Subsea pipeline floating ball type flexible washing protection device

A technology for submarine pipelines and protective devices, which is used in pipeline protection, pipeline damage/wear prevention, pipeline laying and maintenance, etc., can solve problems such as high cost and poor reliability, and achieve low overall cost, easy construction and maintenance, and low cost. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] specific implementation

[0024] The present invention will be further described below in conjunction with the accompanying drawings.

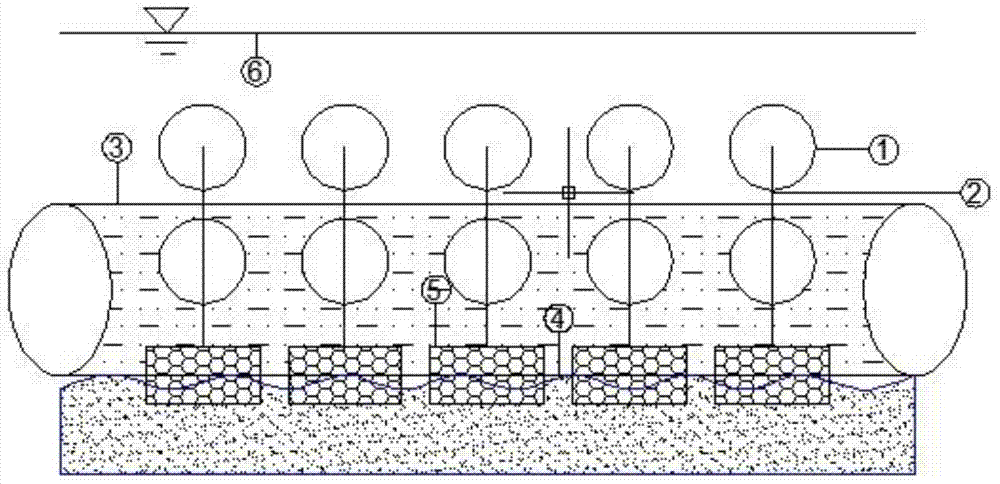

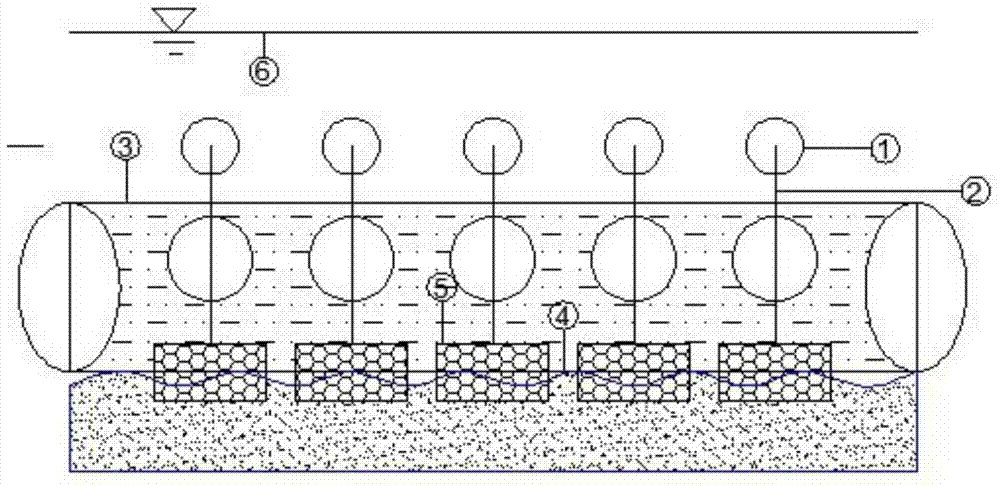

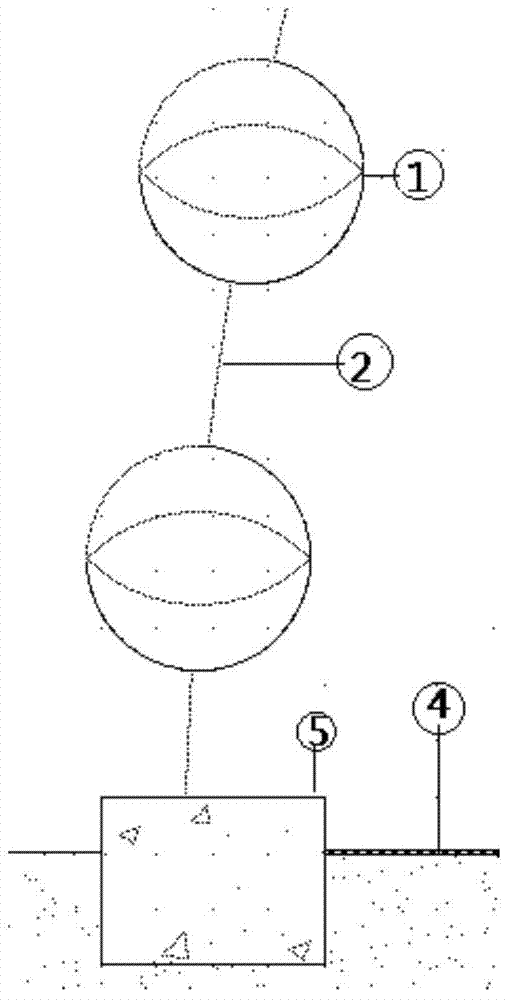

[0025] The technical principle of the present invention is: use a series of floating balls arranged along the pipeline to form a porous medium barrier to the water flow, reduce the flow velocity of the near-bottom water flow, and push the high-speed water flow upward to reduce the sediment start near the pipeline, It forms an effect similar to that of an onshore windproof pseudo-dust net; in addition, the water flowing through the floating ball will form a vortex around the floating ball, which will cause the vortex-induced vibration or swing of the floating ball, which can effectively dissipate the energy of the water flow and achieve the purpose of reducing local erosion of the pipeline.

[0026] The device of the present invention is composed of three or more floating ball protection units, and each floating ball protection unit is m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com