A special beam transporter for railway T-beams with detection

A beam transporting machine and railway technology, applied in the field of beam transporting equipment, can solve the problems of reducing work efficiency, prolonging construction progress, low work efficiency, etc., achieving the effect of compact structure and eliminating potential safety hazards.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

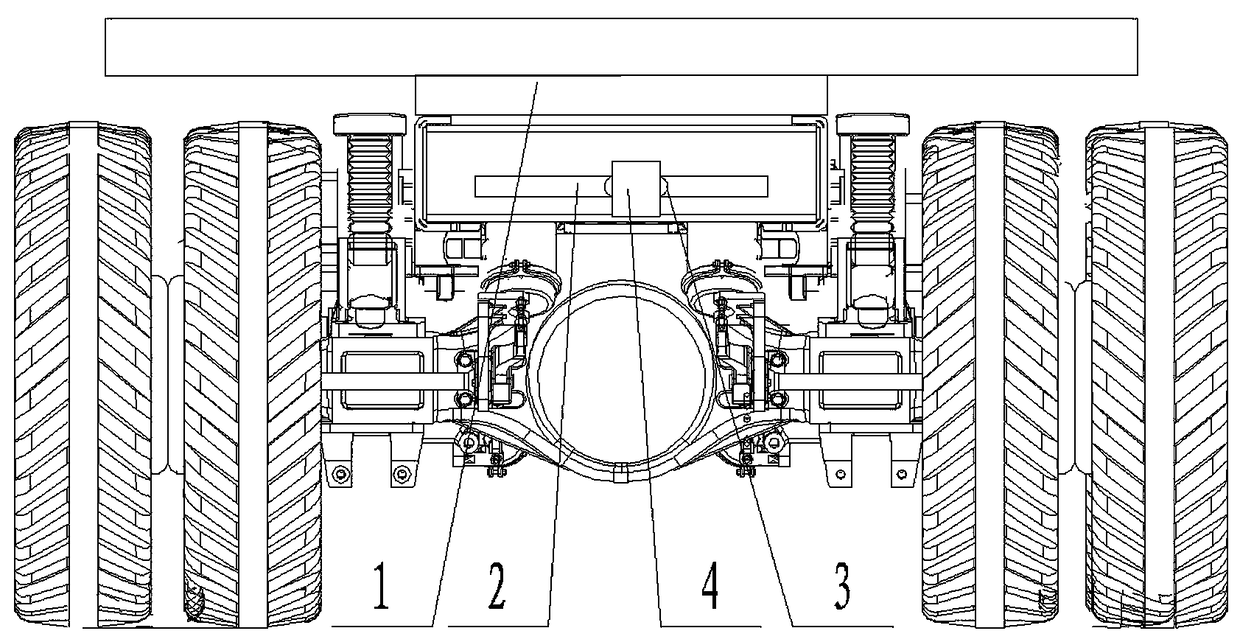

[0017] Embodiment 1: as figure 1 , 2 As shown, the present invention includes a frame 1 and a balance detection device arranged on the frame 1 . The balance detection device includes a level 2 arranged on the frame 1 and an air bubble 3 arranged in the liquid of the level 2; as a preferred solution, the balance detection device also includes an adjustable baffle 4 arranged on the frame 1, and the adjustable baffle 4 Can slide along the length direction of the spirit level 2. The frame 1 is provided with slide rails that allow the adjustable baffle 4 to slide along the length direction of the level 2, or the adjustable baffle 4 is set on the level 2 and the adjustable baffle 4 can slide along the length of the level 2. Adjusting the baffle plate 4 is more convenient and intuitive.

[0018] When it is empty, adjust the adjustable baffle 4 to cover the bubble 3 according to the position of the bubble 3, record the level 2, and when the beam transporter is loaded, the frame 1 i...

Embodiment 2

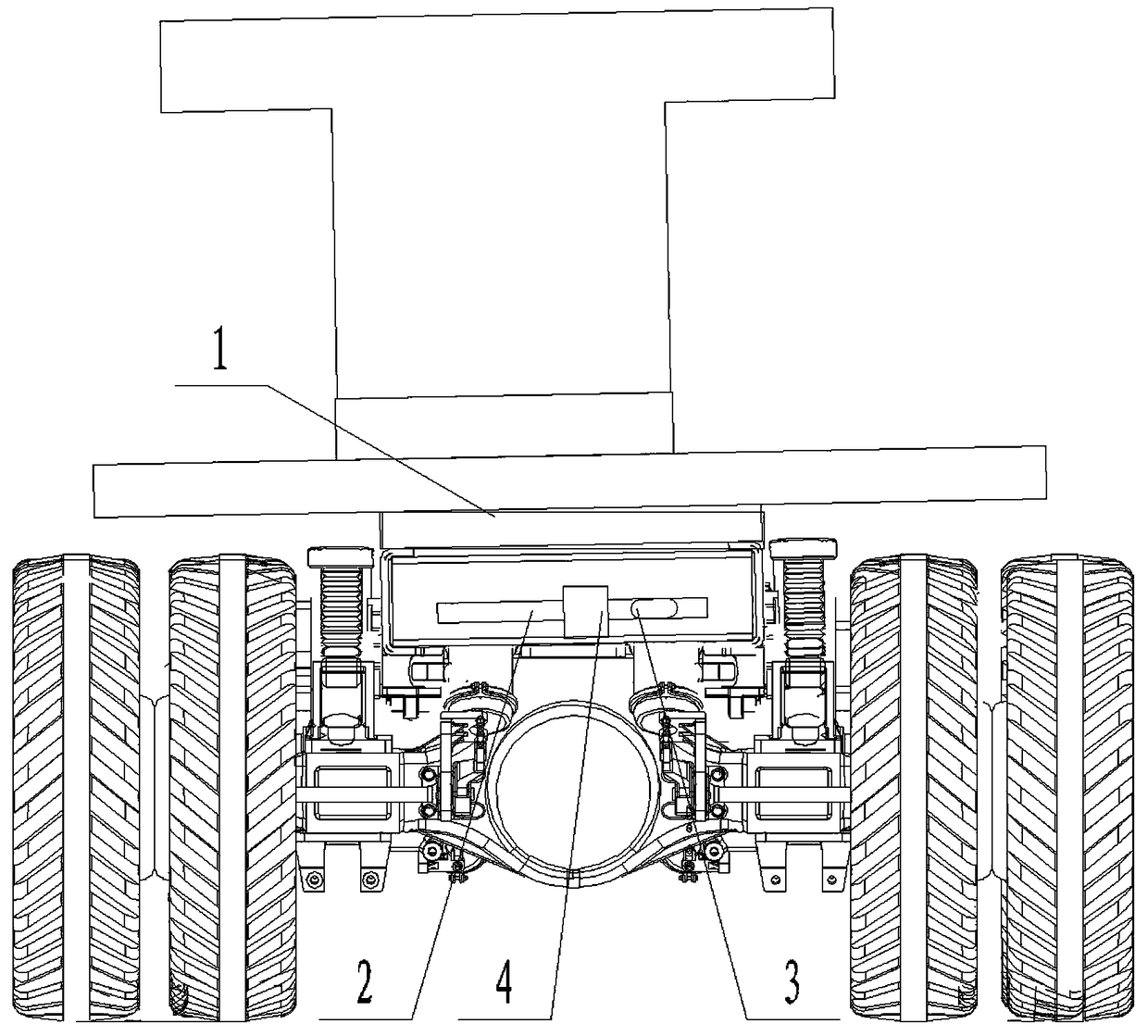

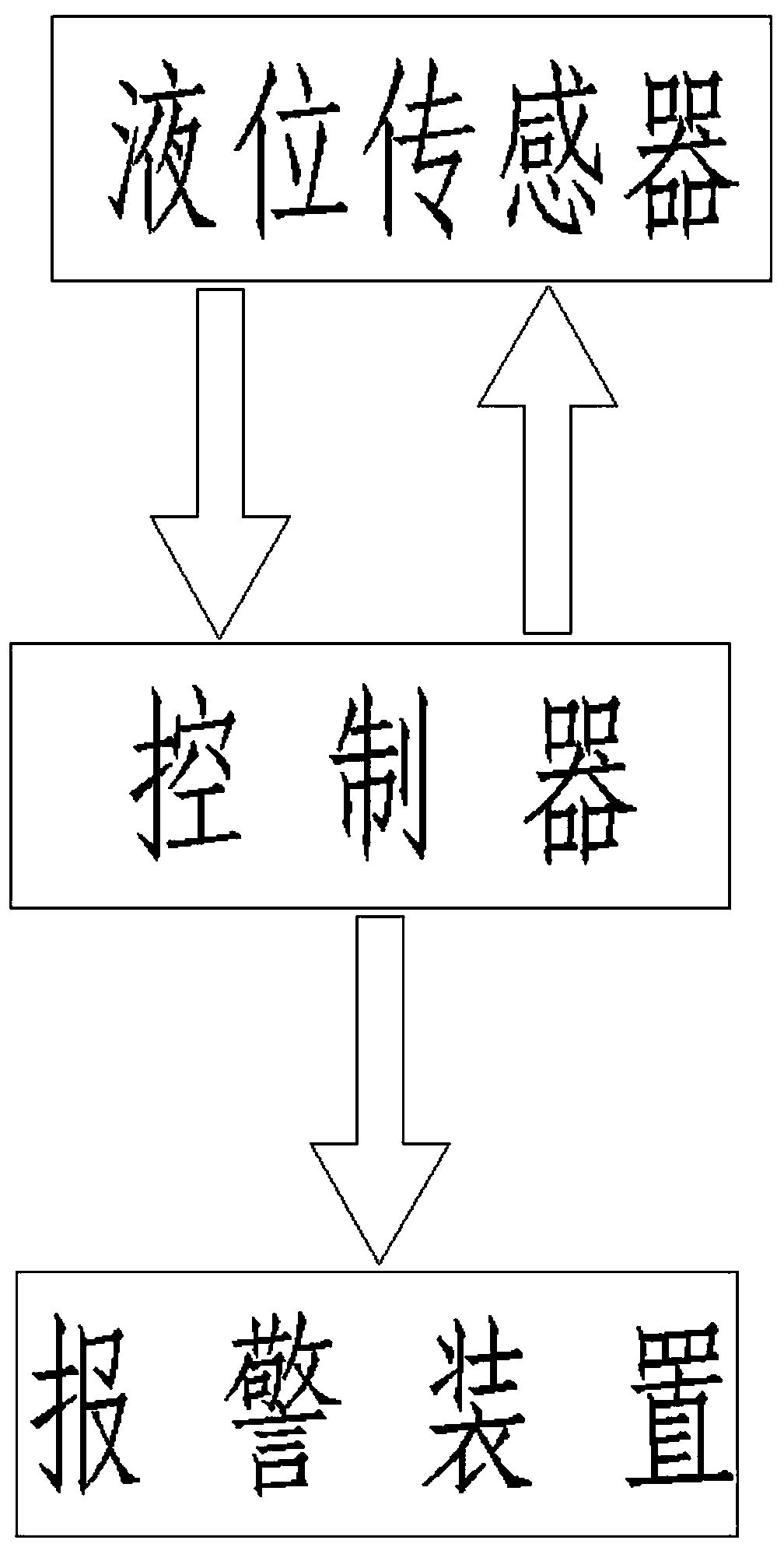

[0019] Embodiment 2: as Figure 3-5 As shown, the present invention includes a frame 1 and a balance detection device arranged on the frame 1 . The balance detection device is a U-shaped transparent liquid tube 5 filled with liquid; the balance detection device can also be an altimeter.

[0020] When no-load, measure the distance between an upper end surface B of the liquid in the U-shaped transparent liquid tube 5 and the reference plane A as h1, when the T-beam is placed, the upper end surface B of the liquid in the U-shaped transparent liquid tube 5 and the reference plane The distance of surface A is h2, according to the deviation distance Δh1=h1-h2, adjust the position of the actual T-beam on the beam transport machine.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com