Flat type multi-core comprehensive wiring optical fiber cable and corresponding wiring structure thereof

A fiber optic cable and integrated wiring technology, applied in the direction of fiber mechanical structure, light guide, optics, etc., can solve the problems of disorganized fiber jumper wiring, inconvenient maintenance and expansion of trunking, and large link light attenuation, etc., to achieve excellent shrinkage resistance performance, Outstanding environmental performance, convenient and fast construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

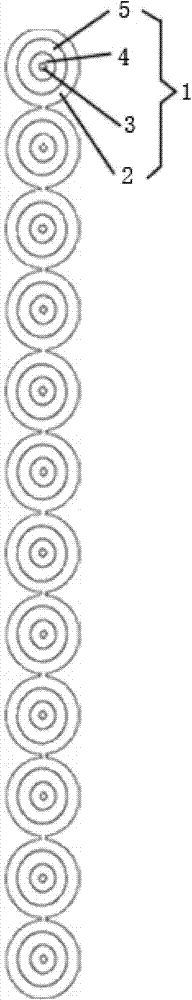

[0021] A flat multi-core integrated wiring fiber optic cable, see Figure 1 ~ Figure 3 : It includes at least three optical fibers 1, all the optical fibers 1 are arranged in parallel and horizontally, the outer sheaths 2 of adjacent optical fibers 1 are connected to each other, the highest points of the outer sheaths 2 of all the optical fibers 1 are on the same plane, and all outer sheaths The lowest point of the jacket layer 2 is on the same plane.

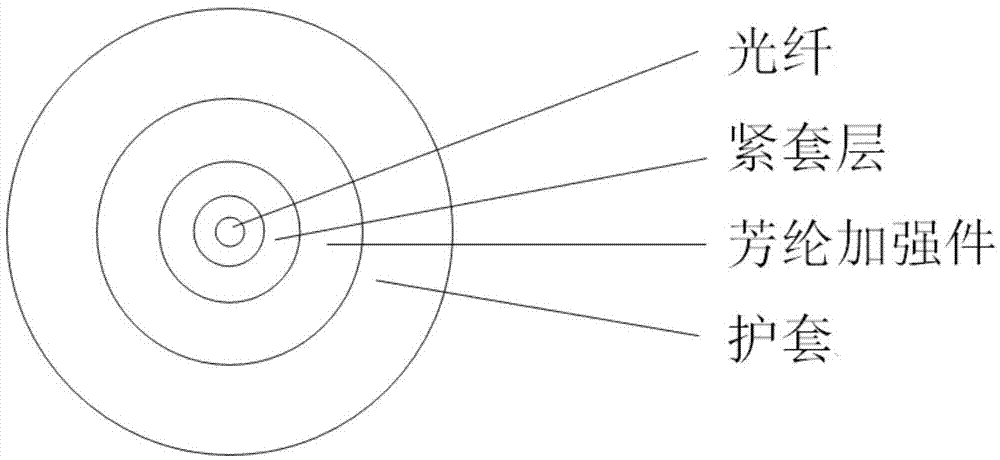

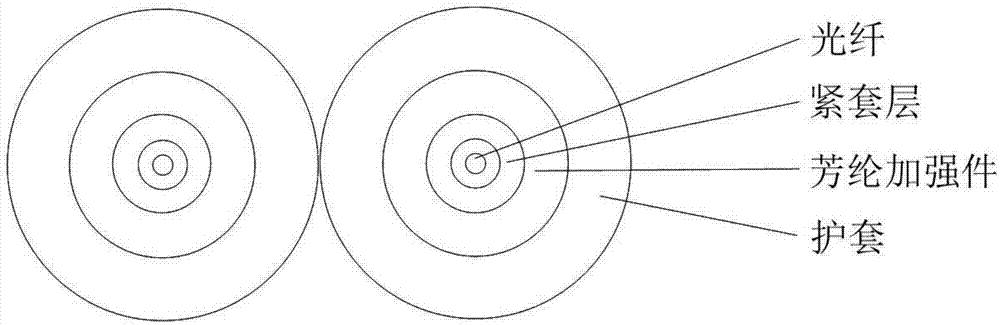

[0022] In the specific embodiment, the preferred number of optical fibers is 12; the cross section of each optical fiber 1 is respectively a central optical fiber 3, a tight sleeve layer 4, a non-metallic strength member 5, and an outer sheath layer 2 from the inside to the outside, and each optical fiber 1 The central optical fiber 3, the tight sleeve layer 4, and the non-metallic strengthening member 5 are arranged independently of each other centering on the center of the respective central optical fiber 3, and the outer she...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com