Variable-freedom-degree modular mechanical arm

A technology of manipulators and degrees of freedom, applied in the field of manipulators, can solve the problems of inability to complete the combination and replacement of joints, poor flexibility, and different joint structures, etc., to achieve compact overall structure design, reduce costs, and facilitate internal wiring Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0052] The present invention will be further described in detail below in conjunction with the accompanying drawings.

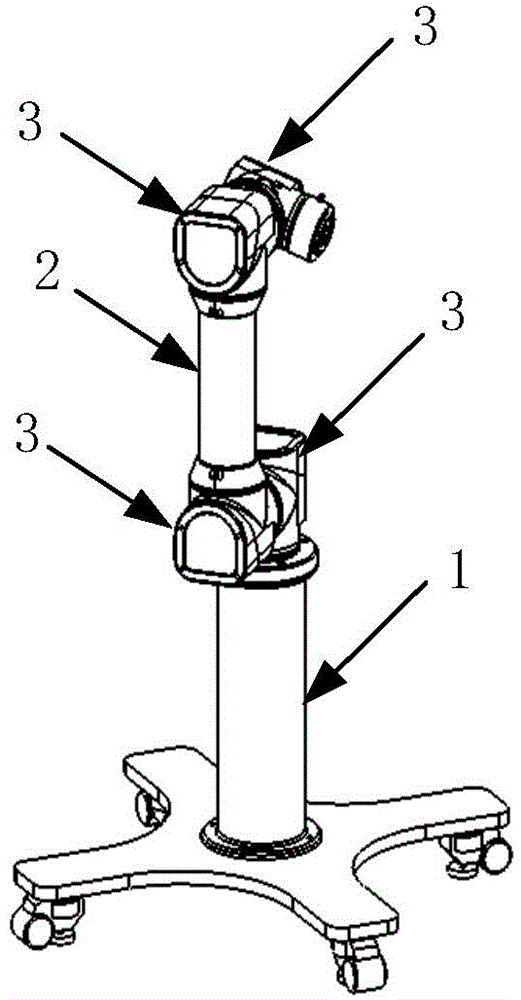

[0053] The modularized mechanical arm with variable degrees of freedom of the present invention includes a base 1, a mechanical arm link 2 and a mechanical arm joint 3; the base is used to support the mechanical arm and realize the setting and installation of the mechanical arm; the mechanical arm link 2 between the manipulator link 2 and the base 1, and between the manipulator link 2 and the end effector are all connected through the manipulator joints, as figure 1 shown.

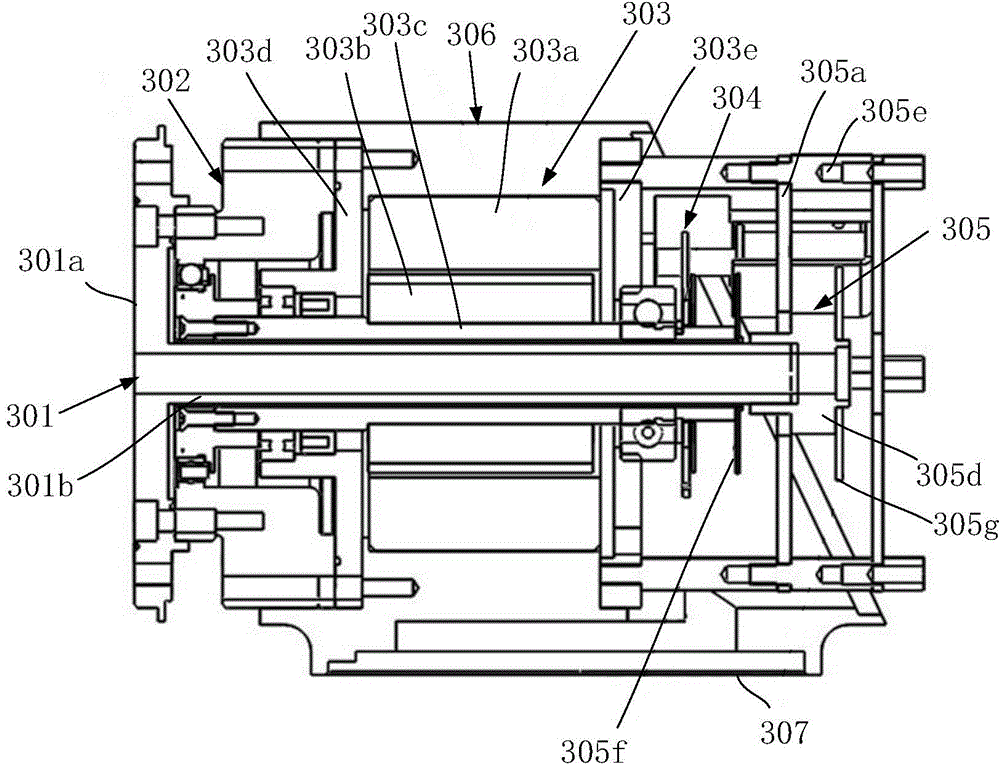

[0054] The mechanical arm joint 3 includes an output flange shaft 301, a harmonic reducer 302, a hollow shaft motor 303, a brake device 304, a double code disc positioning mechanism 305 and a housing 306, such as figure 2 shown.

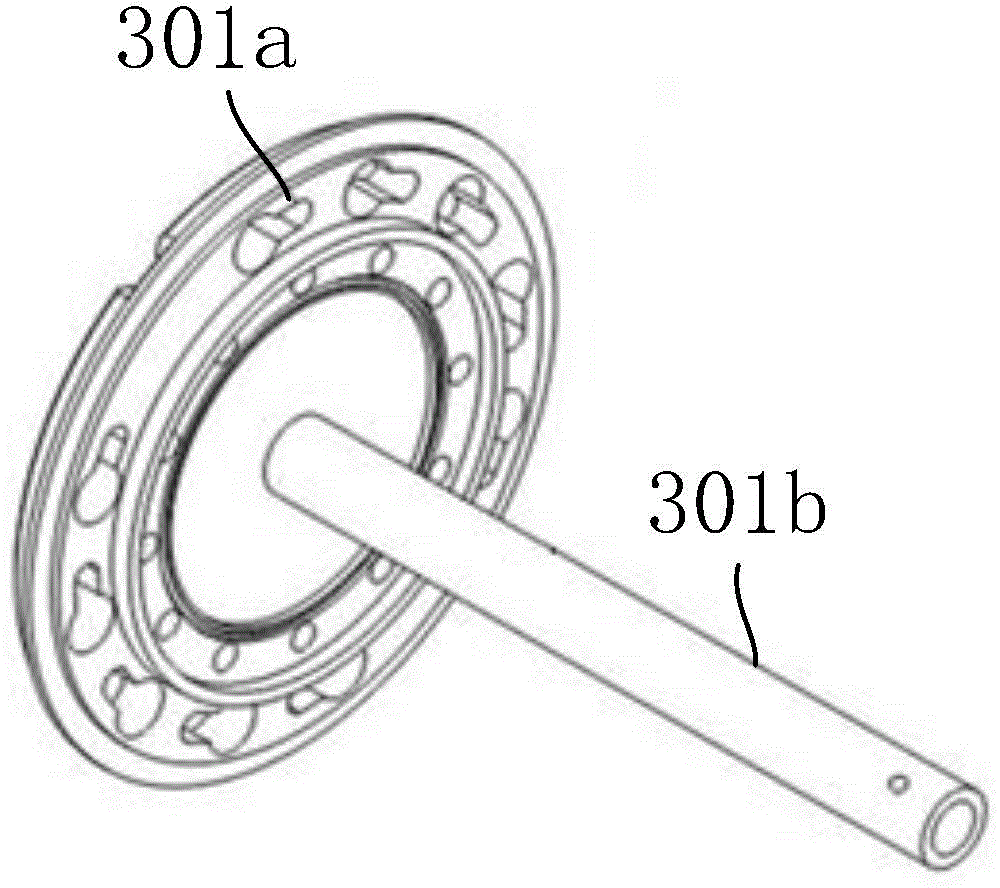

[0055] The output flange shaft 301 is an integral structure composed of two parts, the output flange 301a and the output shaft 301b, as image 3 As shown, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com