Combustion-supporting fan linkage control system and method

A technology of linkage control system and combustion-supporting fan, applied in pump control, machine/engine, heat treatment process control, etc., can solve energy waste and other problems, achieve the effect of reducing workload, reducing waste of electric energy, and overcoming selection difficulties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

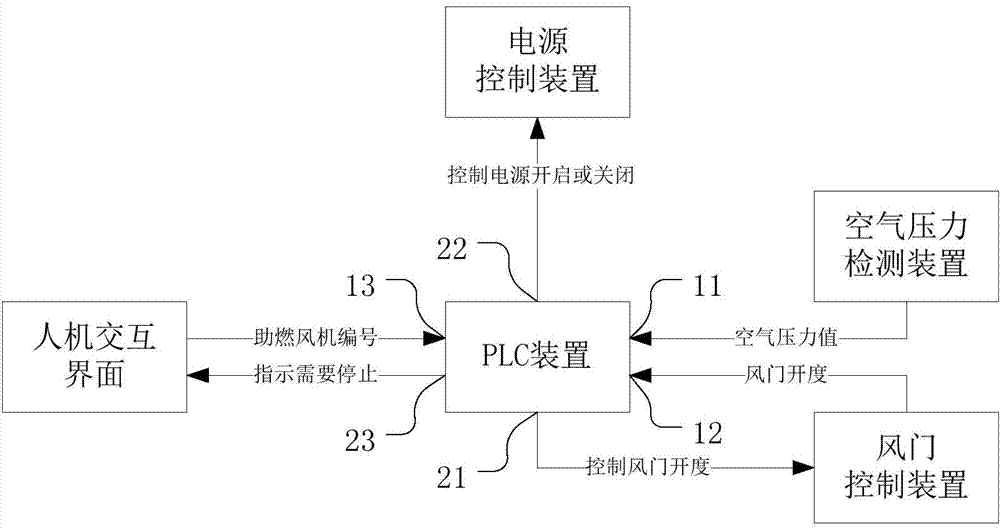

[0042] The combustion-supporting fan linkage control system and method of the present invention use a PLC device to automatically control the damper opening of the combustion-supporting fan, and automatically determine the optimal number of combustion-supporting fans currently needed to realize the linkage control of the combustion-supporting fan.

[0043] Specifically, refer to image 3 , is a structural schematic diagram of the combustion-supporting blower linkage control system of the present invention. The combustion-supporting fan linkage control system of the present invention includes an air pressure detection device, a damper control device, a power supply control device, a man-machine interface and a PLC device.

[0044] The air pressure detection device is arranged on the main pipe connecting the combustion-supporting fan, and its output port is communicatively connected with the first input port 11 of the PLC device. The air pressure value is output to the first in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com