Crushing water washing drum sorting machine

A sorter, drum technology, applied in the direction of solid separation, sieve, grid, etc., can solve the problems of unsuitable for fast moving operation, cumbersome operation, complicated process, etc., to reduce equipment production cost, safe and simple operation, improve The effect of work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

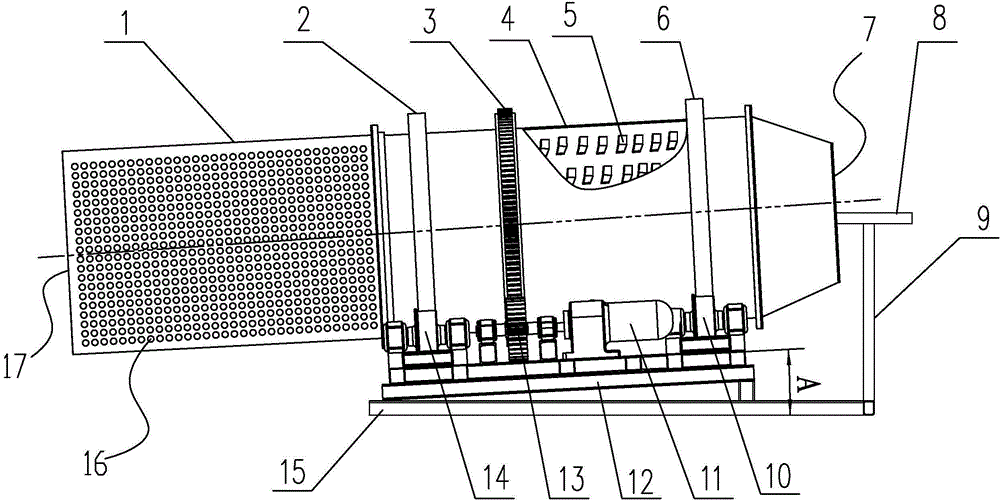

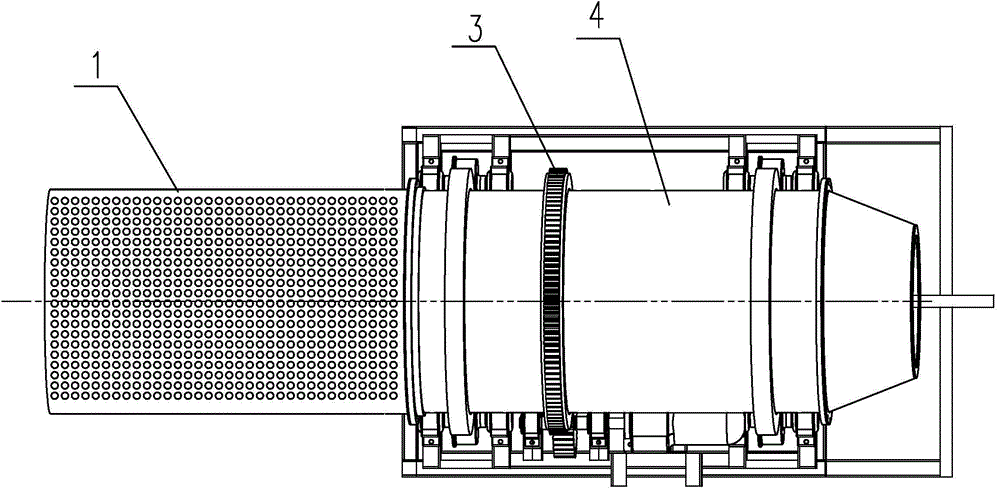

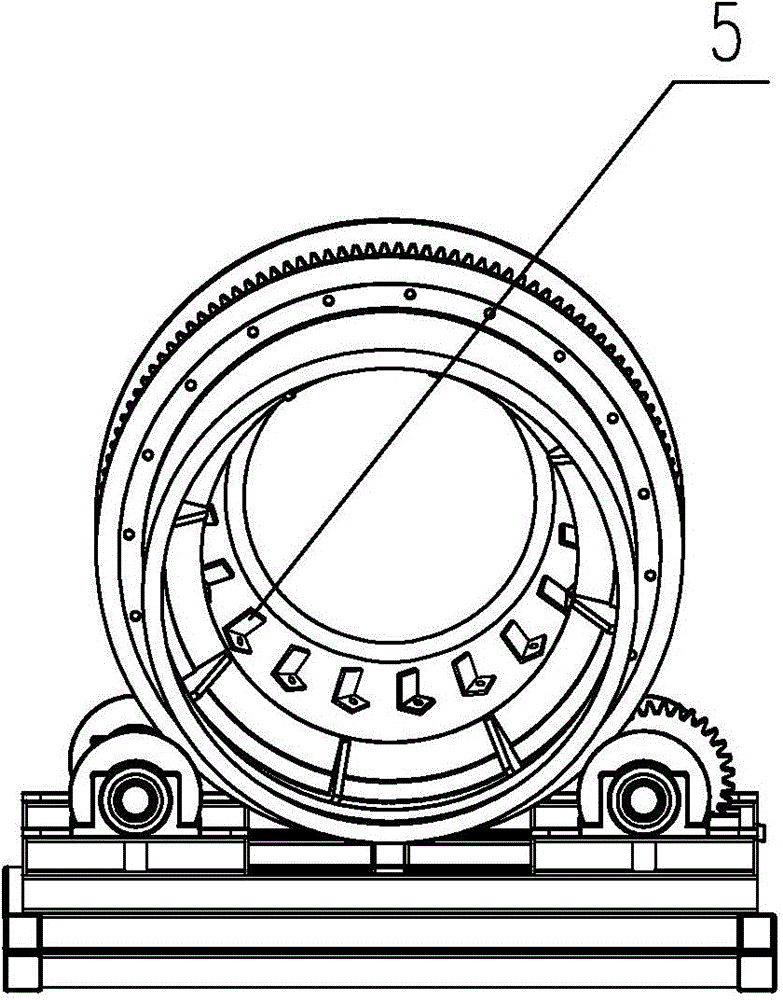

[0015] Such as Figure 1 to Figure 3 As shown, the crushing and washing drum separator of the present invention includes a crushing drum 4, a sieve cylinder 1, and a base. The rear end of the outer wall is covered with a rear rolling ring 2, and the outer wall of the crushing drum 4 is covered with a driven gear 3 relatively fixed to the outer wall of the crushing drum 4 near the middle. The crushing drum 4 is placed on the base as a whole through the front rolling ring 6 and the rear rolling ring 2. 15 on the front idler 10 and rear idler 14, the screen drum 1 is fixedly connected to the tail of the crushing drum 4, and the wall of the screen drum 1 has a screen hole 16, and the screen hole 16 can be moved from the drum 4 to the The direction of the outlet 17 increases gradually in two or more stages, that is, the aperture of the screen hole 16 on the screen cylinder 1 gradually increases in two or more stages from the front end to the rear end. The base 15 is also provided ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com