Manipulator device of multistage cold former

A technology of manipulator and cold heading machine

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

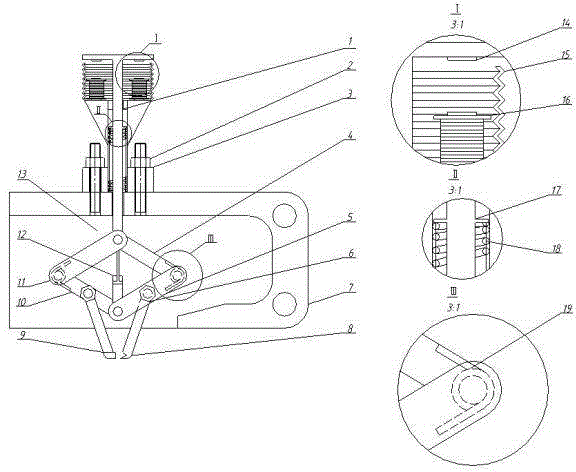

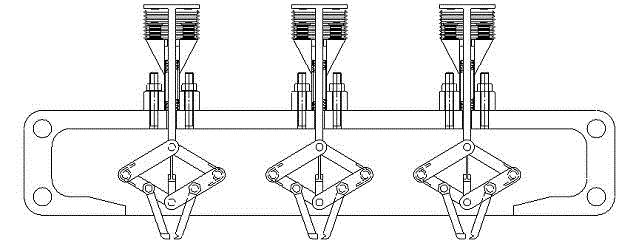

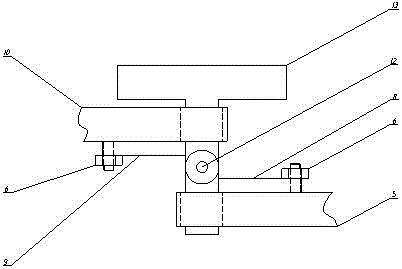

[0016] Preferred embodiments of the present invention are described in detail as follows in conjunction with accompanying drawings:

[0017] see figure 1 and figure 2 , a multi-station cold heading machine manipulator device, including a rubber fixing ring 1, a screw and a nut 2, a tie rod guideway fixing seat 3, composed of a first rod 5, a second rod 10, a third rod 11, a first rod Four-bar structure composed of four rods 4, adjusting nut 6, manipulator frame 7, manipulator right part 8, manipulator left part 9, miniature hydraulic rod 12, manipulator frame rear panel 13, magnet block 14, insulating shell 15, electromagnetic coil 16 , a T-shaped pull rod 17, a return spring 18 and a torsion spring 19; the rear panel 13 of the manipulator frame is fixed on the rear surface of the manipulator frame 7; The return spring 18 is fixed on the pull rod guideway fixing seat 3 through the rubber fixing ring 1, and two electromagnetic coils 16 and an insulating shell 15 are symmetri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com