Separated type switch socket

A separate and switchable technology, applied in the installation of electrical components, coupling devices, connecting parts, etc., can solve the problems of increasing the difficulty and cost of on-site construction, wall damage, panel damage, etc., and achieve safe and convenient replacement and maintenance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

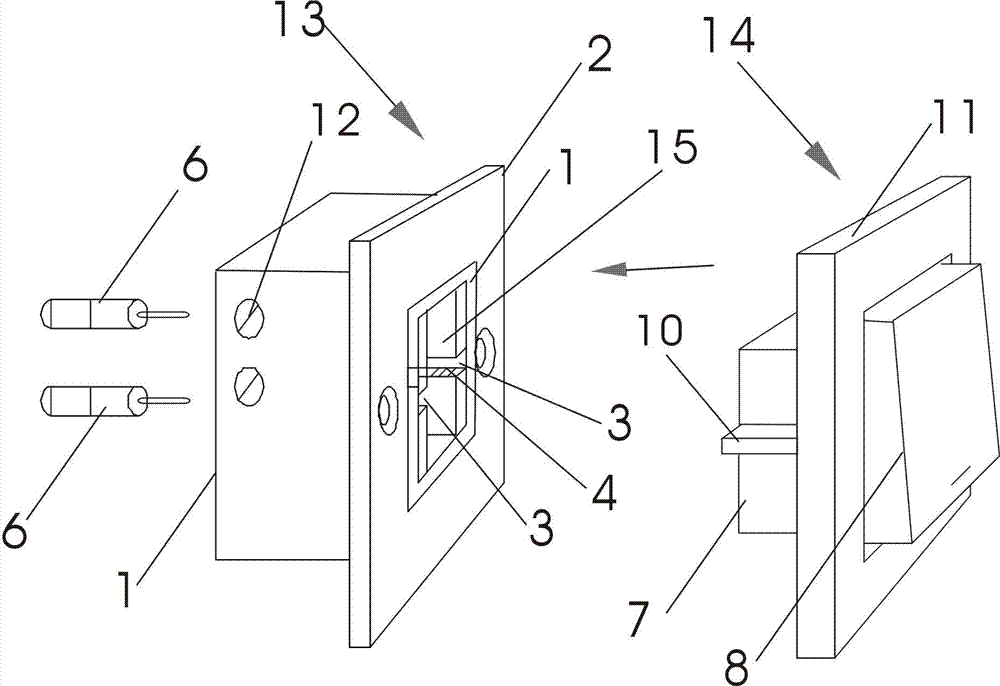

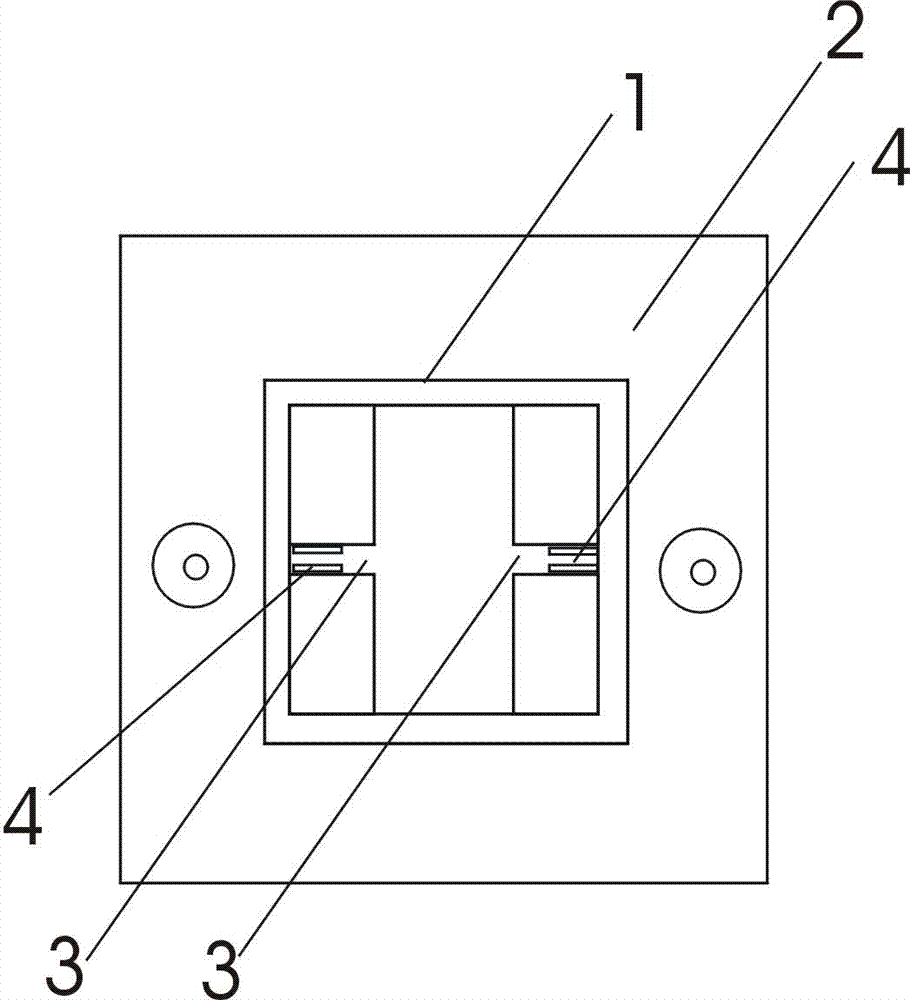

[0019] Example 1: see Figure 1-6 , a separate switch socket, including a junction bottom box 13, a panel 14, the junction bottom box 13 includes a wiring base 1 and a mounting bracket 2 installed in the wiring base 1, the mounting bracket 2 is located at the front end of the wiring base 1, and the installation A through hole in the middle of the bracket 2 communicates with the hollow structure 15 .

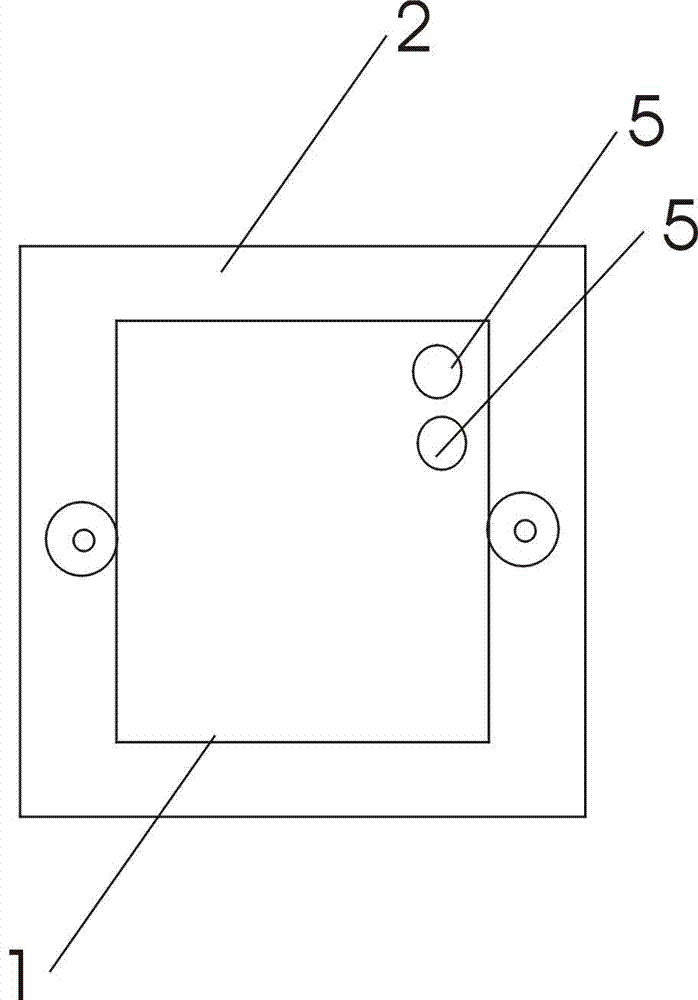

[0020] The terminal base 1 is a hollow structure 15, and there are at least two insertion grooves 3 on the inner wall of the hollow structure 15, and the insertion grooves 3 respectively hide metal contacts 4, and the metal contacts 4 are respectively It is electrically connected with the two base terminals 5.

[0021] The panel 14 includes a rear seat 7 connected to a switch button 8 or connected to a socket hole 9 .

[0022] There are at least two exposed metal protrusions 10 on the outside of the rear seat 7, and an insulating frame 11 for fixing the panel is set around the ...

Embodiment 2

[0028] Example 2: see Figure 7 , The difference from Embodiment 1 is that the back seat 7 is connected to the socket hole 9, and there is a line in the back seat 7 connected to the metal protrusion 10.

[0029] In the present invention, a plurality of switch buttons and socket holes can be arranged in the panel 14 at the same time.

[0030] The present invention can be directly installed on the wall body, and can also be installed in the existing switch socket bottom box for use. For example, for a switch socket in an existing installed wall, the existing panel is removed, and the junction bottom box of the present invention is placed in the existing switch socket bottom box.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com