A solid rocket motor nozzle assembly connection sealing structure

A technology for engine nozzles and solid rockets, which is applied to rocket engine devices, machines/engines, mechanical equipment, etc. It can solve problems such as temperature shock resistance, high impact, and limited structural space, and achieve high connection strength and connection reliability. High, simple processing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

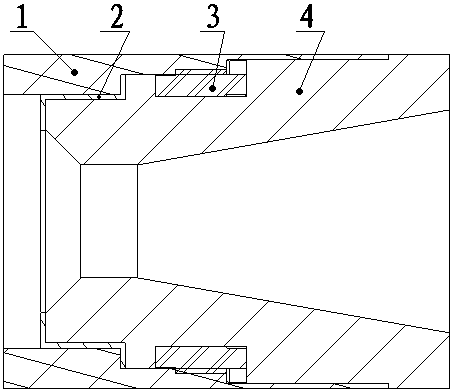

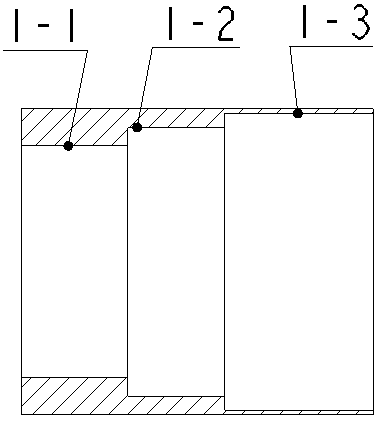

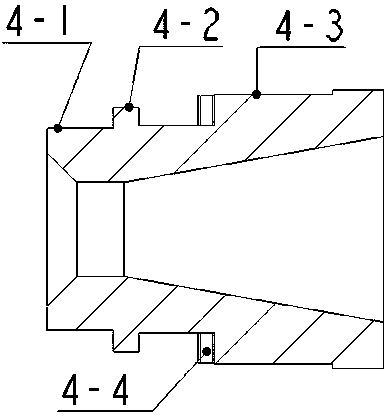

[0016] figure 1 Among them, the present invention includes a nozzle housing 1, a sealant 2 for sealing the connection gap, a retaining ring 3 for connection and fixing, and a nozzle expansion section 4 for limiting the throat liner and converting energy. The stop ring 3 is placed in the concave annular installation groove and the limit groove corresponding to the nozzle expansion section 4, the sealant 2 is basically evenly applied on the corresponding surface of the nozzle expansion section 4, and then the stop ring 3 and The corresponding thread of the nozzle housing 1 enables the nozzle expansion section 4 to be firmly connected to the rear section of the nozzle housing 1, and enables the sealant 2 applied on the nozzle expansion section 4 to be evenly distributed on the corresponding curved surface , to fill up the corresponding curved surfaces of the nozzle housing 1 and the nozzle expansion section 4 that need to be sealed. During the installation and docking process of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com