Trilateral spiral twisted band

A technology of helical ties and spirals, applied in the field of new three-sided helical ties, can solve the problems that the comprehensive performance needs to be further improved, the fluid flow resistance is increased, etc., and achieve the effect of strong turbulence effect, increased fluid flow, and sufficient heat exchange.

Inactive Publication Date: 2015-07-22

ZHENGZHOU UNIV

View PDF7 Cites 9 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Compared with ordinary torsion, although the strengthening effect of the special-shaped bond has been improved to a certain ext

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Login to View More

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Angle | aaaaa | aaaaa |

Login to View More

Abstract

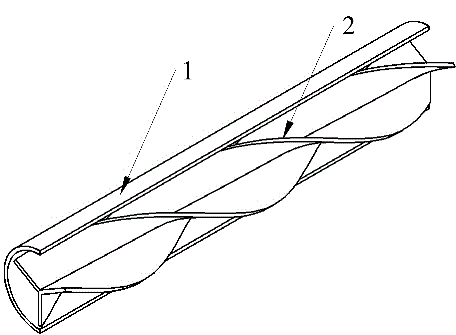

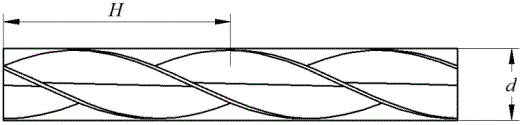

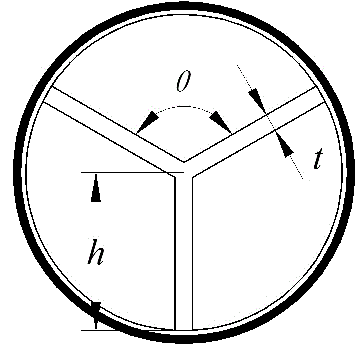

The invention discloses a trilateral spiral twisted band. The trilateral spiral twisted band is characterized in that the trilateral spiral twisted band is of a periodic structure and is formed by three width-equal metal sheets with the thickness of being about 1 mm, long edges of the three metal sheets are welded together in a butt joint mode, and the included angle between every two adjacent metal sheets is 120 degrees; the trilateral spiral twisted band is formed in a spiral twisting and fabricating mode, and the twisting rate of the trilateral spiral twisted band is about 2.0; the outer diameter of the trilateral spiral twisted band is 0.5 mm-1.0 mm smaller than the inner diameter of a heat exchange pipe, and the length of the trilateral spiral twisted band is generally equal to or smaller than that of the heat exchange pipe; the trilateral spiral twisted band is inserted into the heat exchange pipe without a fixing device; materials for the trilateral spiral twisted band are determined according to specific working conditions; as for occasions with corrosive media, stainless steel can be selected for the trilateral spiral twisted band, and the trilateral spiral twisted band can also be formed in a plastic injection moulding mode; as for occasions without corrosive media, plain carbon steel is selected for the trilateral spiral twisted band. The trilateral spiral twisted band is simple in structure and convenient to install, can be directly inserted into the heat exchange pipe, has dual functions of strengthening of heat transfer of fluid in the pipe and scale prevention, and is good in economical efficiency and high in practicability.

Description

technical field [0001] The patent of the present invention relates to an insert in a pipe, that is, a tie, in particular to a new type of trilateral spiral tie used in a heat exchange pipe to enhance fluid heat exchange and prevent fouling. Background technique [0002] Heat exchange equipment is widely used in petroleum, chemical, power, nuclear energy, metallurgy, refrigeration and other industries, and is a basic equipment for heat transfer. For example, in an oil refinery, heat exchange equipment accounts for about 35% to 40% of all process equipment investment, and the efficiency of heat exchange equipment is of great significance to energy saving. It is an important topic in the current research field of heat exchangers to adopt enhanced heat transfer technology and improve the efficiency of heat exchangers. [0003] Among the many enhanced heat transfer measures, the advantages of using in-tube enhanced heat transfer elements such as coil springs, helical sheets, rot...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): F28F13/12

Inventor 吴金星王超刘艳会王明强李亚飞彭旭栗俊芬

Owner ZHENGZHOU UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com