Well point dewatering method and device

A technology of well-point dewatering and well-point pipes, which is applied in construction, infrastructure engineering, etc., can solve the problems of affecting construction, affecting water output, and high energy consumption in operation, so as to reduce failures and safety accidents and reduce the number of graded precipitation series , The effect of reducing construction risks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

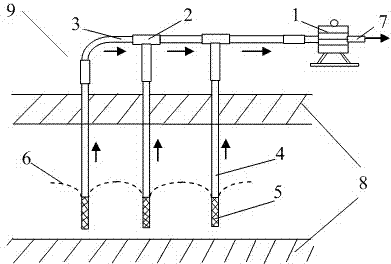

[0038] This embodiment provides a well point dewatering method, which uses the principle of light well point dewatering, combines the advantages of light well point dewatering and jet well point dewatering, and adopts an important innovative small-caliber plating method in the design of well point structure and pumping method. Zinc steel pipe well point precipitation has made a big breakthrough compared with the traditional precipitation method. A kind of well point precipitation method provided by the invention comprises:

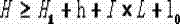

[0039] 1) Prepare well point pipes for dewatering according to project requirements. The well point pipes are small-diameter galvanized steel pipes with an outer diameter of less than 30 mm. It can be, but not limited to, the well point pipes are 25 mm in outer diameter and 2.5 mm in thickness. galvanized steel pipe, the length of the well point pipe is H:

[0040]

[0041] h 1 is the distance from the current ground to the bottom of the foundation pi...

Embodiment 2

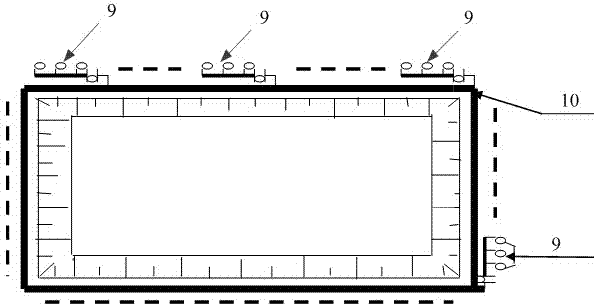

[0062] This embodiment provides a well point dewatering device, including a well point pipe for dewatering and pumping equipment, and the well point pipe is a small-diameter galvanized steel pipe with an outer diameter of less than 30 mm.

[0063] It is possible, but not limited to, that the well point pipe is a galvanized steel pipe with a diameter of 25 mm and a thickness of 2.5 mm, and the length of the well point pipe is H:

[0064]

[0065] h 1 is the distance from the current ground to the bottom of the foundation pit; h is the safe distance from the deepest excavation surface in the center of the foundation pit to the highest point of the precipitation curve; I×L is the product of the slope of the precipitation curve and the distance from the well point to the short side of the foundation pit center; It is the length of the filter pipe.

[0066] Several well point pipes are connected in parallel and connected to a single-phase self-priming pump to form a well point...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com