Railway T-beam special transport equipment

A technology for transportation equipment and railways, which is used in transportation and packaging, vehicles for carrying long goods, power units, etc., and can solve problems such as prolonged construction progress, slow driving speed, and reduced work efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

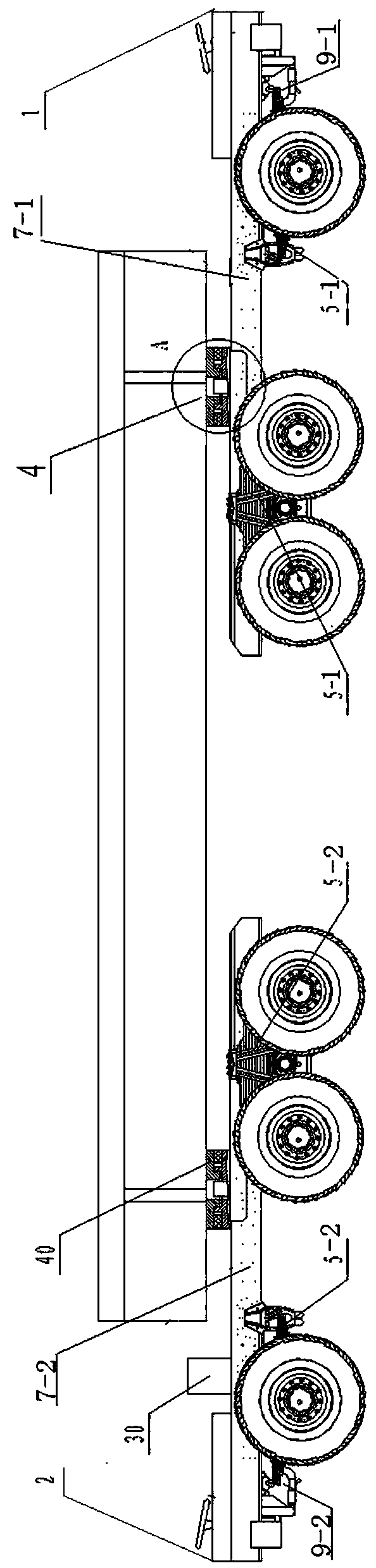

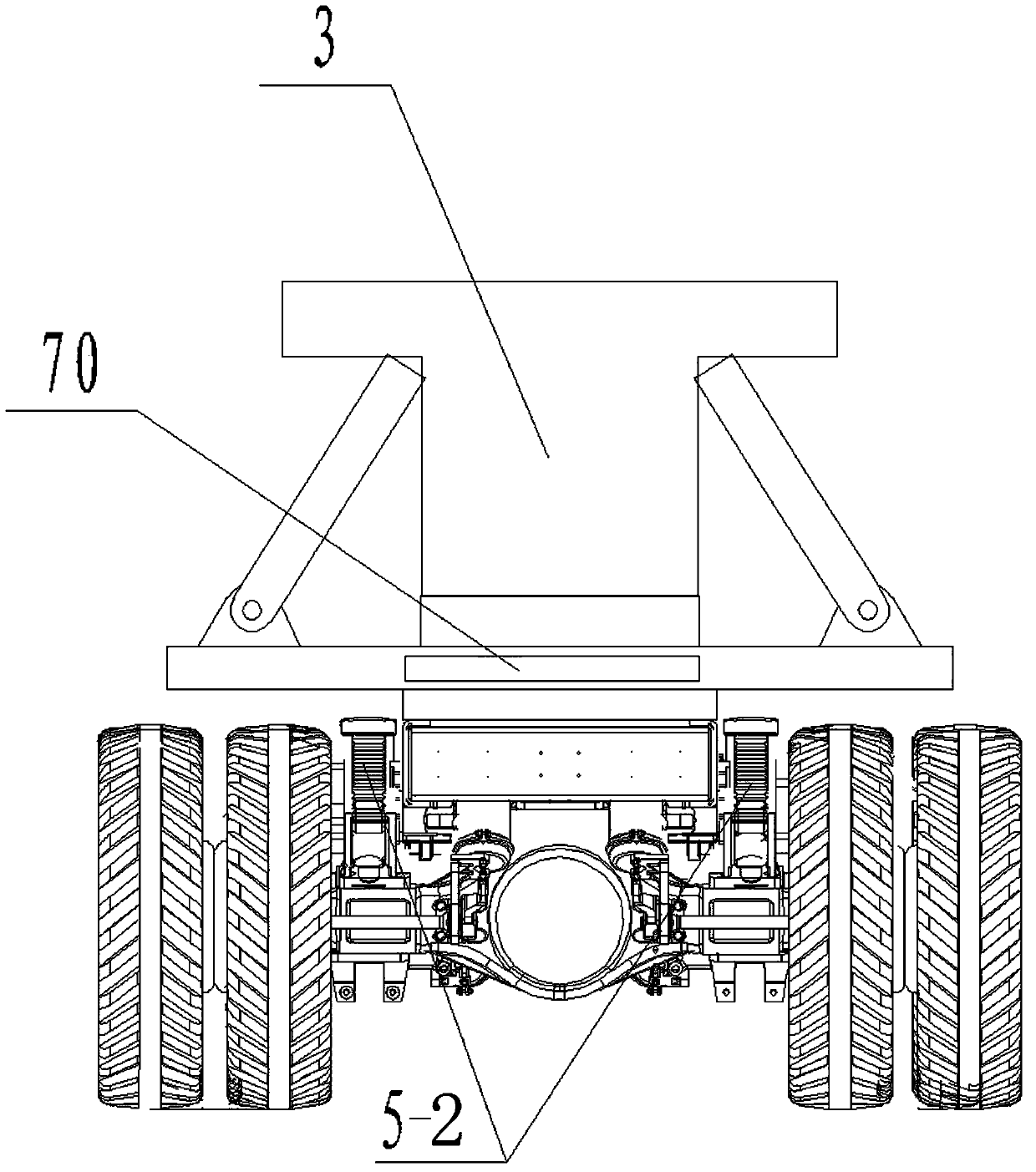

[0034] as attached figure 1 , 2 As shown, the railway T-beam special transportation equipment of the present invention comprises a main beam transporting machine 1 and an auxiliary beam transporting machine 2, and the main beam transporting machine 1 and the auxiliary beam transporting machine 2 are at least respectively equipped with 3 vehicle bridges, each Wheels are arranged at both ends of the axle;

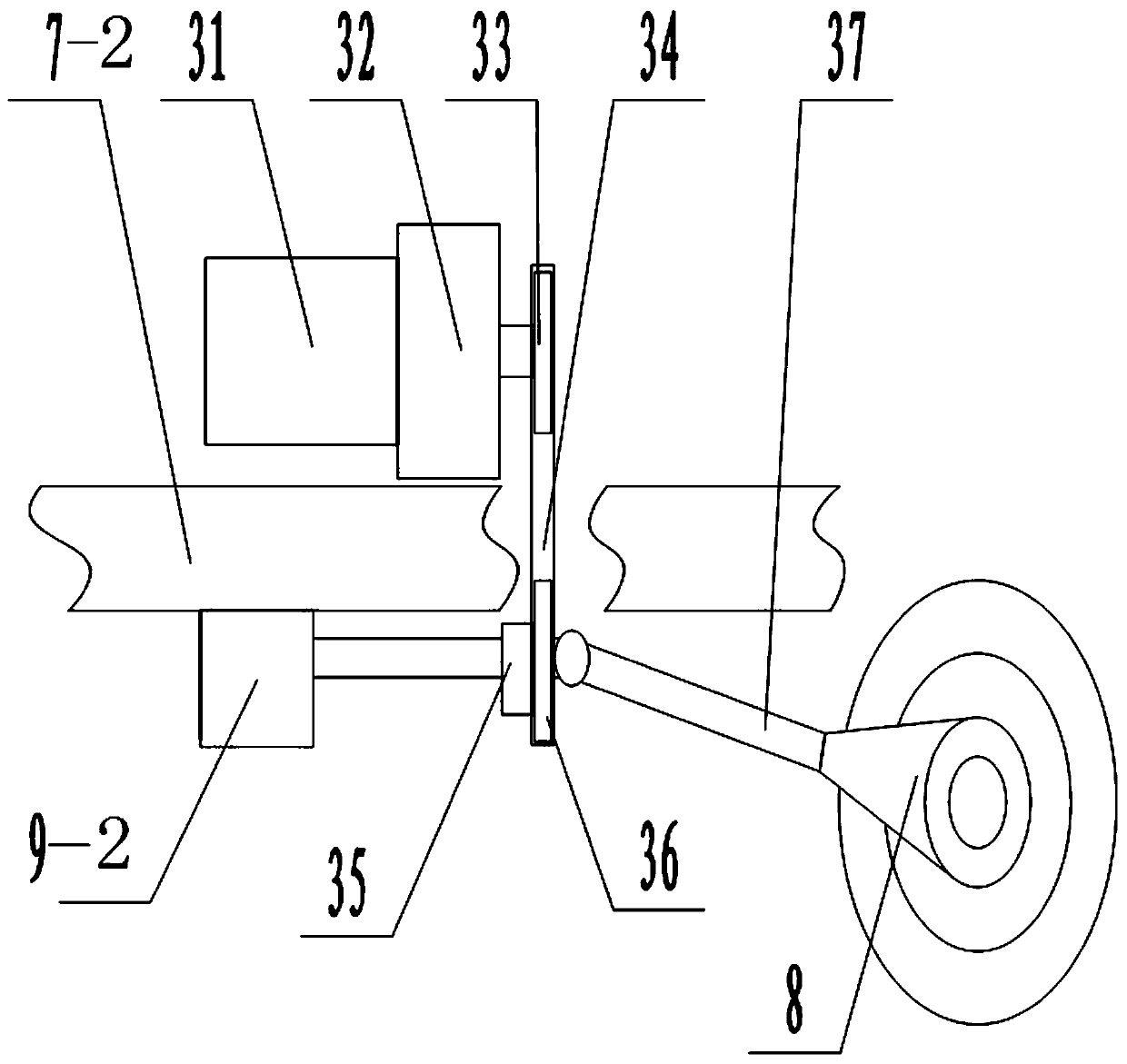

[0035] The main engine 9-1 is installed on the main frame 7-1 of the main beam transporting machine 1, the auxiliary engine 9-2 is installed on the subframe 7-2 of the auxiliary beam transporting machine 2, and the main beam transporting machine 1 has at least one The driving mechanism of the vehicle axle is connected with the main engine 9-1, and the auxiliary beam transporter 2 has at least one driving mechanism of the vehicle axle connected with the auxiliary engine 9-2. The main beam transporting machine 1 is provided with a main damping spring 5-1, and the auxiliary be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com