A kind of micro tension test device between two cohesive particles

A tensile test and particle technology, applied in the direction of analyzing materials, instruments, etc., can solve the problems of inconvenient theoretical analysis, complicated use structure, inability to record the change process of two particles, etc., to achieve the effect of convenient theoretical analysis and reasonable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] Below in conjunction with accompanying drawing and example the present invention will be further described:

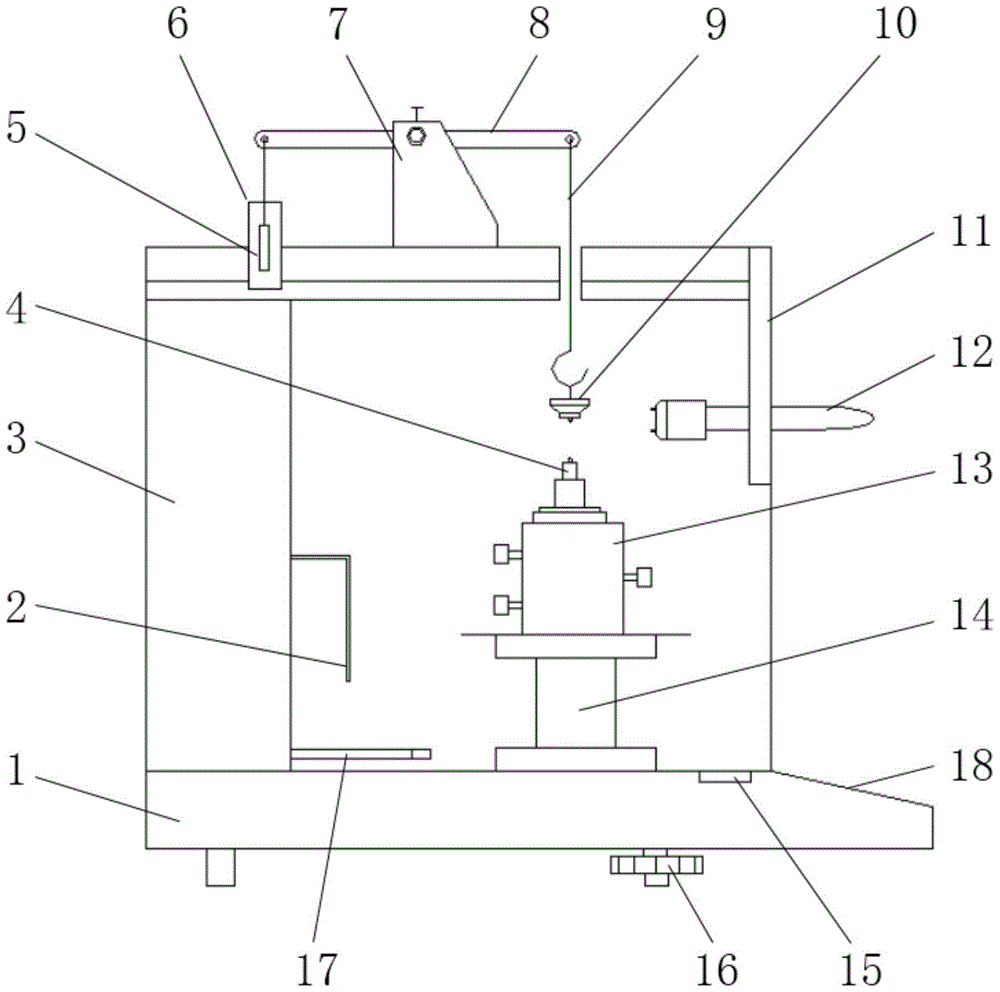

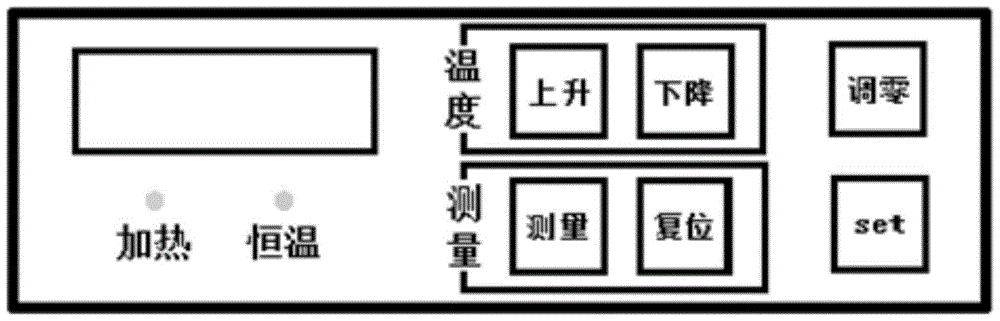

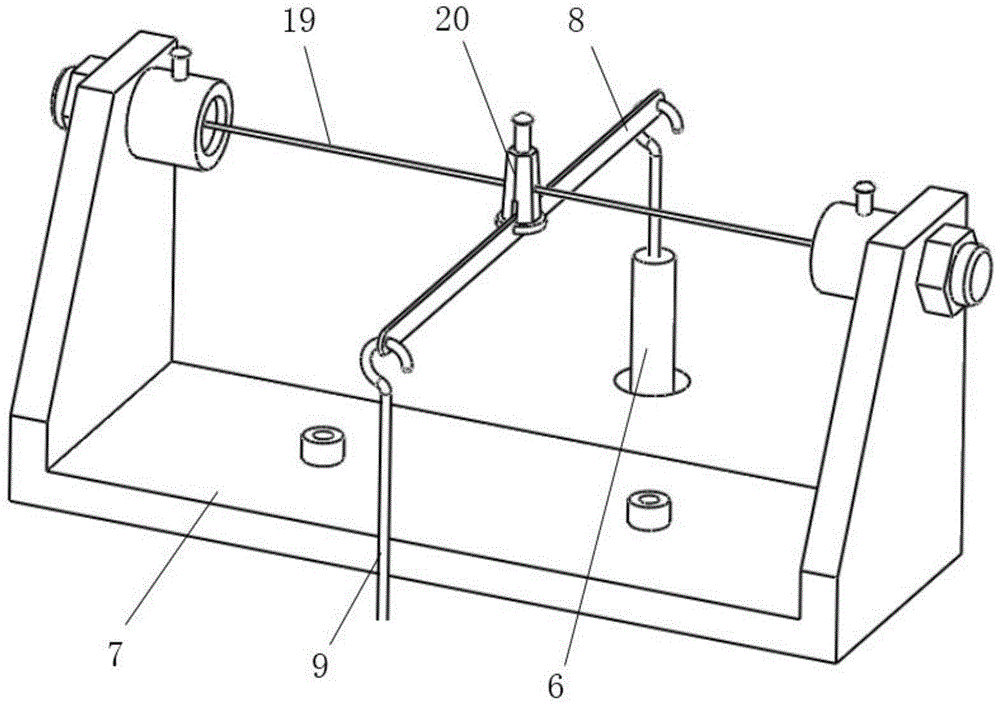

[0013] Such as Figure 1-3 As shown, the present invention is a micro tension test device between two viscous particles, including a base 1, a temperature sensor 2, a circuit conversion device 3, a lower particle carrier 4, a sensor core 5, a displacement sensor 6, a lever frame 7, and a lever arm 8. Hook 9, upper particle carrier 10, microscope centralizer 11, high-definition electron microscope 12, fine-tuning platform 13, lifting platform 14, level bubble 15, leveling knob 16, constant temperature heating device 17, control panel 18, torsion wire 19, The torsion wire connection frame 20, the circuit conversion device 3, the lifting platform 14 and the vial 15 are fixedly connected on the base 1, the temperature sensor 2 and the constant temperature heating device 17 are fixedly connected on the circuit conversion device 3, the described The fine-tuning platf...

PUM

| Property | Measurement | Unit |

|---|---|---|

| radius | aaaaa | aaaaa |

| radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com