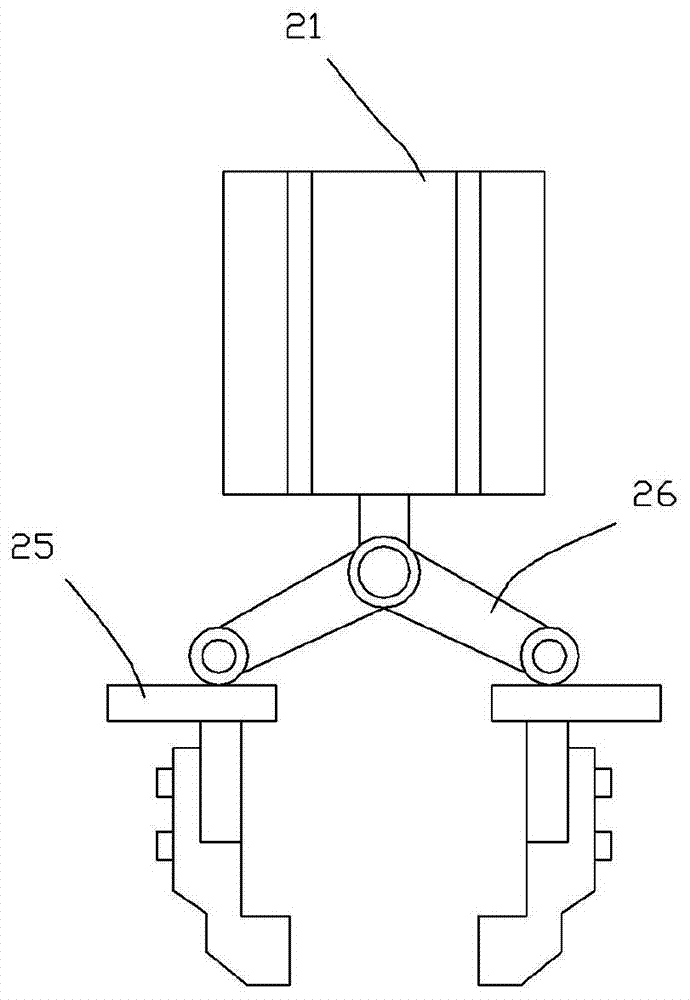

[0024] The structure of the tool clamping mechanism 2 includes a driving cylinder 21 and a guide rail component 22 . The clamp part 23 is movably mounted on the guide rail component 22 . The clamp part 23 is driven by the piston rod of the drive cylinder 21 .

[0025] In this embodiment, the clamp part 23 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com