A distillation tower

A distillation tower and rectification technology, which is applied in the field of distillation and rectification towers, can solve the problems of increasing production costs and wasting energy, and achieve the effects of low cost, small footprint, and small heat loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be further described below in conjunction with the accompanying drawings.

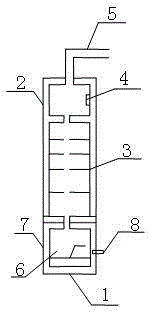

[0012] The present invention discloses a distillation tower. The tower body includes a rectifying layer 1 at the bottom layer, a cooling layer 2 at the top layer, and more than one layer of tower sections 3 stacked between them. Each layer of tower sections 3 are provided with a feeding port, the top cooling layer 2 is equipped with a condenser 4, the outlet end of the condenser 4 is connected to the discharge pipe 5, and the basic rectification layer 1 includes an inner cylinder 6 and an outer cylinder 7, and the inner cylinder 6 is used to contain the distillate, and the heat transfer oil is contained between the outer cylinder 7 and the inner cylinder 6; the heating rod extends through the outer cylinder 7 into the heat transfer oil for heating the heat transfer oil, and the rectification layer 1 of the base layer has a hollow The interlayer is heated and a layer of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com