Revolution speed adapter plate for turbine

A technology of steam turbines and adapter plates, which is applied in the direction of devices using electric/magnetic methods, can solve the problems of difficulty in balancing accuracy and reliability, and achieve the effect of avoiding inaccurate low-speed measurement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

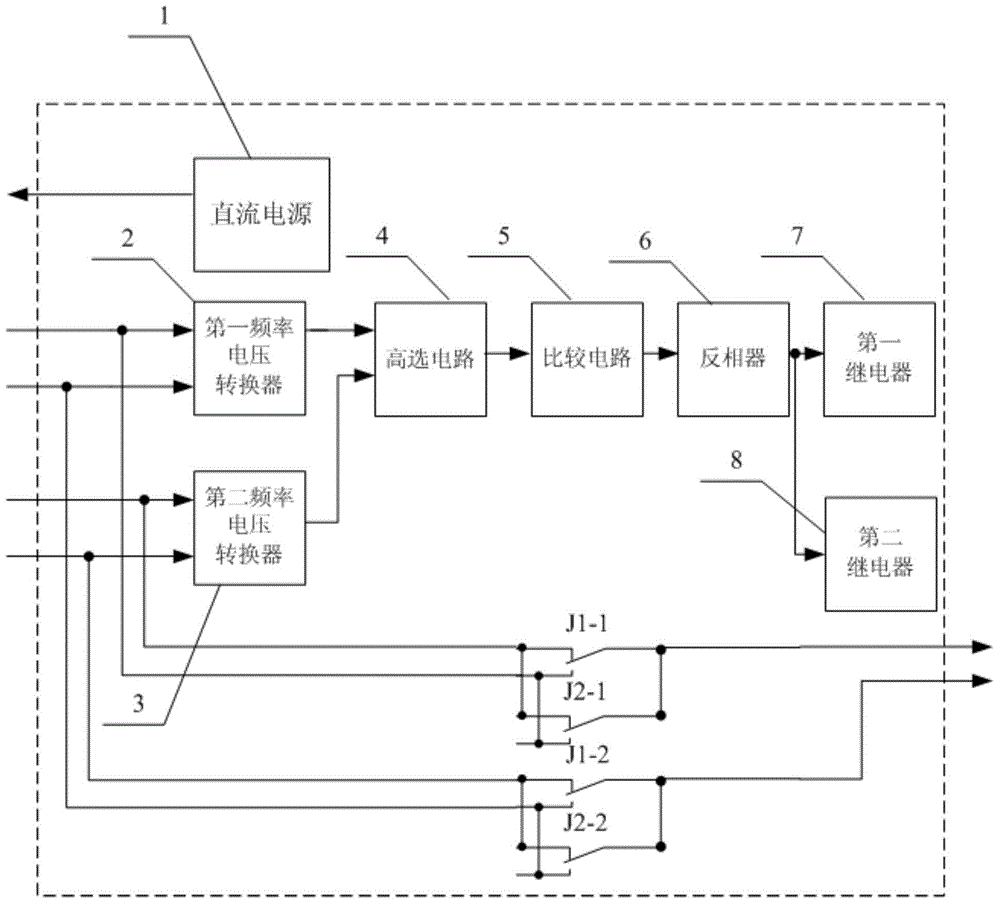

[0019] Specific implementation mode one: the following combination figure 1 and figure 2 Describe this embodiment, the steam turbine speed adapter board described in this embodiment includes a DC power supply 1, a first frequency-to-voltage converter 2, a second frequency-to-voltage converter 3, a high-selection circuit 4, a comparison circuit 5, and an inverter 6. The first relay 7 and the second relay 8,

[0020] DC power supply 1 is used to provide working power for the eddy current speed sensor;

[0021] The positive input end of the first frequency voltage converter 2 is connected to the pulse signal positive output end of the eddy current speed sensor, and the negative input end of the first frequency voltage converter 2 is connected to the pulse signal negative output end of the eddy current speed sensor;

[0022] The positive input end of the second frequency voltage converter 3 is connected to the positive output end of the unequal amplitude sine wave signal of the...

specific Embodiment approach 2

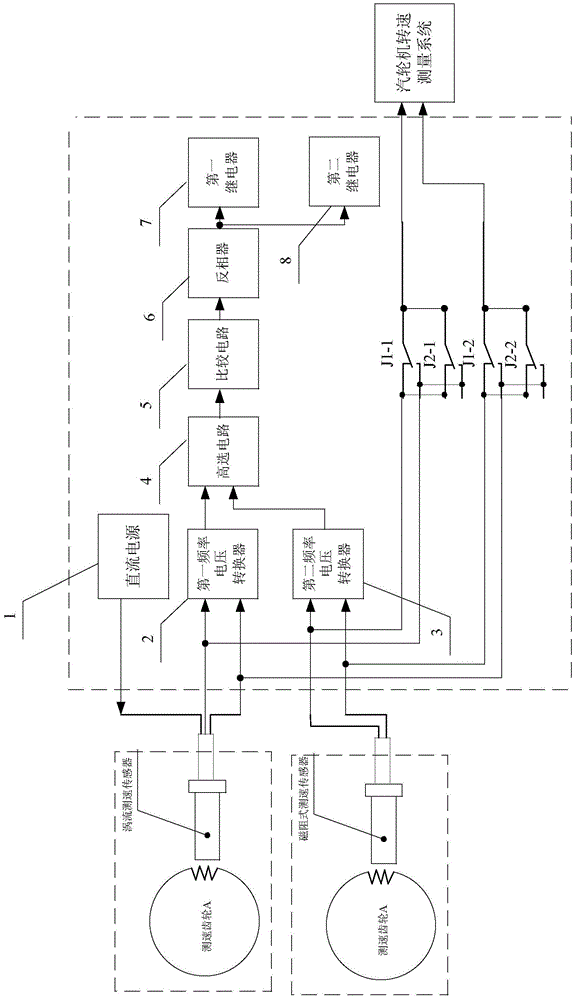

[0032] Specific implementation mode two: the following combination figure 2 This embodiment will be described. This embodiment will further describe the first embodiment. The voltage threshold set by the comparator circuit 5 is the corresponding voltage value when the steam turbine speed is 500 RPM.

[0033] When the rotation speed is greater than 500 rpm, the two relays are controlled to lose power, the normally open contacts of the relays are disconnected, and the normally closed contacts are closed. When it is equal to 500 revolutions, the pulse signal of the eddy current speed sensor is output.

[0034] figure 2 As shown, the steam turbine eddy current speed sensor enters the first channel of the adapter board, the DC power supply of the eddy current speed sensor is provided by the steam turbine speed adapter board, and the steam turbine reluctance speed sensor enters the second channel of the adapter board, and the steam turbine speed is low When the speed is at or eq...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com