Liquid cooling LED optical module

A liquid-cooled heat dissipation and optical module technology, applied in the field of optical modules, can solve problems such as insufficient contact surface, increased cost, increased thermal resistance, etc., and achieve the effect of direct heat dissipation, guaranteed service life, and good heat conduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

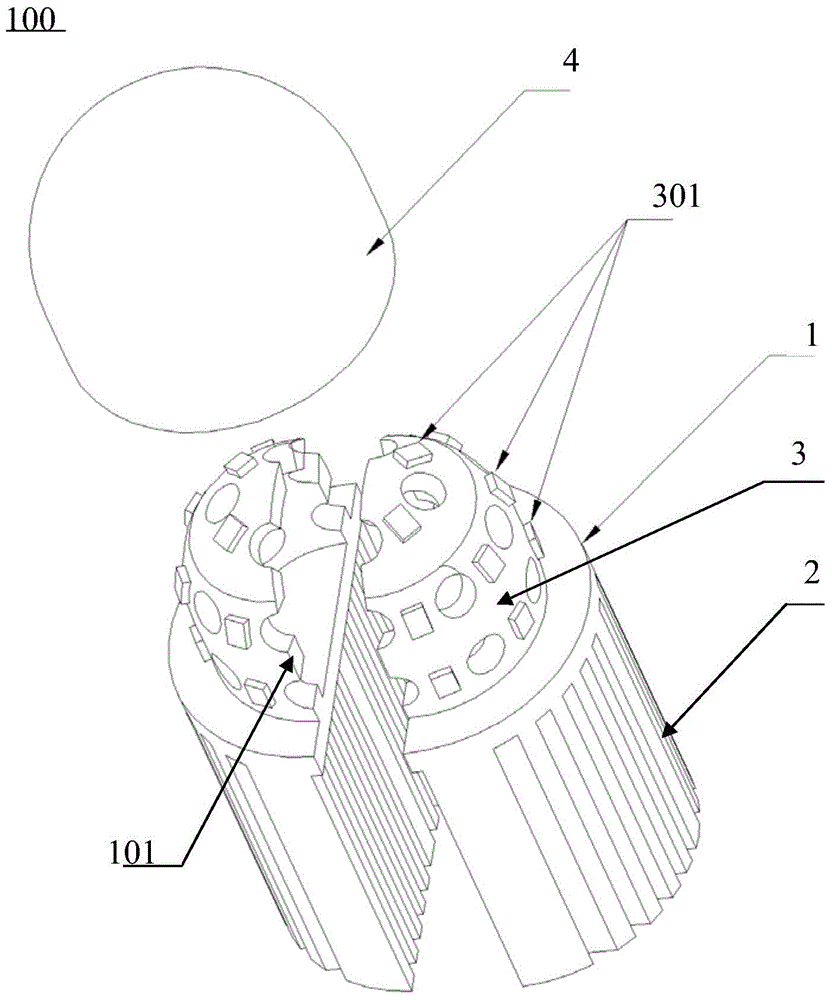

[0028] image 3 A front view schematically shows a liquid-cooled and heat-dissipating LED light module according to an embodiment of the present invention. according to image 3 It can be seen that the LED light module includes a light emitting cover 4 and a heat sink 2. The heat sink has a plurality of fins 201. See Figure 5 , The radiating fins have the same axial length but different radial lengths, and the radiating fins 201 are arranged in parallel in the axial direction; Figure 5 It shows a usage posture of the LED light module of the present invention. Figure 4 It can be seen that the general appearance shape of the LED light module of the present invention is generally a rod-shaped body with a hemispherical end.

[0029] See below figure 1 with figure 2 The liquid-cooled heat dissipation LED light module of the present invention is described in detail.

[0030] figure 1 An exploded view schematically shows a liquid-cooled and heat-dissipating LED light module accordi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com