Nano carbon crystal

A nano-carbon and nano-silver technology, which is applied in biocides, plant growth regulators, animal husbandry, etc., can solve the problems of activated carbon lifespan of only 5-6 months, pollution, secondary pollution, etc., and achieve the effect of inhibiting the growth of bacteria

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

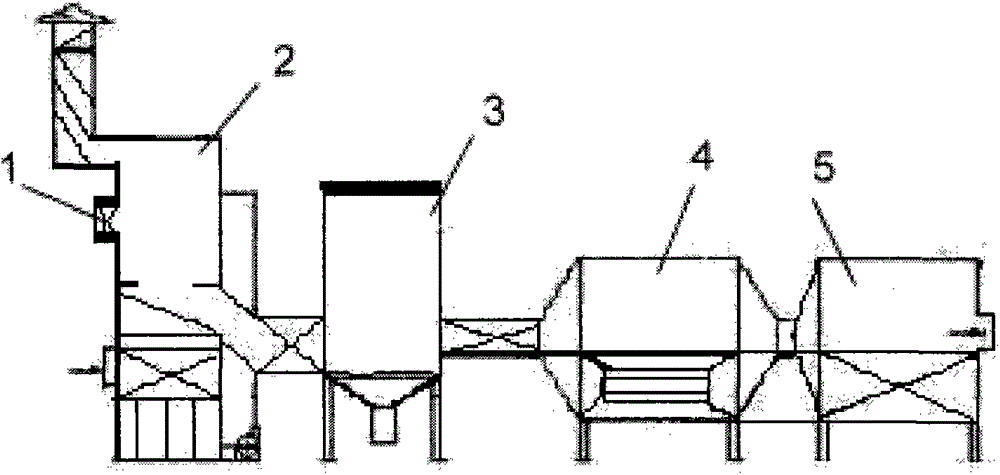

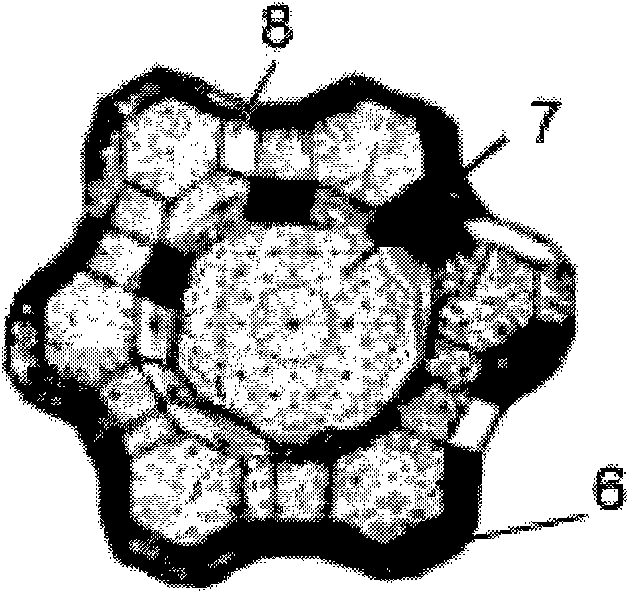

[0021] The nano-carbon crystals in the present embodiment are made of the following raw materials in parts by weight: 5 parts of coconut shell charcoal, 9 parts of clinoptilolite, 13 parts of attapulgite, 15 parts of sepiolite, TiO 2 1 part, 0.03 parts of nano-silver, the production process of the above-mentioned nano-carbon crystals is as follows: first, the raw materials of coconut shell charcoal, zeolite, attapulgite and sepiolite that have been screened are washed, disinfected and sterilized, and then mechanically pulverized by ultra-fine powder. The raw materials are directly crushed into superfine powder, and TiO is added according to the above ratio 2 and nanosilver. Then, using the centrifugal acceleration equivalent to 110 times the acceleration of gravity generated by the high-speed rotation of the high-gravity rotating bed, the mass transfer and micro-mixing between the phases are greatly enhanced, and after being evenly blended, a perfect layered skeleton is formed...

Embodiment 2

[0023] The nano-carbon crystals in the present embodiment are made of the following raw materials in parts by weight: 8 parts of coconut shell charcoal, 12 parts of mordenite, 15 parts of attapulgite, 17 parts of sepiolite, TiO 2 2 parts, 0.01 part of nano-silver, the production process of the above-mentioned nano-carbon crystals is as follows: first, the raw materials of coconut shell charcoal, zeolite, attapulgite and sepiolite that have been screened are washed, sterilized, and sterilized, and then mechanically pulverized by ultra-fine powder. The raw materials are directly crushed into superfine powder, and TiO is added according to the above ratio 2 and nanosilver. Then, the centrifugal acceleration equivalent to 110 times the acceleration of gravity generated by the high-speed rotation of the high-gravity rotating bed greatly strengthens the mass transfer and microscopic mixing between the phases. After uniform mixing and molecular sieve activation treatment, a perfect l...

Embodiment 3

[0025] The nano-carbon crystal in the present embodiment is made of the following raw materials in parts by weight: 6 parts of coconut shell charcoal, 11 parts of analcite, 14 parts of attapulgite, 16 parts of sepiolite, TiO 2 1.5 parts, 0.02 parts of nano-silver, the production process of the above-mentioned nano-carbon crystals is as follows: first, the raw materials of coconut shell charcoal, zeolite, attapulgite and sepiolite that have been screened are washed, sterilized and sterilized, and then mechanically pulverized by superfine powder. The raw materials are directly crushed into superfine powder, and TiO is added according to the above ratio 2 and nanosilver. Then, the centrifugal acceleration equivalent to 110 times the acceleration of gravity generated by the high-speed rotation of the high-gravity rotating bed greatly strengthens the interphase mass transfer and microscopic mixing. After uniform blending and molecular sieve activation, a perfect layered structure i...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap