Automatic anti-backfire device for pasty propellant rocket motor

A rocket engine and paste propellant technology, which is applied to rocket engine devices, jet propulsion devices, machines/engines, etc., can solve the problems of energy consumption, inability to realize automatic control, and inability to realize large-scale flow adjustment, etc., to achieve layout Reasonable, compact structure, small footprint effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

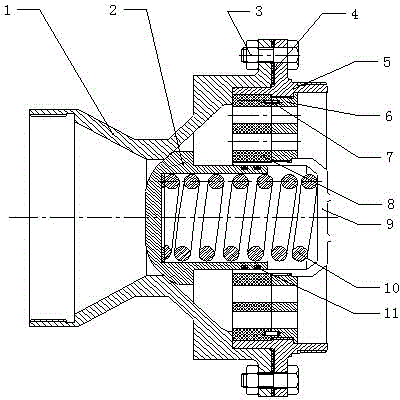

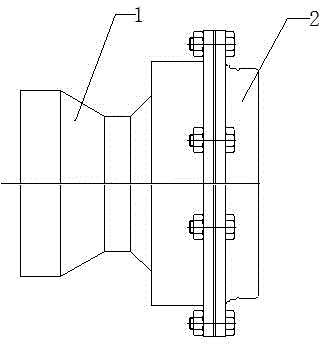

[0019] An anti-backfire device applied to a paste propellant rocket engine, comprising a casing 1, an orifice plate seat 5, an orifice plate 6, a heat-insulating orifice plate 8, a piston sleeve 9, an elastic element 10 and an anti-backfire piston 2.

[0020] The shape of the inner wall of the shell 1 is first contracted and then expanded (one end shrinks and the other end expands). The expanded end face of the inner wall of the shell 1 is connected with the orifice plate seat 5 by bolts to form the outer shell of the anti-tempering device. The shell 1 and the orifice plate The connecting surface of the seat 5 is provided with a gasket 4 to ensure good sealing between the two. The inner wall of the expansion end of the housing 1 is provided with a stepped surface. One end of the shrinking inner wall of the housing 1 is connected to the propellant storage tank. The other end of the orifice plate seat 5 is connected with the combustion chamber casing.

[0021] The orifice plat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com