Automobile central channel reinforcement structure

A central channel and reinforced structure technology, which is applied to the upper structure, upper structure sub-assembly, vehicle parts, etc., can solve the problems of increased cost, inability to achieve a strengthening effect, and inability to transmit loads, so as to facilitate installation and disassembly, reduce Casualties of small occupants, effects of improving side impact performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The specific implementation manner of the present invention will be described in further detail below by describing the embodiments with reference to the accompanying drawings.

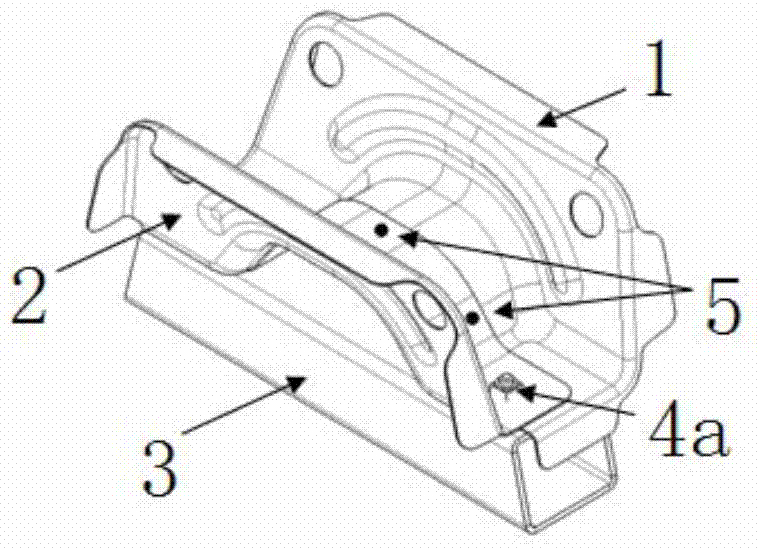

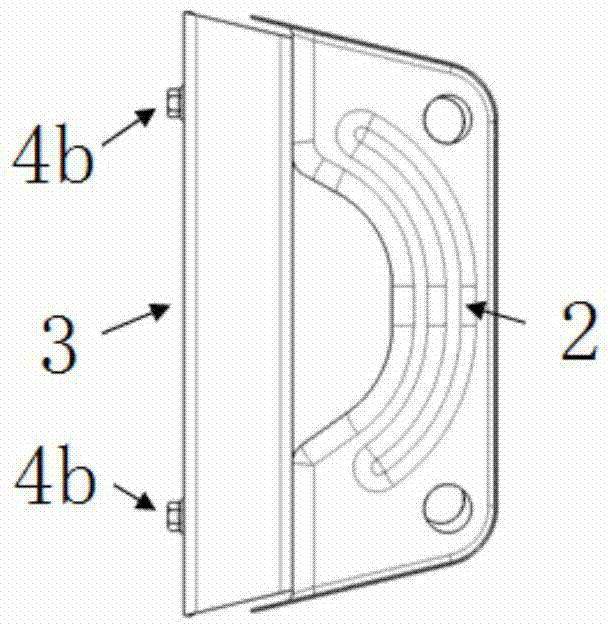

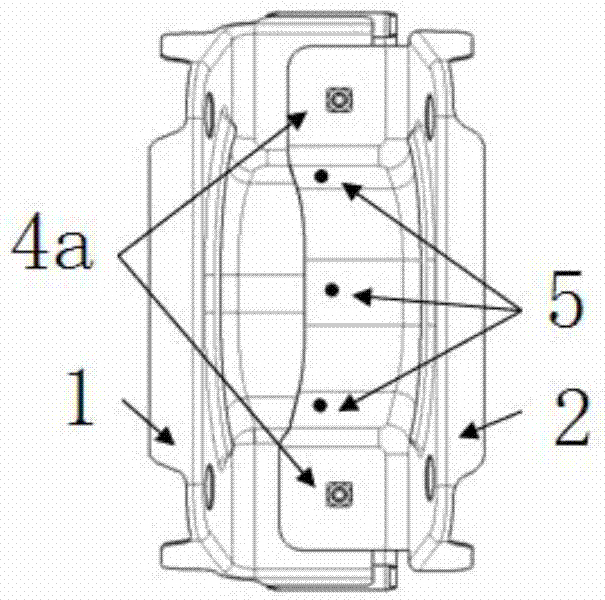

[0028] like Figure 1 to Figure 5 As shown, the reinforced structure of the central passage of the automobile is arranged under the central passage of the automobile. The reinforced structure includes a support and a supporting beam. The support includes a support I1 and a support II2. Both the support I1 and the support II2 include a side surface and a bottom surface , the side is provided with flanging to facilitate welding with the central channel body 6 .

[0029] The bottom surfaces of the support piece I1 and the support piece II1 are welded together through the welding spot 5 , the cross section of the support piece is a U-shaped structure, and the edge of the U-shaped structure of the support piece is provided with a flange welded with the central channel body 6 . Both the side surface...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com