Method for minimizing total dissolved solids in industrial wastewater and system thereof

A technology of total dissolved solids and industrial wastewater, applied in chemical instruments and methods, water/sewage treatment, water/sewage treatment equipment, etc., can solve the problems of high cost, high cost, immovability, etc., to save space and save Processing time, versatile effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1)

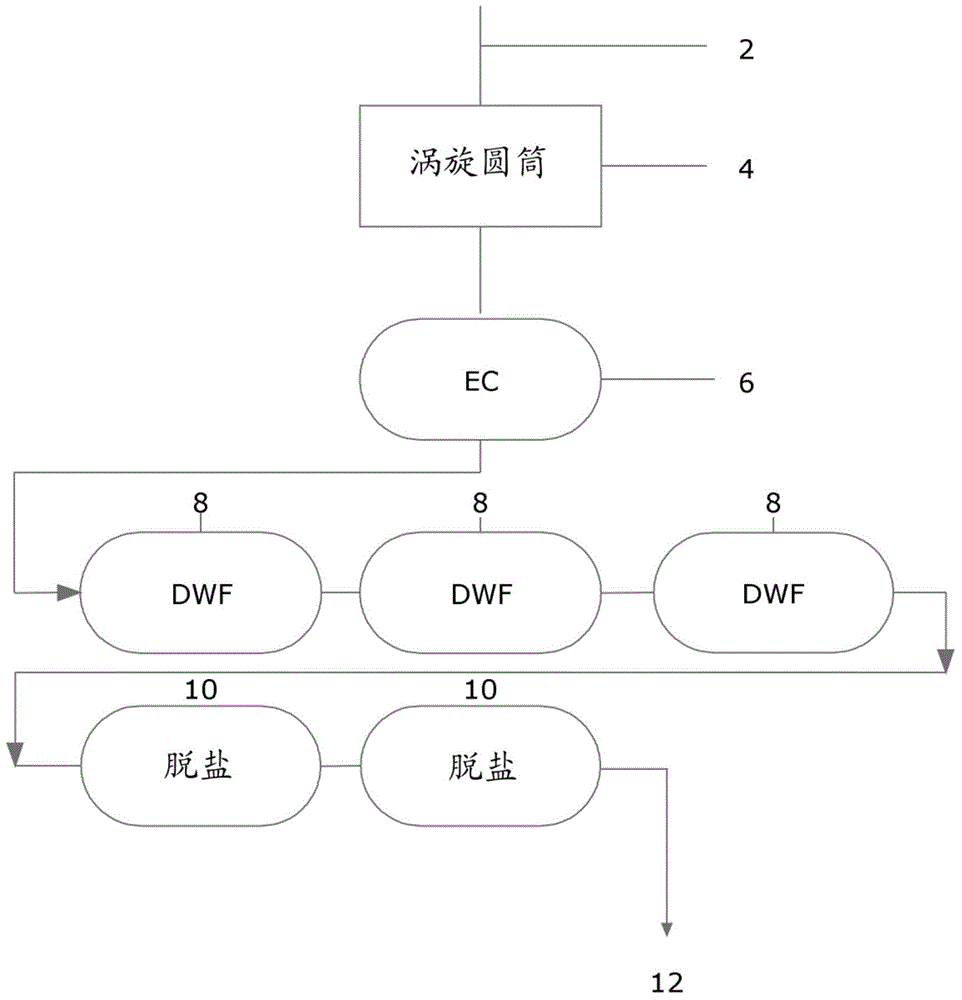

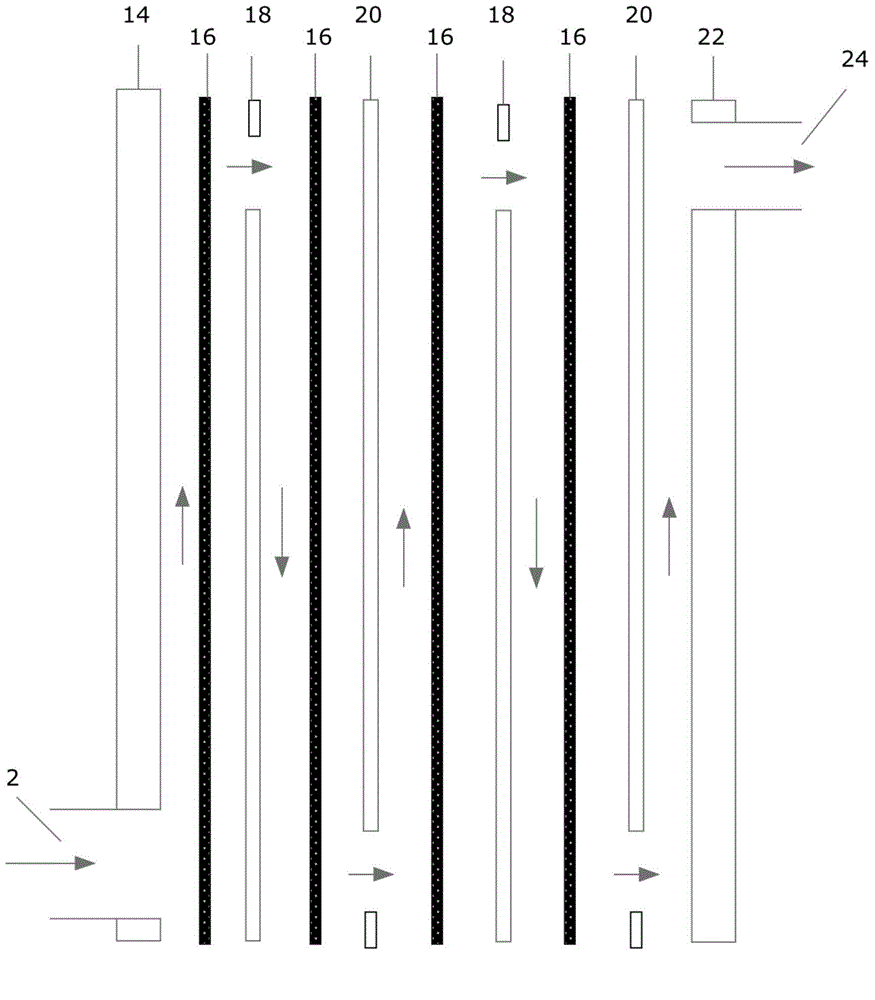

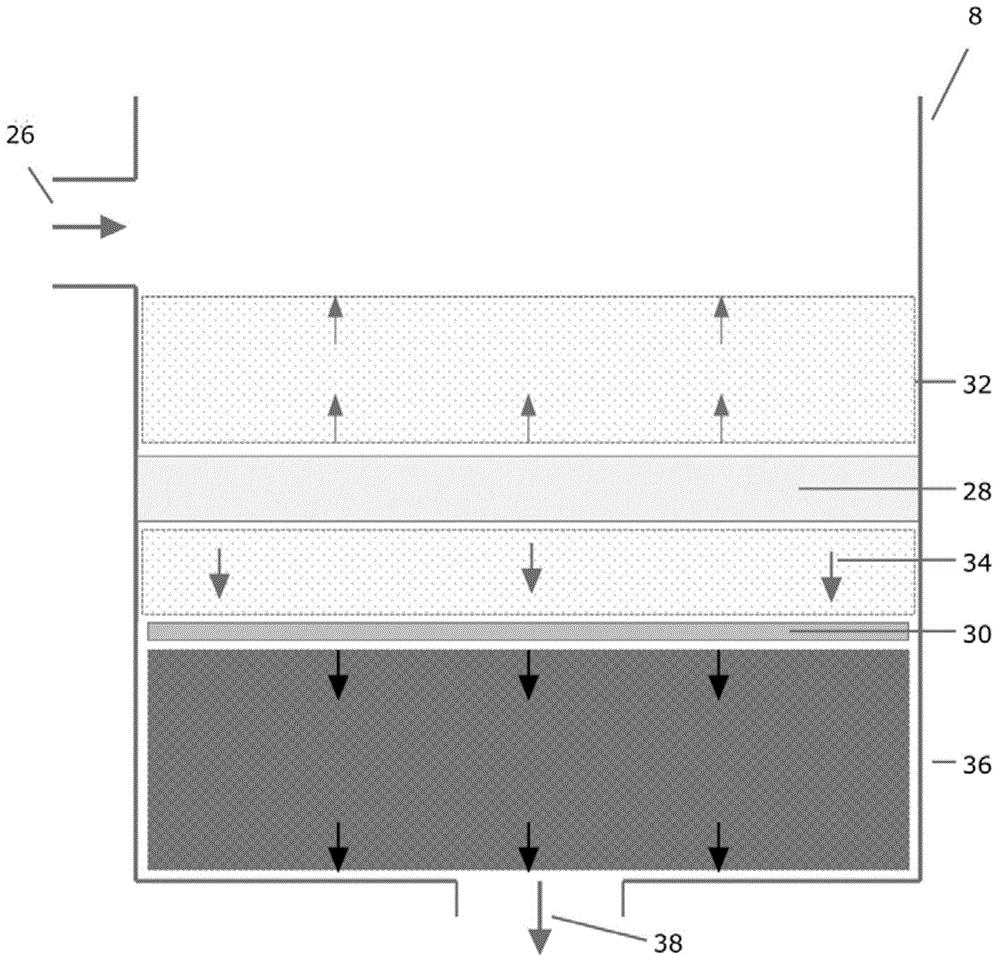

[0054] See Figure 1-7

[0055] Embodiments of the present invention will be described herein with reference to the accompanying drawings. In the following description, well-known functions or constructions are not described in detail to avoid obscuring the invention in unnecessary detail.

[0056] The present invention relates to a method and an apparatus in which a wastewater stream containing organic or inorganic substances has an effect on the ionic charge and in which dissociation of molecular compounds takes place. Therefore, when a fluid with ions is used to generate micron-sized hydrogen and oxygen bubbles, an applied electric field is utilized to increase the interface potential between the anode and cathode pair. This electric field is generated using one or more DC power sources electrically connected to the anode and cathode electrode pairs.

[0057] In some aspects of the invention, an electrode may comprise a group configured in a vertical or horizontal positi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com