Production technology of preparing orally taken solid preparation

A production process and solid preparation technology, which is applied in the field of production process for preparing oral solid preparations, can solve the problem of low uniformity of powder original drug, and achieve the effect of increasing uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

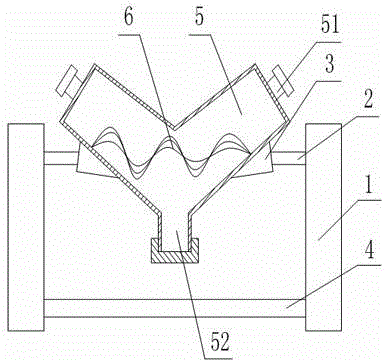

[0018] Such as figure 1 As shown, the production process for preparing oral solid preparations includes the following steps: first, granulation, using a granulator to granulate the raw materials for oral preparations to form granular powder; secondly, mixing, using a mixer to granulate the raw materials for oral preparations and the auxiliary materials are mixed; then, the mixed powder is tableted by a tablet machine; then, the tablets are packaged in aluminum and plastic; finally, the outer packaging is performed, and the mixer includes a V-shaped mixing bin 5. The two ends of the V-shaped mixing bin 5 are symmetrically provided with a feed port 51, and the bottom of the V-shaped mixing bin 5 is provided with a discharge port 52. The outer wall of the V-shaped mixing bin 5 passes through two symmetrical shafts. 2 is connected with the symmetrically arranged fixed seat 1, and the outer wall of the V-shaped mixing bin 5 is provided with a reinforcing rib 3 at the junction of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com