Quick-laying light electric heating floor heating base plate system unit and laying method thereof

A system unit and electric heating technology, applied in the direction of electric heating system, heating method, heating system, etc., can solve the problems of low integration, high maintenance cost, difficult construction, etc., and achieve high indoor space and high product integration , On-site construction quick effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] Below in conjunction with accompanying drawing, the present invention will be further described:

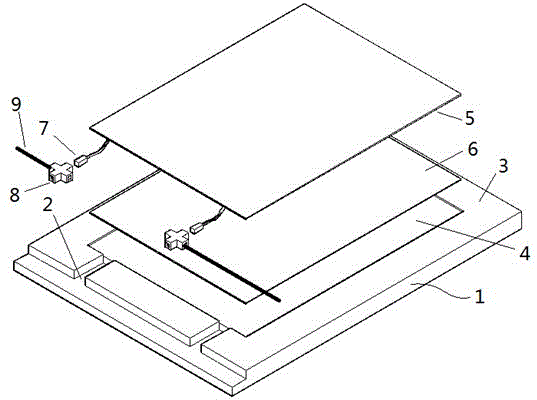

[0014] Such as figure 1 As shown, the present invention has a thermal insulation substrate 1, which is a PVC foamed crust board of 1200mm*600mm, and a power line positioning groove 2 is opened on one side of the width direction, and the surrounding area of the substrate is set as a pneumatic nail gun. The ground riveting area 3, and the middle area is the electric heating film positioning and installation area 4; there is a low-temperature electric heating film 5 of polymer nanomaterials in this area, which is pasted together with the heat preservation substrate 1 with double-sided adhesive 6; A quick joint 7 is installed on the power connection end of the film 5, which is connected with a cross power line connection seat 8 to form a parallel power connection system.

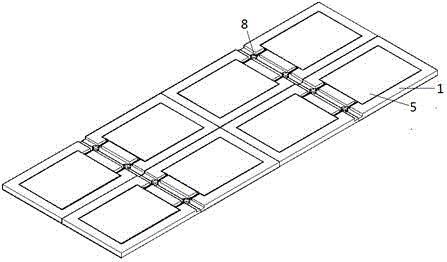

[0015] Such as figure 2 As shown, when paving, the method is:

[0016] 1. Check the flatness of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com