An h-shaped steel structure member and a circular steel column space oblique rigid joint connection node

A technology of round steel pipe columns and structural components, which is applied in the direction of building construction and construction, and can solve the problems that cannot be connected together, and the traditional structure is not feasible, etc., to achieve effective transmission of bending moment, reliable welding technology, and simple form Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be described in detail below with reference to the accompanying drawings and specific embodiments. This embodiment is implemented on the premise of the technical solution of the present invention, and provides a detailed implementation manner and a specific operation process, but the protection scope of the present invention is not limited to the following embodiments.

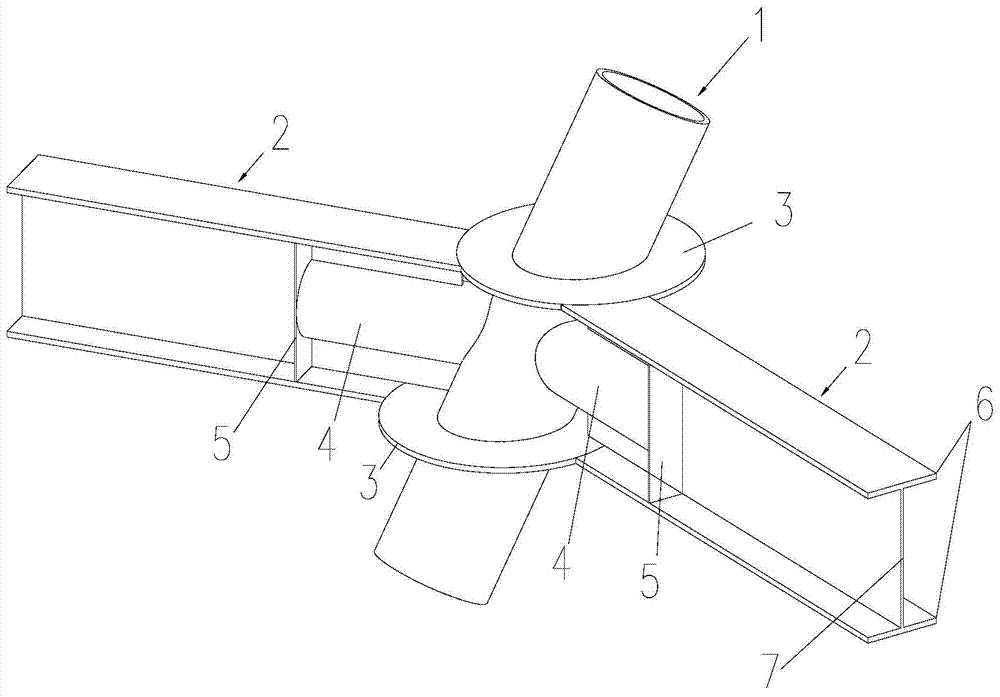

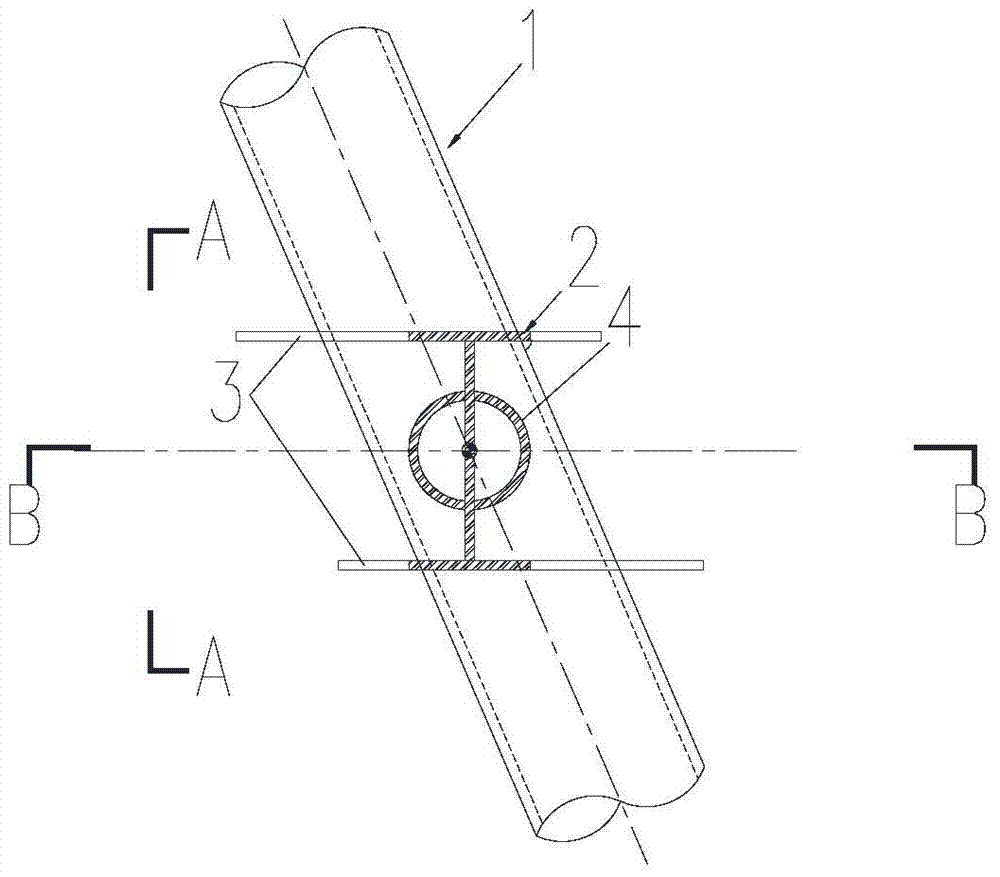

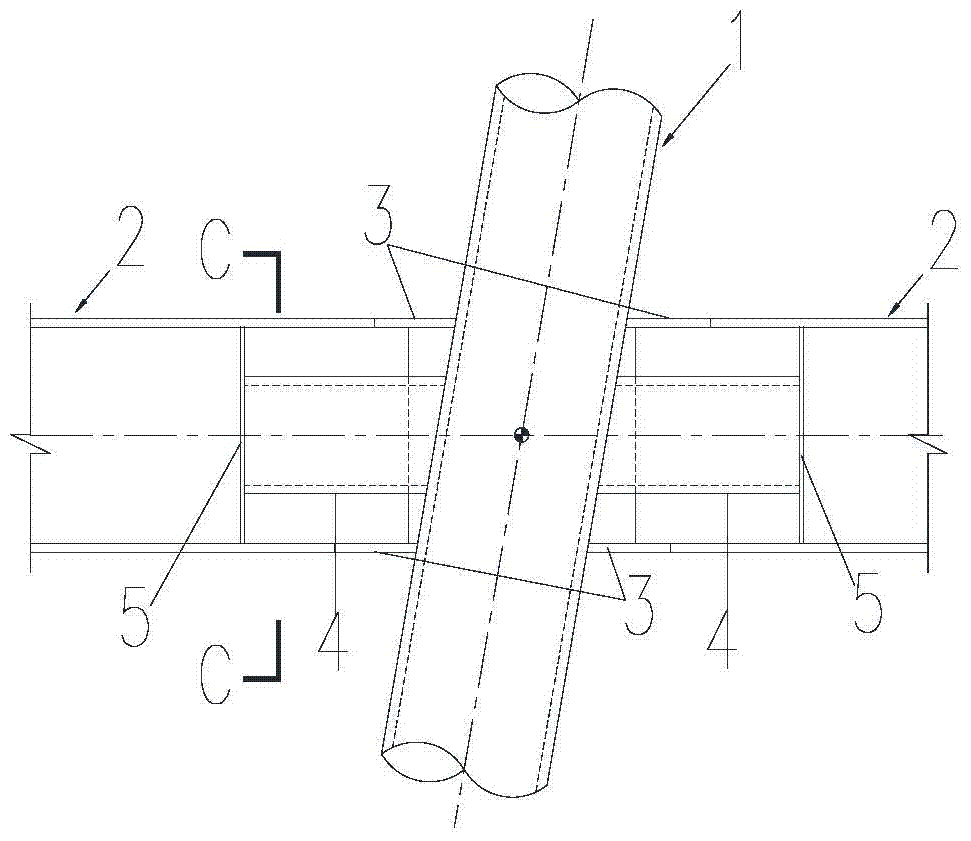

[0025] This embodiment provides a space oblique rigid connection connection between the H-shaped steel member of the steel structure and the circular steel tube member, such as Figures 1 to 5 As shown, it includes a round steel pipe column 1, an H-shaped steel beam 2, an external ring plate 3, a conversion steel pipe 4 and a head steel plate 5. The round steel pipe column 1 is arranged obliquely and intersects with the H-shaped steel beam 2 which is arranged horizontally and has a certain angle in space. The two external ring plates 3 are sheathed on the round steel pipe col...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com