Differential control system for electric bridges of double-hub electric four-wheeler

An electric four-wheel vehicle and control system technology, applied in electric vehicles, control drives, vehicle components, etc., can solve the problems of complex control structure, high cost, lack of universality, etc., and achieve simple control algorithm, low cost, easy-to-achieve effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Below in conjunction with accompanying drawing, the present invention will be further described through embodiment.

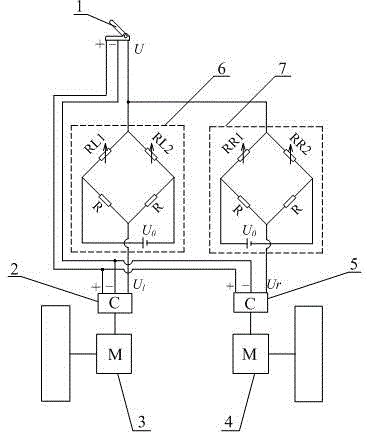

[0021] The double-hub type electric four-wheel vehicle bridge differential speed control system of the present invention, such as figure 1 As shown, the left bridge (6) in the system is composed of two fixed resistors with the same resistance and two outputs RL1 and RL2 of the adjustable resistor RL, and the right bridge (7) is composed of two fixed resistors with the same resistance and the two outputs RR1 and RR2 of the adjustable resistor RR; the fixed resistor resistance values of the left bridge (6) and the right bridge (7) are all equal; the total resistance values of the adjustable resistor RL and the adjustable resistor RR are equal, And it is twice the resistance value of the fixed resistor in the bridge.

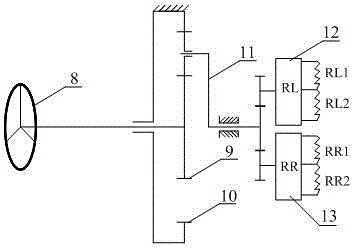

[0022] The steering wheel (8) is connected with the sun gear (9) of the planetary gear mechanism, the ring gear (10) is fixed, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com