High-temperature vacuum sintering furnace with automatic thermocouple plugging and unplugging device

A high-temperature vacuum and thermocouple technology, applied in furnaces, muffle furnaces, cooking furnaces, etc., can solve problems such as damaged thermocouples and inaccurate temperature measurement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

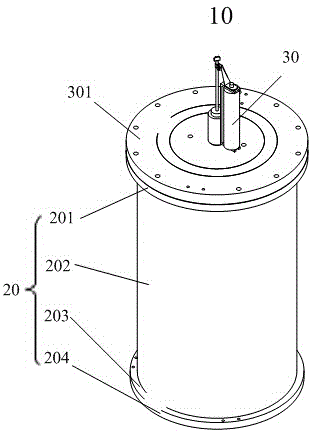

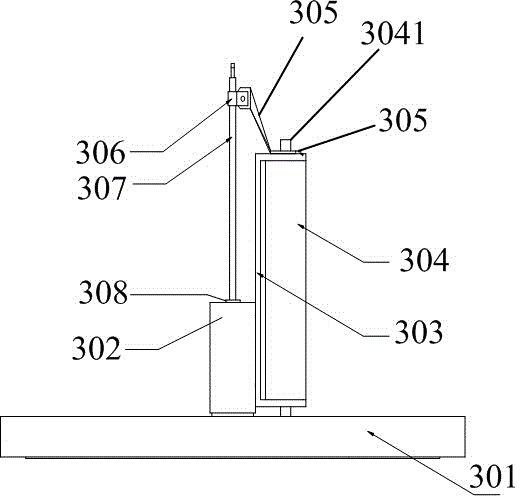

[0013] see Figure 1 to Figure 3 , the high-temperature vacuum sintering furnace 10 with an automatic thermocouple insertion device includes a furnace body 20 and an automatic thermocouple insertion device 30 disposed on the furnace body.

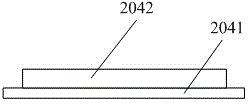

[0014] The furnace body 20 includes an upper flange 201 of the furnace body, a furnace cylinder 202 with an opening at one end, a lower flange 203 of the furnace body and a fixed flange 204. The furnace cylinder 202 is a hollow cylinder, and the upper flange 201 of the furnace body is fixedly arranged on the furnace cylinder 202 The top of the furnace body lower flange 203 is fixedly arranged on the open end of the furnace tube 202, and the diameter of the fixed flange 204 is the same as that of the furnace body lower flange 203. When the furnace body lower flange 203 is in phase with the fixed flange 204 When in contact, the furnace drum 202 and the fixing flange 204 form a closed space. In this embodiment, see Figure 4 The fixed flange...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com