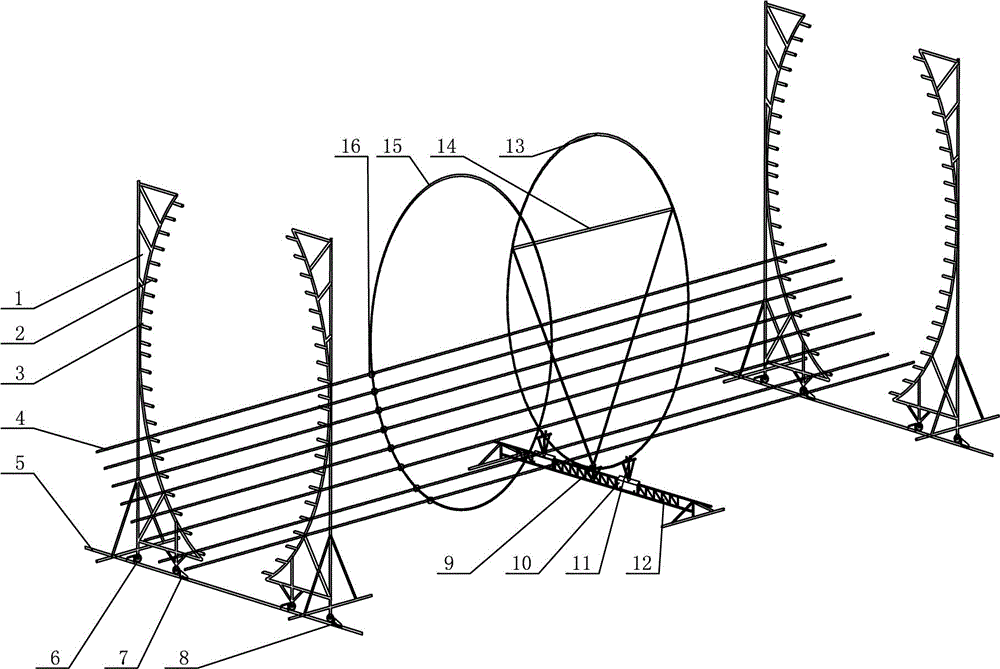

Vertical full-annular-direction positioning jig frame device system and construction technology for large-diameter pile foundation reinforcement cage

A construction technology and technology for positioning tires, which is applied in the field of pile foundation reinforcement cage auxiliary positioning installation device system and construction technology, can solve the problems of high tire mold processing costs, time-consuming and labor-intensive production, poor economy, etc., and achieve the effect of ensuring dimensional accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

[0039](1) Fabrication and installation of the vertical positioning tire frame 1. The vertical positioning tire frame 1 is made of ordinary threaded steel bars, and two longitudinal reinforcement vertical positioning tire frames 1 that can be butted into the overall circular section of the reinforcement cage are made according to the 1 / 2 arc of the reinforcement cage diameter required by the design; in each reinforcement cage Longitudinal ribs 4 are welded at the designed position, and comb holes 3 are formed with comb-teeth bars 2 made of ordinary threaded steel bars; mobile pulleys 6 are installed at the bottom of vertical positioning tire frame 1; tire frame moving rails 5 are set on the concrete foundation work platform, and vertical Type positioning tire frame 1 is installed on the tire frame moving rail 5.

[0040] (2) Fabrication and installation of the support tire frame 12. Adopt common straight threaded steel bar to make support tire frame 12, select support point an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com