An assembly jig and assembly method of square iron and coil of moving iron unit

A technology for assembling jigs and coils, applied to electrical components, sensors, etc., can solve the problems of low assembly efficiency and high defective rate, and achieve the effects of accurate and convenient positioning, easy removal, and convenient disassembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

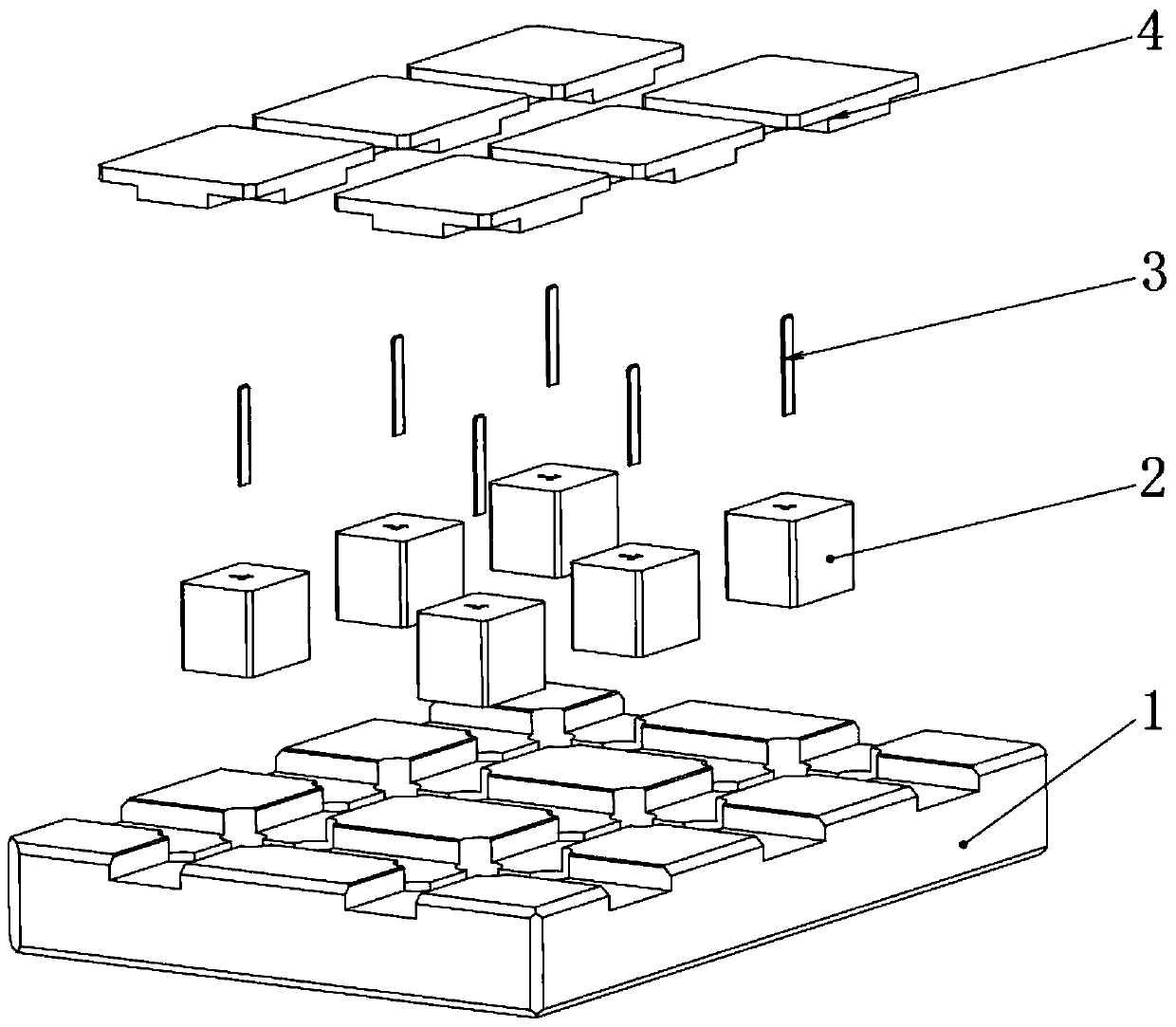

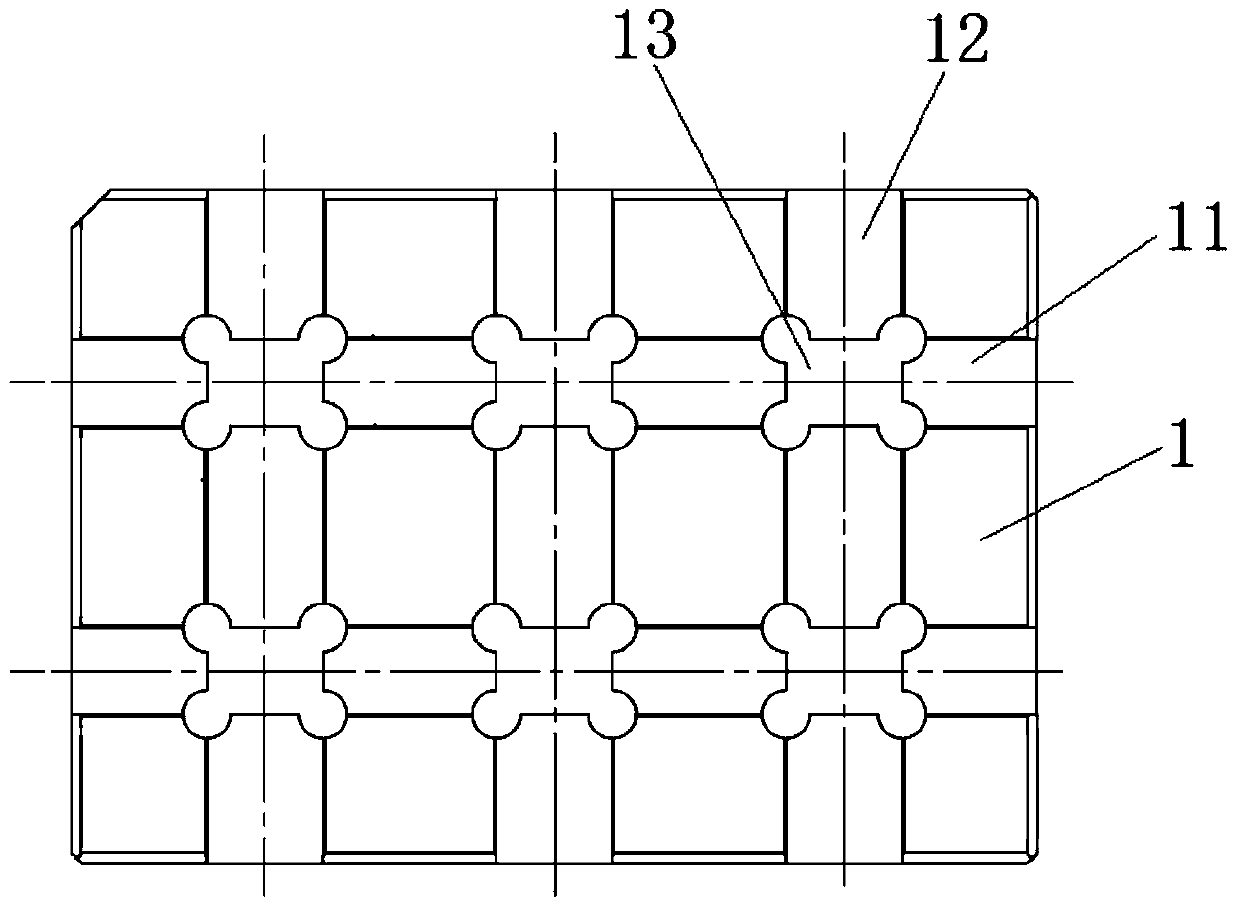

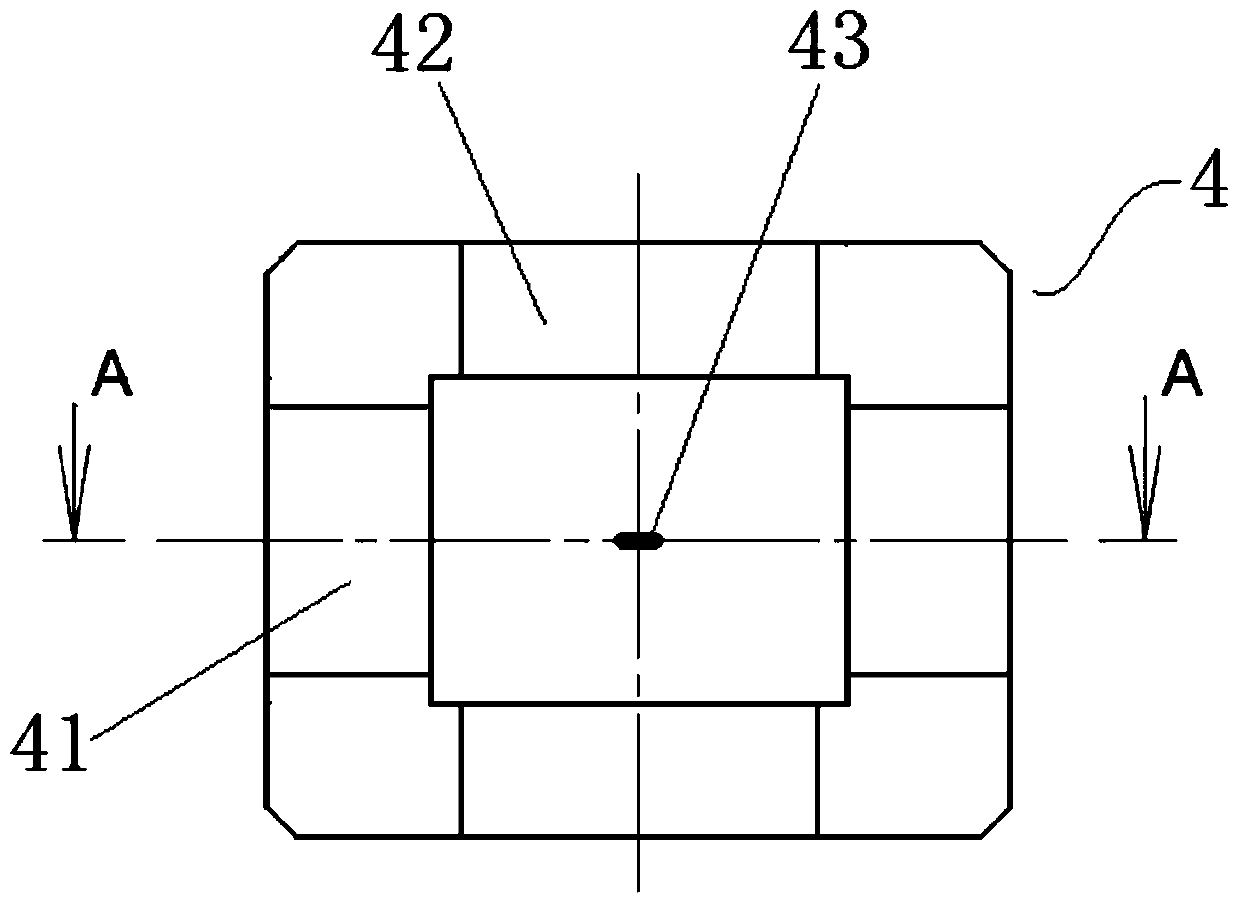

[0038] Combine Figure 1 to Figure 4 As shown, the assembly jig for square iron and coil of the moving iron unit of this embodiment includes a bottom plate 1 and a carrier board 4, the bottom plate 1 is used to install the positioning square iron, and the carrier 4 is used to install the positioning induction coil. Among them, such as figure 2 As shown, the bottom plate 1 is provided with one or more horizontal mating grooves 11 and one or more longitudinal mating grooves 12, the horizontal mating grooves 11 and the longitudinal mating grooves 12 are perpendicular to each other, forming a rectangular array arrangement In the cross position of the horizontal inserting groove 11 and the longitudinal inserting groove 12, an insert fixing groove 13 is provided. The insert fixing groove 13 is provided with an insert 2, and the middle of the insert 2 is provided with a square iron for positioning The insert 3 is a rod-shaped component inserted in the through hole provided on the ins...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com