Production process of glass fiber reinforced plastic septic tank and production equipment for glass fiber reinforced plastic septic tank

A technology of glass tempering and production technology, which is applied in the field of septic tank processing technology and septic tank equipment, can solve the problems of cumbersome process, unsatisfactory production efficiency and yield, and inconvenient operation, and achieve simple and reasonable process, high yield and Improvement in production efficiency and strong practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

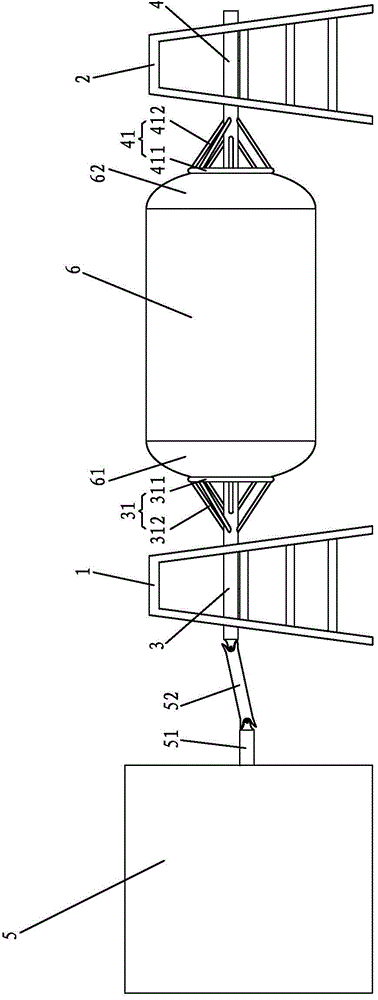

Image

Examples

Embodiment Construction

[0039] In order to further explain the technical solutions of the present invention, specific examples are given below to illustrate in detail.

[0040] A kind of production technology of FRP septic tank of the present invention, comprises the steps:

[0041] (1) Prepare resin glue, cut cloth to make fiber, impregnate winding fiber in resin glue to make winding fiber; make scraper, dividing plate and quartz sand;

[0042] (2) Combine the head base body with the winding fiber to make a head, and roll the above-mentioned scraper into a septic tank shell;

[0043] (3) the above-mentioned dividing plate and the head are inlaid together with the above-mentioned septic tank cylinder blank to make a mandrel;

[0044] (4) winding the above-mentioned winding fiber on the above-mentioned mandrel with a corresponding winding method to form an inner winding layer;

[0045] (5) impregnating and winding the sand cloth wrapped with the above-mentioned quartz sand and the resin glue on the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com