A wireless measuring device for machine tool cutting force

A wireless measurement and cutting force technology, applied in the direction of measurement/indicating equipment, metal processing machinery parts, metal processing, etc., can solve the problems of current changes, simultaneous and real-time measurement, etc., to reduce additional torque and ensure safe operation , Improve the effect of measurement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be described in detail below with reference to the accompanying drawings and examples.

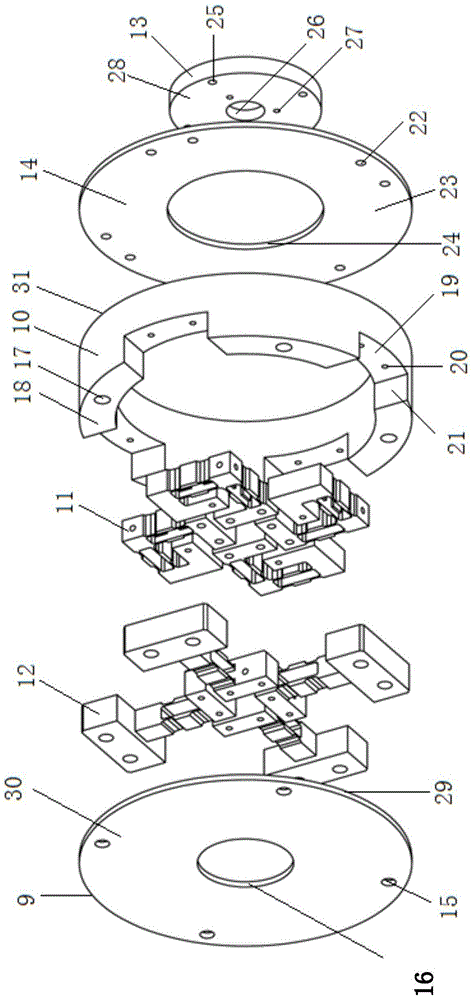

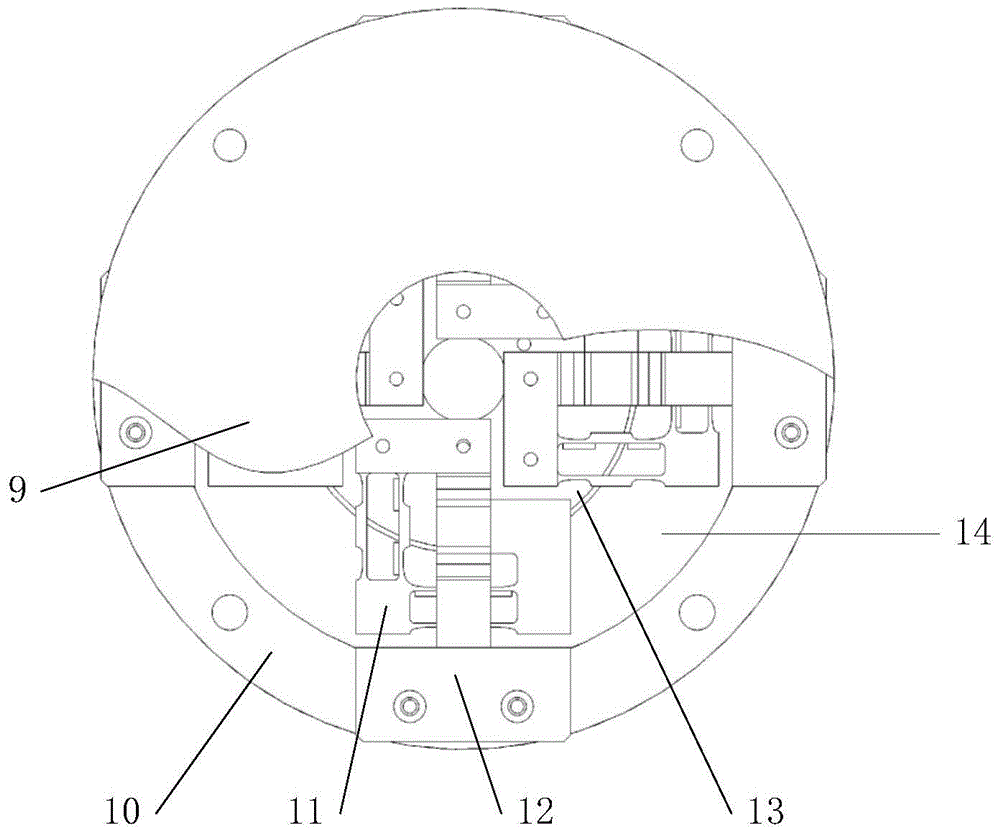

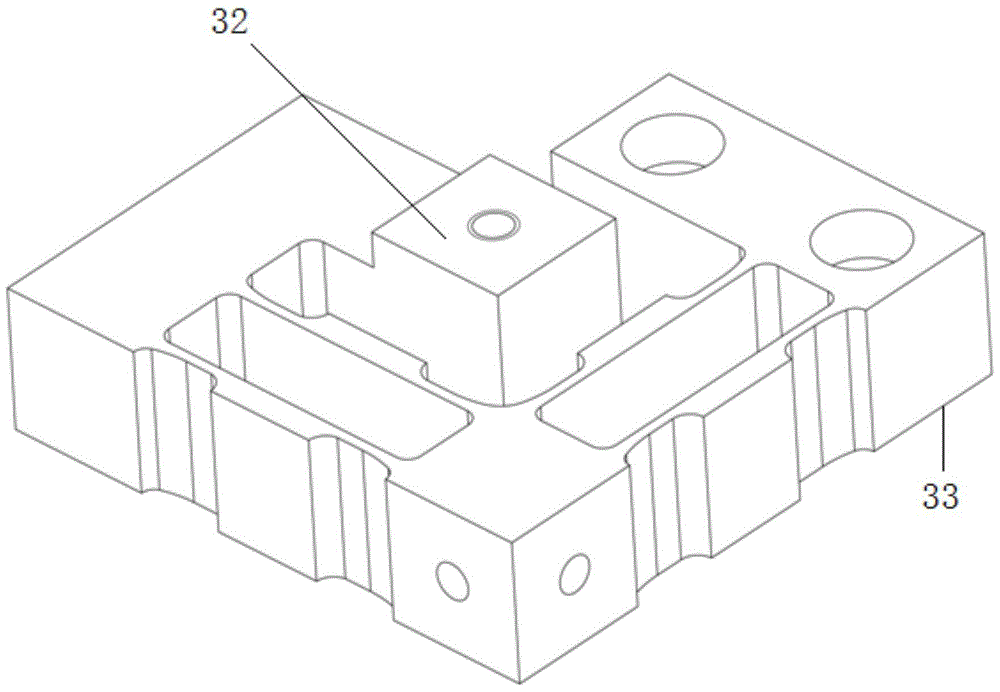

[0028] The present invention provides a wireless measuring device for machine tool cutting force, including an adapter plate 13, a front baffle 14, a mounting base 10, four three-axis force sensors, a back baffle 9 and a wireless module 3; the peripheral equipment is a turning spindle 1 , chuck 4, workpiece 5, milling cutter 6, moving slide 7 and milling spindle 8;

[0029] as attached figure 1 As shown, the adapter plate 13 is a circular rotary part, and its surface is respectively processed with a chuck installation connection hole 27 and a sensor force installation connection hole 25. The central hole on the adapter plate 13 is a chuck The positioning groove 26, the surface on one side of the adapter plate 13 is a force mounting connection plane 28 for the sensor;

[0030] The front baffle 14 is an annular plate-shaped part, and eight mounting holes 22 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com