Gas membrane separation device capable of eliminating static electricity and method

A separation device and gas membrane technology, applied in the field of membrane separation, can solve the problems of reducing the effective area of the membrane module, the metal wire is easy to scratch the membrane surface, and the metal wire is easy to contact poorly, so as to avoid poor contact and poor corrosion resistance , the effect of reducing the effective area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

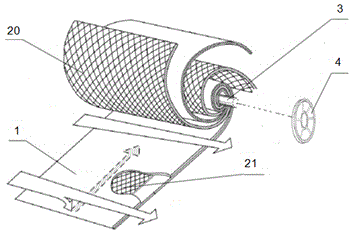

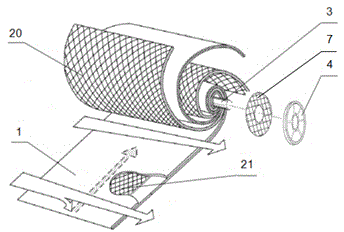

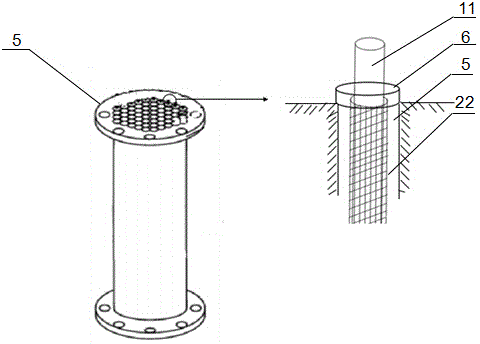

[0050] This embodiment provides a method for eliminating static electricity in a gas membrane separation device, wherein the gas membrane separation device includes a membrane module, at least part of which is made of conductive materials (conventional conductive materials are sufficient). In the method described in the embodiment, the conductive mesh is used as the feed-side flow mesh and / or the permeate-side flow mesh in the gas membrane separation device and is in contact with the conductive material.

Embodiment 2

[0052] Compared with Example 1, the only difference is that in the method described in this embodiment, the wire diameter of the flow guide mesh on the feed side is 1mm, and the aperture is 5mm; the wire diameter of the flow guide mesh on the permeation side is 0.5mm, and the aperture is 2mm. , both of which are prepared from conductive plastics, wherein polyvinyl chloride is used as the plastic masterbatch in the conductive plastics, and the conductive material in the conductive plastics is graphite powder.

Embodiment 3

[0054] Compared with Example 1, the only difference is that in the method described in this embodiment, the wire diameter of the feed side diversion net is 0.5 mm, and the aperture is 2 mm; the diameter of the permeation side diversion net is 0.5 mm, and the aperture is 2 mm. 2mm. Both are made of conductive plastic, wherein polypropylene is used as the plastic masterbatch in the conductive plastic, and the conductive material in the conductive plastic is carbon black.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap